This article appeared in Machine Design and has been published here with permission.

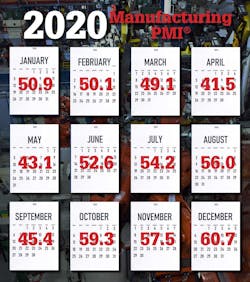

Manufacturing’s whipsaw year of contraction and growth finished on the highest note in December, as the monthly Institute for Supply Management’s (ISM) PMI Index jumped to 60.7%. The index finished 2020 on an eight-month streak of recovery after collapsing in April at the outset of the COVID-19 pandemic.

Sharp increases in new orders and production fueled the jump of 3.2 percentage points from the 57.5% reading in November. From its low point of 41.5% in the April reading, which ended 12 years of economic growth, the PMI has steadily recovered. The big jump was a 9.5 percentage point increase in June from 43.1% to 52.5%, bringing the index back above the 50% threshold for growth and halting three months of decline. The 60.7% level in December indicates 20% growth over the baseline for manufacturing sector growth.

Since then, manufacturing optimism has gradually recovered along with the index. “Committee members reported that their companies and suppliers continue to operate in reconfigured factories,” said Timothy R. Fiore, chairman of ISM’s Manufacturing Business Survey Committee. “but absenteeism, short-term shutdowns to sanitize facilities, and difficulties in returning and hiring workers are causing strains that are limiting manufacturing growth potential.

“However, panel sentiment remains optimistic [three positive comments for every cautious comment], an improvement compared to November,” Fiore added.

Two keys areas in the PMI account for much of that optimism. The New Orders Index hit 67.9%, up 2.8 percentage points from the November reading of 65.1%, and the Production Index was at 64.8%, up 4 percentage points from the November reading. In addition, 16 of the 18 industry markets expanded in December, including the six largest: Fabricated Metal Products; Computer & Electronic Products; Transportation Equipment; Chemical Products; Petroleum & Coal Products; and Food, Beverage & Tobacco Products.

“Manufacturing performed well for the seventh straight month, with demand, consumption and inputs registering strong growth compared to November,” Fiore sad. “Labor market difficulties at panelists’ companies and their suppliers will continue to restrict the manufacturing economy expansion until the coronavirus crisis ends.”

Committee members echoed the optimism and the concerns in the monthly report. Among the comments:

- “Our company and industry are continuing to have tailwinds from the COVID-19 pandemic research support for vaccines and treatments. While our services are delayed, many customers are not cancelling outright, and business picked up for us in the last month — especially in China, where business growth is back on track.” (Computer & Electronic Products)

- “Continued to survive COVID-19 shutdowns, customer restrictions and personnel issues (work from home and COVID-19 outbreaks) and managed to maintain slight growth over 2019.” (Chemical Products)

- “COVID-19 outbreaks are causing supply chain issues for Tier-1 and Tier-2 suppliers. More work needs to ensure suppliers keep us in the loop with any problem in their supply chain. But end-customer demand for products is keeping production and future outlook positive.” (Transportation Equipment)

- “COVID-19 is affecting us more strongly now than back in March. Vendors/service suppliers unable to maintain levels of service due to employee shortages. Logistic issues also hurting us due to coronavirus-related problems.” (Food, Beverage & Tobacco Products)

- “Current business outlook is strong through the first quarter of 2021. We are anticipating 20% growth in sales for 2021.” (Fabricated Metal Products)

- “Sales are now slightly above pre-COVID-19 sales.” (Machinery)

- “Sales are now exceeding pre-COVID-19 levels, but uncertainty remains through the winter months while COVID-19 is still rampant.” (Miscellaneous Manufacturing)

- “Business is stronger than expected, with higher demand for many products. Volatility continues due to the very persistent pandemic and associated risks.” (Electrical Equipment, Appliances & Components)

- “Suppliers are having difficulty finding and retaining labor leading to supply constraints.” (Plastics & Rubber Products)

- “Fourth-quarter production improved more than anticipated, both against the rolling forecast and compared to typical Q4 business.” (Primary Metals)

About the Author

Bob Vavra

Senior Content Director, Power & Motion and Machine Design

Bob Vavra is the Senior Content Director of Power & Motion and its sister publication Machine Design. Vavra has had a long career in publishing, media and events. He has covered all aspects of manufacturing for the past 20 years and is a regular attendee at events such as IMTS and Hannover Messe. Vavra is also a sought-after webcast moderator and event emcee, and has presided over events in the U.S., Germany and China.