Electrohydraulic system powers high-production sand molding machines

In 1914, Elmer Beardsley and Walter Piper conceived the idea of mechanically throwing sand — a concept that revolutionized the foundry industry. In subsequent years, Beardsley and Piper became the inventors and builders of Sandslingers, which changed large mold making from a backbreaking operation to an efficient mechanized process.

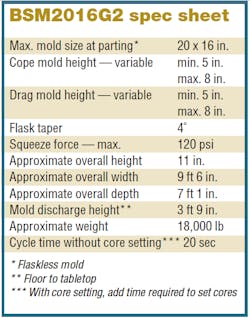

Today, Beardsley & Piper LLC, is part of the Simpson Group owned by Simpson Technologies Corp., Aurora, Ill. Beardsley & Piper developed the BSM2016G2 Series Matchblomatic, an automatic matchplate molding machine that produces ready-to-pour flaskless green sand molds. One machine is said to offer the productivity of three to five industry-standard jolt-squeeze molders and requires only slightly more space than a single jolt-squeeze machine. The first-generation Matchblomatic was the first matchplate machine to use a blow-squeeze molding method to produce uniform high-quality molds. The BSM2016G2 produces up to 180 molds per hour with the precision of a machine tool, thanks to a simplified design.

The hydraulics package

According to Boris Shiller, Beardsley & Piper engineering manager, more than 500 of the earlier designs of the Matchblomatic are still in use today in all types of foundries around the world. The new Matchblomatic Series features a semi-enclosed design, independently variable cope and drag height, an updated proportional control system, quick change pattern features, automatically adjustable blow pressure, larger volume sand magazine, a butterfly valve sand gate, an automatic spray pattern, and a fully updated control and operator interface scheme.

The machine's hydraulic system was designed and built by Flodyne/Hydradyne Inc., a Bosch Rexroth distributor, system designer, and integrator located in Hanover Park, Ill. The hydraulic system includes a custom hydraulic power unit (HPU) incorporating an 80-gal reservoir and Bosch Rexroth 42-gpm maximum horsepower-limiting pump driven by a 30-hp, 1800-rpm electric motor. The high-pressure portion of the duty cycle is 3000 psi.

The pump was selected for its high efficiency, low noise, and reliability. Its horsepower-limiting option greatly reduced the size of the electric motor needed. Furthermore, it allows for a low-pressure standby operation of the machine to further consere energy.

Also included are three loose valve assemblies, which incorporate four Rexroth proportional valves, plus various other valves. Selection of these components was based on the recommendations of Flodyne/Hydradyne and Bosch Rexroth after they thoroughly reviewed Beardsley & Piper's design and performance requirements.

Synchronizing position

By incorporating a Rexroth digital servodrive, Beardsley & Piper was able to rapidly and precisely synchronize position while smoothly transitioning from position to force control mode on the cope and table actuators during the cycle's squeeze portion. The freely programmable, bus-capable controller is suitable for electromechanical and electrohydraulic drives, and offers true axis synchronization.

Due to open- and closed-loop control algorithms specifically tailored to the characteristics inherent to hydraulics, optimum performance of electrohydraulic drives is achieved. Sequences can be programmed via a PC, and NC programming provides flexibility and uses a common platform.

As a standard, each servodrive features a local CANbus, which can be used to link the individual drives for general data exchange or for implementing synchronization controls. This results in a scalable automation concept using modular principles. It can also communicate with higher-level controls via Profibus-DP, Interbus-S, and CANopen fieldbuses, and is available with SERCOS interface, the most common communication system for electric drives.

Putting on the squeeze

The digital servodrive produces a fast, controlled squeeze, which decreases the cycle time of the machine and increases mold output. It also eliminates mold pattern breakout by closely matching both cope and table squeeze forces and providing a menu-based automatic adjustment of pressures, forces, and hydraulic actuator velocities, as well as positions for the various patterns users might need. This automatic setup eliminates the need for manual adjustment of the machine, resulting in quicker and repeatable parameter changeover.

About the Author

Leaders relevant to this article: