Troubleshooting Challenge: Cargo Ship Pressure Buildup Problem

This file type includes high-resolution graphics and schematics when applicable.

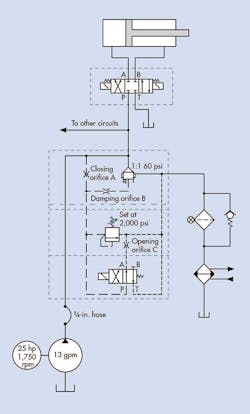

A cargo ship has a hydraulic power unit (HPU) that opens and closes several hatch doors on grain-storage areas. The accompanying schematic shows a circuit for one of eight cylinders and valves located close to the doors, with the HPU on a lower deck. The HPU is located midway between two sets of four. The pressure and return lines run approximately 200 ft. in each direction.

Every time operators wanted to open or close a door, it would take almost a minute holding the solenoid button before the pressure would reach a pressure that would start moving the cylinders. Once started, they moved as expected. However, releasing the button and pushing it again caused a one-minute delay before anything would move again.

The electrical system was simple. Pressing a button for any solenoid would also energize the solenoid on the unloading valve located on top of the main relief.

Bleeding air from the system did slightly reduce the delay. However, can you tell the main cause of the problem from the schematic?

Find the Solution

Think you know the answer to this month’s problem? Submit your solution by emailing Mindy Timmer at [email protected]. All correct solutions submitted by March 30, 2016, will be entered into a random drawing for a $50 gift card. The winner will be notified, and his or her name will be printed in a future issue. Only one gift card will be awarded to any participant within a calendar year.

Solution to Last Month’s Problem:

Mill Removal Circuit Doesn’t Move for Large Rolls

Regenerative circuits are used to increase the speed of a cylinder by routing fluid exiting the rod end back into the cap end. However, if the circuit remains in the regenerative mode when encountering a heavy load, the cylinder will be unable to apply full force unless rod-end fluid vents to tank.

The 0.020-in. orifice branching off the rod plumbing in was used to accomplish this bleed-down. They found this orifice plugged and once it was cleaned, the system worked well.

About the Author

Robert Sheaf

President

Robert J. Sheaf Jr., is the founder and president of CFC Industrial Training, formerly Certified Fluid Consultants, part of CFC-Solar Inc. CFC-Solar provides technical training, consulting, and field services to any industry using fluid power technology.