Engineering Essentials: Types of Speed-Control Circuits

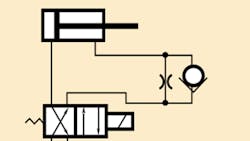

Speed control during a work stroke can be accomplished by regulating flow to the cylinder. The check valve allows free reverse flow when the cylinder retracts. It normally gives finer speed control than a meter-out circuit.

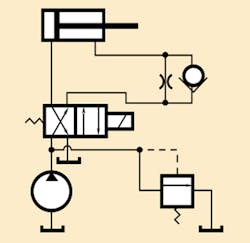

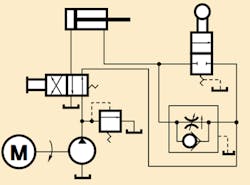

Meter-out circuit

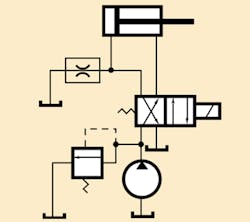

Regulating flow from the cylinder is another way to control speed. This circuit maintains a constant backpressure during rod extension and prevents lunging if the load drops quickly or reverses.Bleed-off circuit

Flow to the cylinder is regulated by metering part of the pump flow to tank. This circuit is more efficient than meter-in or meter-out, as pump output is only high enough to overcome resistance. However, it does not compensate for pump slip.Variable-volume pump

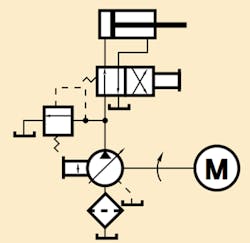

Pump flow can be controlled by various means such as manual, electric motor, hydraulic, or mechanical. How closely flow output actually matches command depends, in part, on slip, which increases with load. With a pressure-compensated, variable-volume pump, output flow decreases with the increasing pressure. This type of pump can be used for traverse and clamp operations. An external relief valve is usually unnecessary when a pressure-compensated pump is used. For details on the different types of pumps, their operation, and how they vary flow, refer to the pumps section of this Handbook.Variable feed

Many machines require intermittent fast and slow feed during their cycles. This can be accomplished by having a cam-operated 2-way valve in parallel with a meter-out flow control valve. Rapid forward movement takes place any time the 2-way valve is open. Closing off the valve slows down cylinder speed. Properly positioning the cams obtains the required speeds in sequence. The check valve in parallel with the flow control permits free return flow, allowing the cylinder rod to return rapidly.