Fluid power beams into Las Vegas

Ah, Las Vegas. Bright lights, casinos, fancy hotels, gorgeous year-round weather, top entertainment attractions, and fluid power. Fluid power? Yes, fluid power. Even if you haven't been to Las Vegas, you are sure to have heard of some of the massive construction projects that have been going on for the last several years — and there's no end in sight. In fact, by most accounts, Las Vegas is the fastest-growing city in the U.S.

But how does fluid power fit into all this? For one, hydraulics has a stronghold in most of the construction equipment that helps bring all these projects to fruition. Certainly much less visible are the contributions of hydraulics behind the scenes at many of these exciting new attractions.

A history of excitement

For example, the Treasure Island Hotel's Buccaneer Bay (covered in our December 1993 issue) uses powerful hydraulic drives to impart incredible realism to a make-believe naval battle. Hydraulics not only propels one ship through a Caribbean lagoon and makes another one sink, but generates the waves in the water as well.

One of the most well-known and longest running acts in Las Vegas is Siegfried and Roy at the Mirage Hotel (mentioned in our July 1992 issue). The climax of this act uses an intimidating fire-breathing dragon with 30 axes of electrohydraulic motion control. Electrohydraulic technology is also called on for motion of two other sophisticated dragons, each with 28 axes of motion, at the EFX show at the MGM Grand Hotel (covered in our July 1995 issue).

More recently, the Bellagio Hotel relies on hydraulics for critical segments of their Cirque du Soleil Show titled, simply, O (which is pronounced like the French word for water). This is a combination stage-water show, and hydraulics is used to raise four platforms up from under water -- 1½ million gallons of it. This is accomplished with three hydraulic cylinders for each platform through closed-loop proportional hydraulics to keep all motions synchronized with each other. This is no simple task, because the cylinders have strokes of well over 10 ft. Each set of cylinders is powered by a Vickers Integrated Motor Pump, from Eaton Corp.'s Industrial Hydraulics Div. These pump-motors are designed for quiet operation by using a liquid-cooled electric motor and pump encased in a sound-resistant enclosure. The quiet operation allows them to be located near the attraction without the risk of the audience hearing them operate.

Still another attraction — the High Roller coaster atop the Stratosphere hotel — uses hydraulics to transport coaster trains up its initial hill and another hill that returns the train to its loading-unloading area. The entire attraction towers more than 900 ft above ground, so although it is not the fastest or steepest roller coaster, it certainly is the highest.

Most roller coasters use an electric motor, gearbox, and chain drive to pull a roller coaster up an initial hill. From there, the train coasts through the rest of the ride. The High Roller, however, has a metal fin protruding from the bottom of each train car. A hydraulic motor rotates a pair of counter-rotating wheels that acts as pinch rollers. So when the fin passes between the wheels, they propel the coaster train forward.

Prime directive for hydraulics

In every production of Star Trek — from the TV series in the 1960s to the most recent motion picture — the crew of the Enterprise must follow the prime directive of not interfering with the development of any civilization they encounter. Likewise, an unspoken prime directive for Star Trek: The Experience, at the Las Vegas Hilton hotel, is that none of the backstage equipment can make visitors aware of its presence. For this reason, motion must be precisely executed and controlled to feel natural instead of mechanical. Just as important, visitors should not hear any noise from pumps, motors, or other components, which would remind them that they haven't really been whisked into the 24th century.

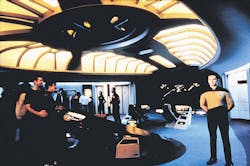

In Star Trek: The Experience, visitors stroll through the History of the Future Museum at their leisure, then enter a pre-show area where they are told about a ride they will be experiencing. As they enter what appears to be a loading area for the ride, they suddenly find themselves in the dark with wind blowing all around. Within seconds, the lights come back on, and they now appear to be in the transporter room of the Starship Enterprise.

Next, they travel to the the bridge of the Enterprise, where Commander Riker from Star Trek: The Next Generation explains from the view screen that they have been transported to the 24th century. He reveals that hostile forces will prevent visitors from being transported back to Las Vegas, so they instead have to take a shuttle craft to return to 20th-century Las Vegas.

Visitors then enter a turbo lift, which seems to take them to a different level of the Enterprise, the ship's Grand Corridor — which was never shown in any of Star Trek movies or TV shows. Finally, visitors enter what looks like a shuttle craft, but it actually is a replica mounted on a 6-axis motion base. This is where they get a prolonged feeling of travelling through time and space as they elude simulated enemies and eventually return safely to the Las Vegas Hilton.

Hydraulics does the trick

The transporter room, turbo lift, and shuttle craft all rely on hydraulics to produce realistic special effects. According to Jeff Borba, department manager of engineering at Star Trek: The Experience, Las Vegas Hilton, The transporter room works as an inverse elevator. Instead of moving occupants to a different location, the occupants remain stationary and a new location moves to them. This occurs in two stages. First, the assembly of four walls surrounding occupants of the loading area is raised 13 ft in less than 3 sec. Once this occurs, the ceiling moves horizontally 22 ft in 2½ sec.When the lights come back on, visitors now see the bottom half of the wall assembly, which looks like the transporter room. Likewise, they now see a half of the ceiling that looks very different from the one they saw when they entered the room.

The upper half of the wall assembly is now 13-ft above them, but they can't see it because of the ceiling. Also, the half of the ceiling they first saw is now 22-ft away, obscured by the "new" walls. The 7000-lb wall assembly was raised by a hydraulic cylinder with 78-in. stroke. A cable-and-pulley assembly doubles the cylinder's effective stroke (and speed) to quickly raise the wall assembly to its final height.

The 3000-lb ceiling, on the other hand, is powered by a bent-axis piston motor. This motor drives a Ford 9-in. differential (the same differential used in trucks and industrial vehicles) to evenly distribute rotational power to a pair of high-strength belt-and-pulley assemblies that slides the ceiling into a slot in the middle of the wall assembly.

Clearance between the ceiling and wall assemblies is only 1-1Ú8 in., so moving these massive loads so quickly requires extremely precise timing and motion control. Hydraulics provides the high power for rapid acceleration and deceleration, while electronics ensure sequential accuracy and tight position control.

After going through the illusion of being beamed into the 24th century, guests are instructed to enter a turbo lift to start them on a quick escape. The turbo lift is a cylindrical chamber mounted vertically with a door on its side. After guests enter though the door, the turbo lift pivots on three 2½-in. stroke cylinders that present the illusion that the turbo lift is moving. At the same time, the turbo lift slowly rotates at approximately 1 rpm about its vertical axis.

When the turbo lift stops moving, visitors exit through the door and enter a new room on the same level as the one they just left. The ride in the turbo lift gives the impression of transporting visitors to a different level, but it actually is just a chamber joining two rooms on the same level.

Ken Griffin, Technician at Star Trek: The Experience, Las Vegas Hilton, says this HPU has a 200-gal reservoir with an off-line filtration (kidney) loop. The kidney loop is driven by a 5-gpm gear pump piggybacked to the main pump. Fluid is routed through 3-µm filters and a 2½-gal heat exchanger for cooling. A pair of 20-gal accumulators provides supplemental flow for short-duration peak demand periods. A 25-hp electric motor running at 1800 rpm drives a main, axial-piston pump, which is pressure-compensated at 1500 psi to deliver up to 25 gpm. The pump is driven by a 25-hp electric motor running at 1800 rpm.

Hydraulic time-space continuum

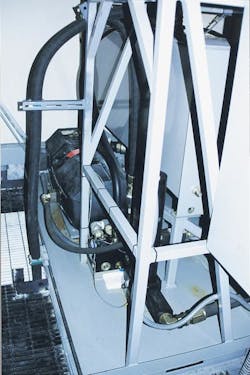

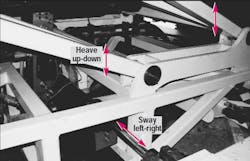

Visitors eventually make their way to a ride simulator that is a replica of a Star Trek shuttle craft mounted onto a 6-axis motion base. The motion base consists of three pairs of hydraulic cylinders mounted in a tripod configuration to provide six axes of motion — roll, pitch, yaw, surge (forward and back), heave (up and down), and sway (left and right). This tripod arrangement has become the standard for high-performance motion bases.

Hydraulic power for each of the attraction's four motion bases is supplied by a pair of Vickers 50-hp Integrated Motor Pumps. These pumps run quieter than conventional configurations, where the electric motor, hydraulic pump, and shaft coupling can transmit noise directly to the surrounding atmosphere.

High-tech effects bring legend to life

Early in our formal education, and even before, we are taught about our five senses. Not included in this mix are senses of motion and depth, which are integrations of sight, touch, and hearing. By stimulating these three senses, sophisticated motion simulators can create virtual experiences where participants can feel as if they have visited places that don't exist.

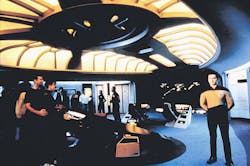

Such a place is the mythical city of Atlantis, which, legend has it, lies somewhere deep under the ocean. To bring this legend into modern times, the Caesar's Palace Hotel opened Race for Atlantis in January 1998. This is the first permanent attraction to incorporate a motion base with a large-format IMAX 3-D film. The 82-ft diameter IMAX Dome screen is the largest ever built for an attraction, and the four 27-passenger motion bases nestled within the dome can accommodate more than 1000 visitors per hour.

But that's not all. Multi-directional sound is generated by a 6-channel, 16-kW sound system, with an additional two channels transmitted by wireless Personal Sound Environment headsets worn by visitors. Another effect is provided by the world's largest water-based fog-generating system, which recovers and recycles the water to minimize consumption.

To provide three-dimensional images, the visual program is filmed through an IMAX 3-D camera and projected at 48 frames/sec. Left and right shutters on the projector cycle at 96 frames/sec to alternately display left or right images on the screen. Headsets worn by visitors contain LCD lenses that open and shut in synchronization with the images projected on the screen. So when the projector casts an image onto the screen from its right-hand lens, the LCD in front of the visitor's right eye is open and the one in front of the left eye is closed.

The headsets also contain left and right speakers to produce sound that is intended to be perceived as close by. Sound and LCD switching signals are transmitted to headsets through wireless infra-red transmitters.

Hydraulic-based motion

Each motion base provides six axes of motion through electrohydraulic cylinders controlled by servovalves and fitted with magnetostrictive linear displacement transducers for closed-loop position and motion control. As with the Star Trek attraction, motion bases have six cylinders arranged into a tripod configuration. In fact, motion bases for both the Atlantis and Star Trek attractions were designed and built by McFadden Systems, Santa Fe Springs, Calif.

Each cylinder is controlled by a servovalve mounted to it. This design configuration minimizes the amount of fluid between the servovalve and cylinder, which, in turn, maximizes system response by limiting fluid compliance between the servovalve and cylinder.

An accumulator serves each pair of cylinders to ensure that flow and pressure can be maintained by each cylinder. Accumulators also are relied upon by the hydraulic power unit (HPU) to store energy for peak flow demands. This allows using a smaller pump because the accumulators can be recharged during periods of low demand and release their stored energy when the system needs more flow than the pump can provide.

A third use of accumulators is for storing emergency power. Visitors board each motion base from a moveable loading/unloading platform. Before a ride sequence can begin, a pair of hydraulic cylinders pivots each loading platform out of the way. This prevents a collision from damaging the motion base or platform.

If, for example, an electrical power outage would occur, the HPU might not be able to power the cylinders into position to unload the motion bases. To prevent this from happening, hydraulic circuits for the platforms contain accumulators to store enough energy to fully actuate the cylinders, even if a complete electrical power outage occurs.

Application challenges

One of the challenges for the motion program, according to Brian Robison, general manager of Race for Atlantis, was the wide range of effects. For example, because some of the simulated adventure takes place in water, much of the motion has to give visitors the sensation of floating. This means when motion changes from up to down, and vise versa, there cannot be any jerking or stick-slip operation in the transition between directional changes. At other times, the motion base must behave like a chariot racing down a cobblestone street. This calls for sharp jolts and a rumble of wheels against the road surface.

Robison cited control signal management as another challenge. The main program takes up 1716 GB of hard drive space. The projector itself, with a pair of 15-kW, water-cooled xenon arc lamps, requires its own computer to monitor operation and generate the cues for the headsets, motion bases, safety systems, and other subsystems.

Search leads to simple solution

One of the tradeoffs often considered for motion base applications is how much motion is actually required. After all, if a visual presentation is large enough to encompass a viewer's entire field of vision, he or she will usually get a sense of motion even while standing on a stationary platform. Also, as motion bases incorporate more axes of motion, more complicated and sophisticate control equipment is needed to keep a motion sequence in synchronization not only with the visual presentation, but with itself. For instance, a 6-axis motion base arranged in a tripod configuration requires all six cylinders to move in close synchronization with each other, even for simple movements.

If motion is not in sync with the visual program, participants may experience motion sickness or become aware of the control error. In either case, visitors to such an attraction may leave unsatisfied. If motion of individual cylinders is out of sync, not only will the quality of the motion suffer, but the out-of-balance forces can apply excessive stresses to the motion base chassis.

In contrast to the motion bases for Star Trek and Atlantis, In Search of the Obelisk use only three axes of motion surge (34 in.), heave (18 in.), and sway (34 in.). John Lichtsteiner, technical manager, rides and attractions at the Luxor, explained that controlling only three axes of motion is much less complicated than controlling six. Furthermore, because each axis actuates independently, control programs are simpler.

For example, to execute a horizontal movement (sway) with a 6-axis motion base configured in a tripod arrangement, piston rods on all six cylinders would have to move. Some would extend, some would retract, and not all would stroke at the same speed. With a 3-axis base configured for linear motion, movement in any single axis requires only one cylinder to actuate. So the same horizontal move would require only the sway cylinder to actuate.

Lichtsteiner also explained that using only three axes of motion does not necessarily reduce the quality of perceived motion. He said the roll axis can be experienced simply by having the visual image pivot one way while the motion base moves horizontally in sync with it. He added that with linear motions, all riders experience the same movement. If a 6-axis motion platform rolls to the right, visitors near the center of the platform will simply tilt, whereas those near the perimeter will tilt and mover vertically. With linear motions, all visitors experience the same sensations no matter where they are seated.