Troubleshooting Challenge: Pump Keeps Losing Its Prime

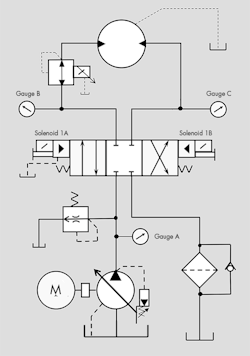

A land based oil-drilling rig used a large hydraulic unit (HPU) and motor to power its top drive unit for the drill pipe. The pump-motor and valve manifold was mounted on top of a 200-gal reservoir.

The crew was having problems with the pump losing its prime every time they shut down for more than 15 to 30 min. The hydraulic technician could not find where air was getting into the pump, and one of the roughnecks told him that all it needed was a flapper-type check valve installed in the intake line. The worker was accustomed to mud system pumps that transfer mud from one tank to another, and those use flapper checks on the intake of the pumps.

The technician thought this would be a good fix, so he installed a flapper-type check valve in the pump’s suction line. He started the HPU and bled air from the system until it quieted down. The pump then compensated at 3,200 psi. However, when the technician shut the HPU unit down, to his surprise, the brass flapper check blew apart.

Why wouldn’t the hydraulic pump hold its prime, and why did the flapper check blow out?

Find the Solution

Think you know the answer to this month’s problem?

Submit your solution by emailing Mindy Timmer at [email protected]. All correct solutions submitted by April 3, 2015, will be entered into a random drawing for a $50 gift card. The winner will be notified, and his or her name will be printed in a future issue. Only one gift card will be awarded to any participant within a calendar year.

Congratulations to Craig Chmielewski, of Milwaukee, Wis., who won February’s Troubleshooting Challenge by having his answer drawn at random from those who correctly solved that month’s problem. A $50 gift card was sent to him.

Solution to last month's problem: Pump-housing Cracking

The paper mill that lost its new pump shortly after commissioning was at a loss as to what caused the problem. The internal components of the failed pump looked brand new. Only the shaft seal and housing were damaged.

When the mill called us for help, we asked if anyone inspected the case drain hose going back to the tank. When they called us back, they said they found several parts of the original pump lodged inside the hose, blocking the case drain back to tank. This allowed high pressure to build in the case, so the shaft seal blew out and the pump housing cracked.

About the Author

Robert Sheaf

President

Robert J. Sheaf Jr., is the founder and president of CFC Industrial Training, formerly Certified Fluid Consultants, part of CFC-Solar Inc. CFC-Solar provides technical training, consulting, and field services to any industry using fluid power technology.

Leaders relevant to this article: