Mighty Minis of Construction

Construction equipment requires lots of power for digging, breaking, hauling, and any other heavy-duty task at hand. But just because compact construction machines are smaller than their full-size counterparts doesn’t mean they can skimp on power. They still need plenty of force for digging, high torque for drilling, and enough power to work quickly.

Small and versatile

Toro’s Dingo tracked loaders share several design features common to full-size loaders and excavators. For example, Dingo TX-427 compact loaders have twin hydrostatic crawler drive circuits — each capable of delivering 16.9 gpm of hydraulic flow to each track wheel motor. They also have individual hydraulic pumps for work functions — 6 gpm for the loader arm and 11.4 gpm for auxiliary hydraulics. This provides up to 19 hp of hydraulic power for attachments requiring high flow, such as auger drives.

Another important design feature of Dingo loaders is the use manifold-mounted cartridge valves. The manifolds conserve space over line-mounted valves by incorporating multiple valve functions into a single unit. The cartridge valve units also reduce the amount of hose and tubing needed, thereby eliminating potential leak sources and further conserving space.

And as with full-size loaders and excavators, compact equipment has become more versatile for contractors by making it quicker and easier to change attachments. This is especially important for smaller contractors who cannot afford to purchase several specialized machines. Instead, by changing an excavator shovel for a concrete breaker, the contractor can use one machine for many different jobs.

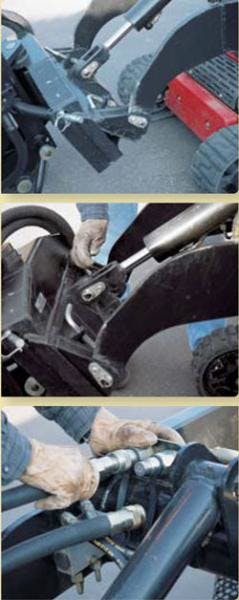

However, complicated attachment changeout may require operators with special skills and take excessive time. Toro avoids these potential drains on productivity with a simple, three-step attachment change procedure. An operator simply mounts a standard attachment plate to the TX-427, twists pins to lock the attachment in place, and connects quick-acting hydraulic couplings to the machine’s loader arms. The hydraulic couplings in the TX-427 have a flat-face design that prevents hydraulic oil leakage and also keeps contaminants out of the hydraulic system.

The attachments themselves have shielded seals to hold hydraulic leakage at bay and also prevent dirt, water, and other contaminants for entering the hydraulic system.

For more information on Toro’s Dingo line of compact loaders, visit www.toro.com/dingo, or email [email protected].