MICO Inc., North Mankato, Minn., a designer and manufacturer of hydraulic components, controls and brake systems, announced today that it has opened a new facility in Shakopee, Minn., to house its new Electrohydraulics (EH) group. The new group will focus on the growing market potential for electronic controls in combination with hydraulic brakes.

“As more and more of our traditional brake customers are requesting electrohydraulic systems, we have recognized how critical this trend is to the future of off-highway vehicle design,” said MICO EH Group director Manfred Maiers. “In addition to our expansion into complex innovations like regenerative braking, we’ll continue to enhance our existing electrohydraulic technology and provide the specific customer solutions for which we’re best known.”

The EH Group facility includes office, warehouse and laboratory space, allowing for on-site design, testing and verification. Manufacturing of MICO electrohydraulic components will continue to take place at the company’s headquarters in North Mankato, Minn.

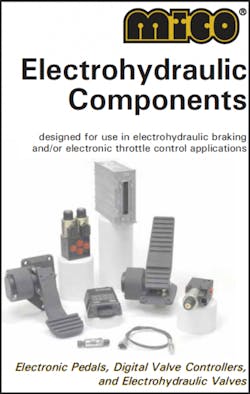

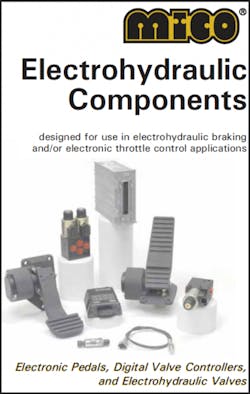

Visit www.mico.com for more details or click here to download a brochure on MICO's electrohydraulics line.

About the Author

Mary Gannon

Sr. Associate Editor

Leaders relevant to this article: