Recognizing the growing importance of testing and simulation to efficient component and machine design, Danfoss Power Solutions has partnered with Iowa State University to install a new off-road vehicle chassis dynamometer near the company’s Ames, Iowa location. This new application development center (ADC) will help drive testing and simulation efforts at Danfoss sites around the world.

“Comprehensive testing can reduce design cycles and speed up research and development, translating to saved time and money for our customers,” said Dave Wohlsdorf, senior director of strategic innovation for Danfoss.

At this premier site, partnering with Iowa State University will help the company expand its research and testing capabilities in North America. As the company adds new ADCs to its global network, engineers will work directly with customers to develop, test, prove, demonstrate, and refine a machine’s key systems.

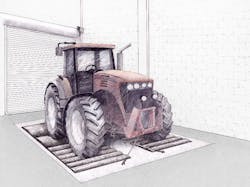

Along with the ADCs, the dynamometer will allow for controlled, dynamic testing of complete off-highway vehicles with advanced traction control systems. The Ames facility is designed to test vehicles up to 350 kW at 70 km/hr (470 hp at 43 mph), and will offer independent monitoring and loading of each wheel.

Ground will be broken for the Ames site on October 5, 2018, with completion targeted by summer 2019.

About the Author

Tom Andel

Tom Andel is an award-winning editorial content creator and manager with more than 35 years of industry experience. His writing spans several industrial disciplines, including power transmission, industrial controls, material handling & logistics, and supply chain management.

Leaders relevant to this article: