IDEA! Awards: Fluid Power Category Winners

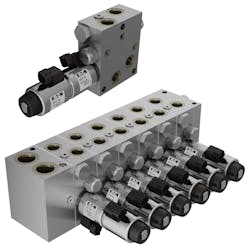

SLV20 Load-Sensing Proportional Directional Valve

Danfoss’s SLV20 load-sensing proportional valve is a priority flow-sharing solution for mini and micro machinery. Utilizing screw-in cartridge valves in aluminum sections, the SLV20 offers greater versatility and serviceability than cast iron valves, plus significant weight and space savings. A patent-pending multi-function logic element enables flow sharing and flow prioritization in the same valve bank, a feature previously available only on heavy traditional valves. Individual sections can be produced with additional functions, such as counterbalance valves, replacing remotely mounted ancillary valves. By reducing machine weight and providing flexible flow-control options, the SLV20 can increase efficiency, load-carrying capability and battery life.

MXT-XTP Hydraulic Hose

MXT-XTP is a hydraulic hose that combines patented wire braid technology that makes it lighter in weight and more flexible while maintaining 600,000 impulse cycle performance, which is three times the industry standard. The abrasion and ozone resistance XtraTuff cover provides additional protection for the hose to stand up to the toughest of applications. Ozone is everywhere and impacting hose performance, so having a robust cover material to prevent hose breakdown and keep machine uptime high is of great benefit. MXT-XTP joins the Gates lineup of other industry leading products that include MXG4K-XTP and Multi Master GMV.

Cartridge Flow Transmitter (CFT)

DGD Fluid Power enters the hydraulic market with the CFT (Cartridge Flow Transmitter) with multiple output options, providing a convenient digital solution to measure flows in hydraulic systems. The flow transmitter can be easily installed anywhere in the hydraulic circuit for continuous monitoring of all critical hydraulic functions, e.g., component performance, diagnostics, closed loop control and data acquisition for predictive maintenance and remote troubleshooting. Future models to be released include pressure and temperature sensors, combined with the CFT in a cartridge valve format.