Troubleshooting Challenge: Cable Pulling Winch Loses Power

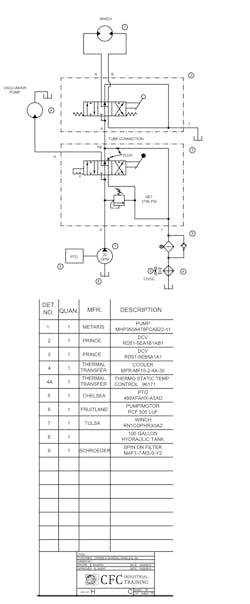

A customer was having problems with a winch and vacuum/air pump system on one of his pieces of cable pulling equipment. The winch valve did not have any power to pull the cable up on the reel, but the vacuum/air pump worked fine. The customer ordered a new winch valve and, after installation, found it did not cure the winch’s loss of power.

The pump circuit needed 1,800 psi, but the winch circuit only showed 250 psi maximum when trying to pull a cable. The only difference between the existing plumbing to the shown circuit was the winch valves tank line was connected before the filter, and only one valve function at a time was used. This should not have caused any problems because it had always worked before.

Any idea what the problem could be?

What’s the Problem?

Think you know the answer to this month’s troubleshooting problem? Then email your answer to [email protected]m (put “Sept” in the subject line.) All correct answers received by June 20, 2020 will be entered in a random drawing. The winner will be mentioned in a future column.

Solution to Last Month’s Problem

60-Ton Press Overheats When Idling

The overheating problem with the 60-ton press during idle was caused by the repair mechanic switching the location of the case drain checks. The ½ psi check was going directly to tank and not letting the case drain through the heat exchanger during idle periods. Switching their locations fixed the problem.

About the Author

Leaders relevant to this article: