A foundry casts 8-cylinder engine blocks then moves them through the machining department. After milling and drilling is complete, the blocks get transferred to a large automated washing, cleaning, and dryer machine.

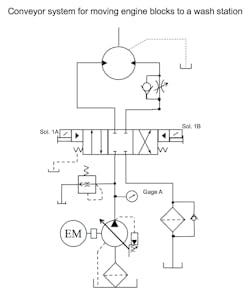

The foundry had replaced an old hydraulic power unit with a new one when it overhauled and upgraded the washer. The power unit company built, installed, and commissioned the new unit. It had a 45-gpm pressure-compensated piston pump rated at 1,000 psi with the same pilot-operated directional valve used on the older unit. The pump/motor was mounted on top of the reservoir, so an air bleed valve was added to help prime the pump. The original unit had an older directional valve with air gap solenoid; the replacement one had the newer wet armature solenoids. Everything was mounted on the reservoir in a neat compact arrangement.

The new pump failed after six weeks of running and was send back to the manufacturer for servicing under the warranty. The supplier denied the claim, saying the pump failed due to over pressurization. The original gauge was replaced, and a new pump installed and adjusted to 1,000 psi. Eight weeks later the pump failed again.

Any idea what the problem could be?

Find the Solution

Think you know the answer to this month’s troubleshooting problem? Then email your answer to [email protected] (put “Feb Troubleshooting” in the Subject line.) All correct answers received by June 20, 2020 will be entered in a random drawing. The winner will be mentioned in a future column.

Solution to last month’s problem

The accumulator prevents pressure dips when an actuator is energized. They work well if there is dwell time to keep it charged with oil.

The bag in the accumulator had failed and needed to be replaced.

Robert J. Sheaf Jr., is the founder and president of CFC Industrial Training, formerly Certified Fluid Consultants, part of CFC-Solar Inc. CFC-Solar provides technical training, consulting, and field services to any industry using fluid power technology.

About the Author

Robert Sheaf

President

Robert J. Sheaf Jr., is the founder and president of CFC Industrial Training, formerly Certified Fluid Consultants, part of CFC-Solar Inc. CFC-Solar provides technical training, consulting, and field services to any industry using fluid power technology.