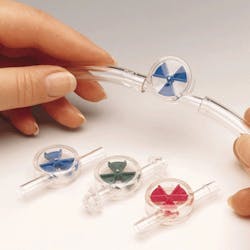

Indicators let you “eyeball” airflow

Bel-Art Products Inc., Wayne, N. J., offers an effective and economical solution: a series of in-line indicators that clearly shows users when differential pressure (therefore, flow) exists. Mounted in any position, the transparent-polystyrene indicator contains a wheel marked with blue, red, or green triangles. Whenever there is a change of pressure in the line, the wheel spins rapidly, yielding the appearance of a solid color. Each color corresponds to the indicator size and flow rating. Blue models fit and 1/4-in. tube and indicate flows from 0.5 to 10 lpm. Red models fit 1/4 and 5/16-in. tube and indicate flows from 0.5 to 10 lpm. Green models fit 5/16 to 1/2-in. tube. All three indicate flows from 0.5 to 10 lpm and are rated for pressure to 10 psig. Whenever pressure changes at either end of the tubing n the line, the wheel spins, yielding the appearance of a solid color.

For more information, call Bel-Art Products at (800) 423-5278 or visit bit.ly/17LilVD.