Manifold software simplifies design (web exclusive)

Comatrol, Easley, S.C., a member of Danfoss Power Solutions Group, has collaborated with Famic Technologies Inc., Montreal, a leading fluid power software simulation company, to make two new products available on its website — the second version of its hydraulic manifold circuit design software, EasyValve, and the first version of its valve catalog for Automation Studio software. Comatrol manufactures screw-in cartridge valves and hydraulic integrated circuits (HICs).

Built upon the Automation Studio Live technology, EasyValve 2.0 captures technical, commercial and application requirements to accurately document and communicate the custom HIC needs, allowing users to get exactly what they want from the first drawing, reducing the prototype cycle time by as much as half.

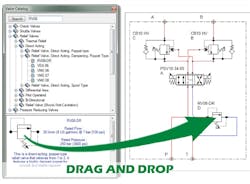

EasyValve’s interface allows a user to create a hydraulic circuit schematic by simply dragging and dropping from Comatrol’s digital library of cartridge valves, CETOP valves, and accessories. EasyValve 2.0 has several important improved features that are efficient and easy to use, including:

•quickly select and configure the products, ports and machining options needed,

•easy configuration with drop-down component selection functionality,

•assist users in making optimal technical vs. pricing decisions, with readily available information in the Component Specifications page of each item, including the valve catalog pages,

•capture user, technical, and HIC material information in the Project Information View,

•capture user-critical layout information in the Manifold Layout view, and

•outputs include a project file that stores all your work into one document [.HICS], a project summary, a schematic in DXF format and Automation Studio output [.HIX] to support user simulation needs.

Summary of features• Quickly select the products, ports and machining options you need by navigating the library, or by using the search function, then drag and drop onto your schematic layout. Outputs Include: Project Summary includes: |

According to Darren Magner, marketing manager at Comatrol, one of the main ideas behind the new software is simply to obtain more brand awareness by getting the free software into the hands of students at universities, distributors, and end-users. "EasyValve is the e-destination that takes custom HIC solutions to the next level by providing a streamlined development process from the customer to the Comatrol engineer. EasyValve’s intuitive user interface allows you to proficiently create your hydraulic circuit schematic by simply dragging and dropping from Comatrol’s complete digital library of cartridge valves, Cetop valves and accessories. Capture your technical, commercial and application requirements to accurately document and communicate your custom HIC needs — allowing you to get exactly what you want from the first drawing, reducing the prototype cycle time by as much as half.

“Users can do simulations with the software by putting it with a cylinder, motor, and other parts to see how it will work and operate,” Magner said. “After designing and simulating, they send to us, and we quickly make a 3D model. If it’s good, it’s ordered and sent to production, much quicker than before.”

Finally, more than 500 Comatrol components are included in the new Automation Studio catalog, also simplifying hydraulic system design. Users will be able to design hydraulic circuits faster and better by allowing them to create and validate — by functional simulation using Automation Studio — product performance and compatibility with other system components prior to block machining.

Visit www.comatrol.com/easyvalve for more information.

About the Author

Leaders relevant to this article: