The Old Timer of Royal Oak, Mich., was a regular contributor to H&P years before we ever even heard of the internet. But most of his advice is just as ueful — and interesting — today.

So rather than leave his wisdom printed on pages archived in our storage room, I pulled out issues from the late 1980s and early 1990s and have been reproducing relevant entries in this blog. Here is my tenth entry, which was originally published in the August 1988 issue

Strange things can happen in return lines

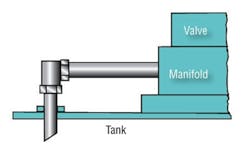

Tank or return lines often are the orphans of hydraulic design procedures. What can go wrong in a piece of pipe that only has to carry low-pressure fluid back to the reservoir? Here’s one story.

The reason: that valve operated the toggle-locking cylinder on a large-tonnage die casting machine. When the valve shifted to unlock the toggle, a momentary spring-snapping action accelerated fluid in the tank line to more than 120 ft/sec. Because kinetic energy is proportional to velocity squared, the eight-fold increase over design velocity resulted in an energy level 64 times higher. The weakest link in the return chain was the right-angle fitting and that was where we got consistent leakage and even some breakage.

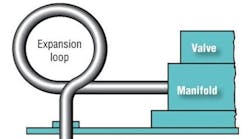

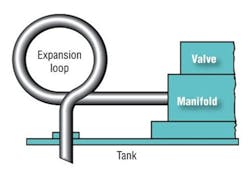

After half a dozen different standard fittings failed to solve this problem, we decided to take a page out of the French horn designer’s book and put in an expansion loop of tubing. It looked odd, but it halted our daily breakdowns. The loop lasted six months or longer.One of the foremen in the area decided that if one loop was good, more would be better. He got his best pipefitter and the biggest bend dies in the shop. They turned a length of tubing into a triple-loop pigtail that lasted for years on that die casting machine.