BOOK 2, CHAPTER 7: Why decompression is necessary in hydraulic systems

Why decompression is necessary in hydraulic systems

In high-pressure circuits with large-bore, long-stroke cylinders -- and the accompanying large pipes and/or hoses -- there is a good chance for system shock. In circuits with large components, when high-pressure oil rapidly discharges to tank, decompression shock results.

Decompression shock is one of the greatest causes of damage to piping, cylinders, and valves in hydraulically powered machines. The energy released during decompression breaks pipes, blows hoses, and can instantly displace cylinder seals. Damage from decompression shock may take time to show up because the energy released by a single shock may be small. After repeated shocks however, weaker parts in the circuit start to fail.

The potential for decompression shock is usually easy to determine beforehand and the design can be revised to avoid it. Shock from decompression normally occurs at the end of a pressing cycle when valves shift to stop pressing and retract the cylinder. The compressibility of the oil in the circuit, cylinder tube expansion, and the stretching of machine members -- all add to stored energy. The more energy stored, the worse the effects of decompression. Any time stored energy is a problem in a hydraulic system, a simple decompression circuit will add reliability and extend the system’s service life.

One type of decompression shock that is hard to overcome occurs when a cylinder builds tonnage, then breaks through the work. Because pressure is resistance to flow, once the resistance is removed, the oil expands and decompresses rapidly. Such is the case when punching holes in a part. Punching applications pose one of the worse shock conditions any hydraulic circuit meets. To help reduce this type shock, keep piping as short as possible and anchor it rigidly. Some manufacturers offer resisting cylinders that slow the working cylinder’s movement at breakthrough. These special cylinders may reduce or eliminate decompression shock.

Another type of shock occurs when oil flowing at high velocity comes to a sudden stop. This might happen when a cylinder bottoms out or when a directional valve shifts to a blocked condition. Whatever the cause, the effect is the same as trying to stop a solid mass moving at high speed. Use an accumulator or deceleration valve to control shock caused by a sudden flow stop. (See Chapter 1 on accumulators.)

The ensuing text describes applications where decompression shock might cause a problem. Also shown is the operation of some typical decompression circuits.

When using a decompression circuit, cycle time becomes longer. Instead of the cylinder immediately retracting after finishing its working stroke, there is a short delay while stored energy dissipates. (It may be possible to arrange to decrease cylinder traverse time to make up for decompression time.) In any case, the added cycle time, if necessary, will decrease down time and maintenance problems.

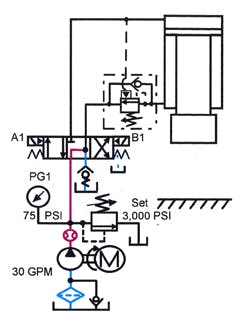

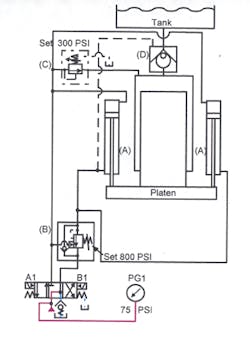

Press circuit without decompression

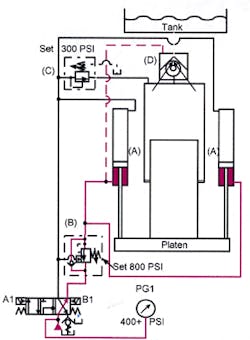

Figure 7-1 shows a schematic diagram for a typical medium- to large-bore cylinder without provision for decompression. A 50-in.-bore cylinder always needs a decompression circuit -- while cylinders with bores under 10 in. may get by without one. The main criteria are the volume and pressure of the stored fluid. The more high-pressure oil in a circuit, the greater the decompression shock. Long lengths of hose also cause and/or amplify decompression shock. It is best to install a decompression circuit when there is any chance it may be necessary. The expense of a decompression circuit is minimal and only adds to the cycle time if used.

The circuit in Figure 7-1 has a directional valve with an all-ports-open center condition. The pump unloads to tank when the valve shifts to this center condition. The cylinder stays retracted because there is a counterbalance valve on the rod port.

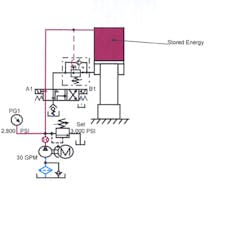

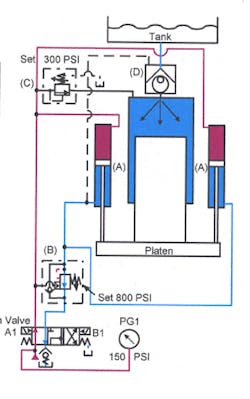

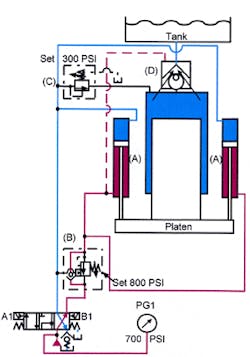

In Figure 7-2 the cylinder is pressing at a working pressure of 2800 psi. The 10-in. bore by 40-in. stroke cylinder holds approximately 3141 in.3 of oil. Added to this is another 800 in.3 of oil is in the pipe between the valve and the cylinder’s cap end. At a compressibility of approximately 1/2% per thousand psi, and allowing another 1/2% per thousand psi for physical expansion of the cylinder and pipe, plus frame stretch, total volume expansion could be up to 1% per thousand psi. Multiplying (0.01) X (2800 psi) X (3941 in.3) indicates that there are approximately 110 in.3 of extra oil in the cylinder when pressing at 2800 psi.

When the directional valve shifts to retract the cylinder, a large portion of the 110 in.3 of extra oil rapidly flows to tank. Every corner this fast moving fluid turns and every restriction it meets causes system shock. The shock only lasts a few milliseconds during each cycle but the damage accumulates. In a small system like this one, the shock may not be audible or give a noticeable jerk to the pipes. However each shock adds to the last one, and the damage eventually shows up in leaking fittings or broken machine members.

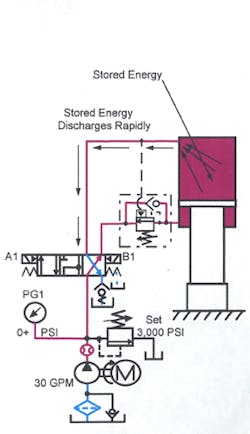

Press circuit with decompression

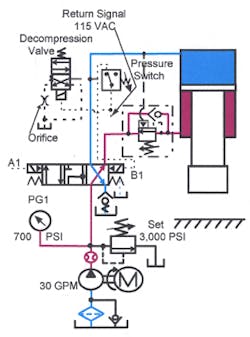

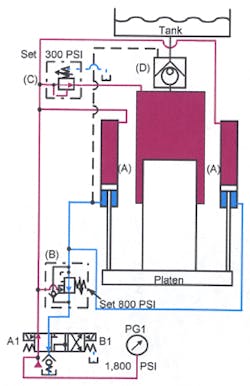

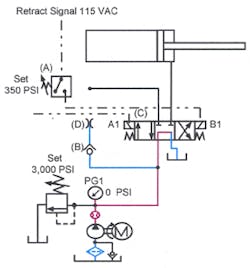

The circuit depicted in Figure 7-4 is the same as in Figures 7-1, 7-2, and 7-3, but a decompression circuit has been added. Also, the directional valve’s center condition has ports P, B, and T interconnected, while port A is blocked. A pressure switch and a single-solenoid directional valve (the decompression valve) are added to the basic circuit to make decompression automatic and adjustable. The cylinder is at full tonnage in Figure 7-4, ready for decompression before beginning to retract.

In this circuit, the signal to the retract solenoid on the directional valve passes through the normally closed contacts on the pressure switch. With a pressure switch setting of 350 psi, the retract solenoid will not be energized until pressure in the cap end of the cylinder lowers to that level and the contacts close. Set the shift pressure of the pressure switch high enough to shorten the decompression time as much as possible, yet still low enough to eliminate decompression shock.

In Figure 7-5, the extend solenoid on the directional valve has just been deenergized, and a 115-VAC signal to retract the cylinder is on, but is blocked at the pressure switch’s open contacts. The 115-VAC signal does go to the decompression valve’s solenoid and that valve shifts, opening a path to tank for any stored energy. Until pressure in the cap end of the cylinder deteriorates to the pressure switch setting, the cylinder sits still. The main flow of trapped oil in the cylinder is stopped at the directional valve’s blocked A port. This part of the cycle completely eliminates all shock damage -- although it does add to cycle time.

Note the orifice in the line going to tank from the decompression directional valve. A fixed or adjustable orifice works equally well here. The orifice size determines the length of decompression time. If the orifice is too large, shock is less but may still be enough to cause damage. If the orifice is too small, there is no shock but cycle time may slow.

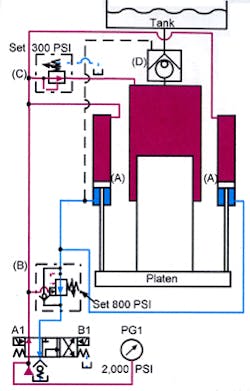

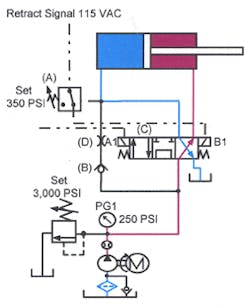

When pressure in the cylinder’s cap end drops to the pressure switch setting -- as in Figure 7-6 -- the pressure switch shifts to its normal condition. The normally closed contacts on the pressure switch pass a signal to the retract solenoid on the directional valve, and the cylinder retracts.

Large press circuit with prefill valve and decompression

On presses with large-bore cylinders or rams, oil compressibility is a problem. Another problem can be how to fill the ram as it approaches the work at high speeds and how to empty the ram when it retracts rapidly. The circuit in Figures 7-7 through 7--12 shows how to use a prefill valve to fill and empty a large ram. This type of prefill valve also can decompress the ram automatically without electrical controls.

Figure 7-7 shows the parts of a typical high-tonnage press. Small double-acting cylinders A (sometime called outriggers or pull-back cylinders) rapidly extend and retract the large ram. A small volume of oil cycles the outriggers for fast advance and return. Counterbalance valve B keeps the outriggers from running away and sequence valve C directs all fluid to the outriggers until the platen meets resistance. As the ram advances, vacuum opens prefill valve D, sucking fluid out of the tank to fill the large volume. Piloting the prefill valve open on retract first decompresses trapped oil, then allows free return flow to tank from the ram.

Figure 7-8 shows the cylinder extending toward the work. Pump flow to the outriggers A increases the rod-end pressure of these cylinders to open counterbalance valve B. When B opens, the platen starts forward and the ram pulls a vacuum in the cylinder tube. This vacuum sucks prefill valve D open and oil flows from the tank to fill the ram void. As the ram extends, the cylinder tube continues filling from the tank through D.

When the platen meets resistance, forward movement stops and pressure increases in the outrigger cylinders, Figure 7-9. When the ram stops, prefill valve D closes and pressure build-up opens sequence valve C, oil from the pump flows to the ram and outriggers simultaneously. The press can develop full tonnage during this part of the cycle. Ram speed during full tonnage is relatively slow because the pump flow is low in relation to ram volume. However, the horsepower requirement is at a minimum while the overall cycle is fast.

The outrigger cylinders must produce enough force while retracting to raise the platen and ram, as well as to discharge the volume of oil displaced by the ram. If the outriggers have a 2:1 rod-area ratio, use a regeneration circuit on the forward stroke for faster speed or add a small pump.

Replacing the sequence valve with a normally closed 2-way directional valve allows the use of a limit switch to tell the ram to slow before contacting the work. Also, using a bi-directional pump to control direction, speed, acceleration, and deceleration is common for large cylinders on presses or some other machines.

When the press completes its work stroke and reaches full tonnage, Figure 7-10, it is ready to retract. Pressure in the circuit is 2800 psi and the trapped oil contains a large amount of stored energy. To retract the press, deenergize the directional valve’s forward solenoid and energize its retract solenoid. The sequence valve closes when the directional valve shifts, and fluid in the cap ends of the outrigger cylinders flows to tank.

Figure 7-11 shows the press in decompression mode. Fluid from the pump flows to the outrigger cylinders’ rod ends and to the pilot port of the prefill valve. A prefill valve operates almost the same as a pilot-operated check valve. Pilot pressure opens the flow poppet for reverse flow when needed. However, on a prefill valve, the ratio of the pilot-piston area to the flow-poppet area is the reverse of a normal pilot-operated check. Most pilot-operated check valves have 3 to 4 times more pilot-piston area than flow-poppet area. On a prefill valve, the pilot-piston area is only about 1/10th of the flow-poppet area. This reverse area ratio keeps the flow poppet closed until most of the backpressure against it dissipates. Another feature of the prefill valve is that inside the main poppet of the prefill valve is a smaller poppet. The area of this small poppet is only 1/16th the area of the pilot piston, so it opens easily -- even with high pressure trapped inside the ram. The flow capability of the small poppet gives a quick, smooth decompression when it is piloted open.

As pressure builds on the rod sides of the outrigger cylinders, pressure in the pilot line to the prefill valve also increases. When pilot pressure is high enough to open the small poppet, decompression flow lowers pressure in the ram at a controlled rate. When ram pressure is low enough, pilot pressure opens the main prefill poppet. Low shifting pressure and flow of the inner poppet allows the prefill valve to meet most system requirements.

When the main prefill poppet opens, Figure 7-12, the ram freely retracts at high speed. Pump flow into the rod end volumes of the outrigger cylinders determines the ram’s retraction speed. The prefill valve allows fast ram movement in both directions of travel. This same prefill valve often has the option of automatic decompression as shown here. (Some manufacturers make prefill valves with large spools or sliding sleeves. They operate differently, but the end results are basically the same.)

Figures 7-13 through 7-16 depict a simple but effective decompression circuit for an application with a single valve and cylinder. There are no separate decompression valves to operate. This circuit can be adjustable and is easy to set up and maintain.

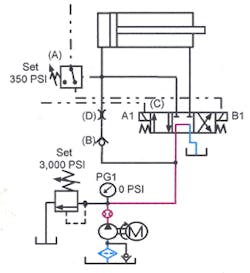

In Figure 7-13 the circuit is at rest. Pressure switch A keeps the directional valve from retracting the cylinder until a safe minimum pressure is reached. Check valve B blocks pump flow from the cylinder while retracting. Directional valve C unloads the pump, blocks main cylinder flow during decompression, and extends and retracts the cylinder. Adjustable or fixed orifice D controls decompression speed.

Figure 7-14 shows the cylinder meeting resistance and pressure increasing in the circuit.

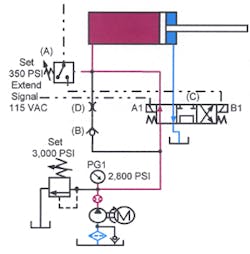

To retract the cylinder, Figure 7-15, the extend solenoid is deenergized and a retract signal goes to the normally closed contacts of pressure switch A. (These normally closed contacts are open at this time because pressure in the cylinder cap end is well above the 350-psi setting.) Directional valve C shifts to its center position; the pump unloads; and trapped fluid decompresses through orifice D and check valve B. The pump-to-tank condition of tandem-center directional valve C allows decompression flow while centered. Decompression lowers pressure in the cylinder cap end quickly, without shock, until pressure reaches the setting of pressure switch A.

When the contacts on the pressure switch close, they pass a signal to the retract solenoid on directional valve C. The valve shifts and the cylinder retracts as shown in Figure 7-16. This circuit requires no special electrical controls while eliminating decompression shock.

Another way to control the decompression portion of the cycle uses a time-delay relay. If the signal to retract comes from a time-on delay, set it for enough time to allow orifice D to decompress the cylinder before sending a retract signal to directional valve C. This type of control always gives an exact cycle time. Set the time long enough to make sure decompression takes place under any operating conditions. This usually makes the cycle longer than necessary, so it may not be a satisfactory arrangement for all machines.