Multi-element sealing system improves performance in high-load hydraulic applications: web exclusive

In hydraulic cylinders — used in everything from precise positioning equipment in machine tools to heavy earth moving machinery in the toughest working environments — the requirements for sealing are varied and difficult. The applications are dynamic, often operating at high speeds and significant pressures. A single seal is rarely a good enough solution and in most cases, a sealing system as a configuration of seals is required. For example, some solutions include U-cups with back pumping ability in combination with a double-acting scraper or step-seals in single or tandem configuration also in combination with a double-acting scraper.

One of the most important requirements for hydraulic seals is a long operating time without leakage. Seals with this property can reduce maintenance and repair costs. Without leakage they help to protect the environment. But performance requirements for hydraulic components increase continuously. Extended pressure, frequency, and speed rates lead standard sealing systems to a limit in terms of reliable performance. Additionally, more extreme temperatures and higher demands on chemical resistance complete the challenging demands for sealing systems.

In order to meet these requirements a new sealing system with a specific pressure between primary and secondary seal was developed.

Things to consider

One of the most important factors for the operating time of a sealing system is the lubrication condition in the contact zone between sealing element and counter surface.Interaction between the position of the pretension ring and the relief channel is essential for functionality. Different positions of the hole lead to different opening pressures, Figure 3.

Sealing reduces friction

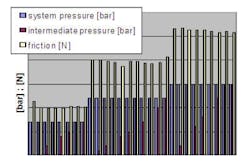

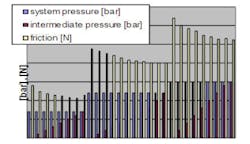

- System pressure: 7 / 12 / 15 MPa

- Intemediate pressure: 0 – 15 MPa

- Velocity: 2 mm/s

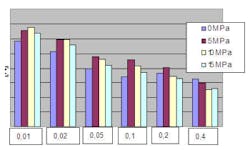

This means that the increasing load on the secondary seal with a direct related increase of friction force will be compensated by the improved lubrication and pressure balance of the primary seal. With an optimized choice of seal geometry and compound, the increase of friction in a sealing system due to intermediate pressure can not only be kept neutral but reduced.

The secondary seal is designed for a low increase of friction depending on pressure load so that the benefit of friction and balance on the primary seal is bigger than the increase of the special designed secondary seal. Figure 8 shows that the friction decreases considerably at higher speed and at higher intermediate pressure.

Lower wear means increased operating time

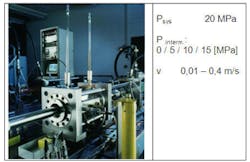

For the investigation of the wear behavior an endurance test rig was used, Figure 9. The following test parameters were used in the investigation:| • Pressure | p | 30 | [MPa] |

| • Temperature | T |

60 |

[°C] |

| • Stroke | s | 300 | [mm] |

| • Endurance | t | 250,000 | [cycle] |

| • Rod diameter | 50 | [mm] | |

| • Surface coating | chrome | ||

| • Medium | HLP 46 |

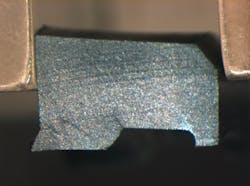

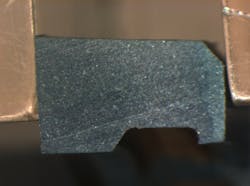

Without intermediate pressure the seal profile made of filled PTFE material shows typical deformation and extrusion for these test conditions, Figure 10, unlike the direct comparable test with intermediate pressure that shows significant better results, Figure 11.

Much lower wear and no extrusion at the primary seal leads to a significant increase of operating time.Because the intermediate pressure is limited to an allowed rate, the secondary seal also shows no wear.

Conclusion A sealing system with a pre-lubricated primary seal and integrated check valve in combination with an optimized secondary seal can improve the service time and reliable functionality of a sealing system by far.For more information, contact Holger Jordan, Manager Innovation Management, R&D Europe, Trelleborg Sealing Solutins, at [email protected] or visit www.tss.trelleborg.com.