Getting Connected to Sustainability

Flexible cables in energy chains and other applications are commonplace these days, but it’s important to realize their use in manufacturing is still young. Technology has advanced rapidly since the first cables were introduced in the late 1980s, and there were frequently issues with some early products.

In warehouse automated storage and retrieval systems, for instance, the pace picked up with the use of cables. Shutdowns, however, became frequent as cables became corkscrewed, which is an overload during the bending process that causes the cable to deform. It is caused by an incorrectly installed cable or a mismatched cable quality. The cable is adapted to the application and cannot withstand the load.

Especially with long travel distances and cables with many conductors, corkscrewing became common. Corkscrews are made for opening wine bottles and roller coaster lovers, not for manufacturers who need to get products out the door.

igus, the Germany-based manufacturer of high-performance plastics, has been one of the international leaders in solving the corkscrewing issues. And now cable use is growing. Statistics indicate the wire and cable market will reach $15.1 billion in the United States in 2022, an increase of 6% from 2021.

READ MORE: New Concepts Help Drive Popularity of New Machine Tool

One question that remains for the cable industry, however, is how to improve sustainability. Earlier this year, igus announced it had developed the first energy chain made from recycled material. However, cables have some inherent issues that prevent 100% recycling, at least for now. In the meantime, there are other ways that manufacturers can use cables to help meet sustainability objectives.

Start in the Beginning

Whether it’s reading a book, watching a movie or replaying the sports contest, it’s easy to jump ahead to the ending. With machine design, that’s a fatal flaw that is sure to lead to improper cable use – and a waste of money while also derailing sustainability objectives.

“We have had customers realize this and put a heavy emphasis on proper planning as well as installation,” said Tim Marran, igus’ Product Manager for chainflex cables. “This had led us to even offering a service where we will have certified technicians on site to do the cable and e-chain (cable carrier) installation work. That gives the customer peace of mind knowing that cable installation techniques, like cable placement in the neutral axis of an e-chain and strain relief, can be done properly.”

Cables start at less than $1 per foot, but a more expensive cable with added functionality might be a better choice. Manufacturers need to clearly identify how cables are going to be used to get the most out of them.

Once that determination is made, cable users need to be concerned with other aspects. Mistakes are frequently made with cable installation for moving applications using energy chains, including lack of interior separation, uneven weight distribution, improper strain relief and not installing cables along the neutral axis.

“Simple considerations in the beginning of the process can prevent issues such as loss of continuity, insulation damage, mechanical deformation or electromagnetic interference,’’ Marran said. “However, certain rules, such as filling only as much as 80% of a cable carrier’s cross section, have become outdated.”

Replacing cables every 6 months or year is highly inefficient. Manufacturers who design products and know precisely what they want the cable to achieve are in the best position to improve sustainability. igus offers a 36-month guarantee on its cables, which are tested extensively prior to coming to market.

“It’s important to be transparent about the best way to reach a long lifetime of the cable selected,’’ Marran said. “We have the testing and data to back it up. Every year we do research and development, and our testing process backs up our guarantee.”

Select the Most Efficient Cable

With respect to cable design, igus has been seeking to make the cables that are used in energy chain systems smaller. “This will help save space and weight inside the cable carrier system,’’ Marran said. “That will help with machine efficiency.”

Marran emphasized, however, that in some applications, larger cables might be more efficient. “This is where certain approvals or electrical characteristics would be beneficial to cut down on the number of parts and the amount of cable produced,’’ Marran said. “For instance, if insulation material increase would help gain the proper approval for 1000V instead of 600V, the overall cable outside diameter might be a bit larger. But that part number could be used in many more applications, considering it would be electrically applicable in more areas.”

He cited the example of an automated guided vehicle application that improved efficiency by simply swapping cables. “We were able to increase the lifetime of their cable by 10x, simply by selecting the cable for the specific motion they were seeing,’’ Marran said.

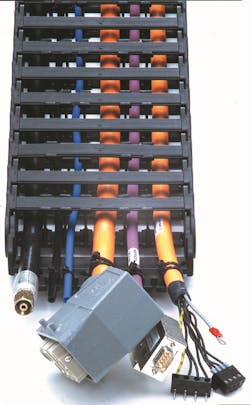

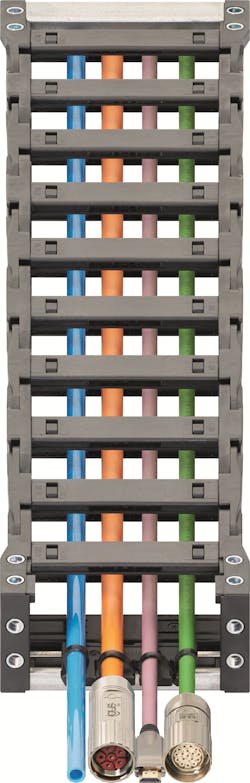

Quite a few decisions need to be made when choosing cables for energy chains. Cable diameter, interior separation, fitting rules and strain relief all figure into the equation. “Our energy chain systems can safely accommodate a wide variety of forms of data cables and energy suppliers in one system,’’ Marran said. “You have to separate the different medias.”

It is possible to mix pneumatics, electrical cables and hydraulics in the same compartments. But there also needs to be consideration of distances between certain cable types, like that of bus and motor cables. In addition to the quality of the cables used, the arrangement of each cable within the energy chain and the space allowed are important for the system’s service life.

Be Aware of Recycling Challenges

Cables can be hard to recycle. There are many different cable layers – copper conductors, insulation, inner jacketing, shielding, outer jacketing and center strain relieving elements – that complicate the recycling process.

“Cable recycling is more complicated than with energy chains,’’ Marran said. “It doesn’t mean it’s impossible. We have been recycling cuts of cable for many years now.”

Businesses can improve sustainability goals by purchasing the proper length. igus offers the ability to order customized lengths. Whether it’s 1, 100, 10,000 ft. or anything in between, customers can get the right cable with proper mechanical benefits.

“We already optimize the design of the cable, and with seven different jacket materials we can customize the cable part number solution to the specific application,’’ Marran said. “Customers aren’t wasting money on a cable they don’t need the mechanical benefits from but aren’t paying the smallest amount of money for a cable that won’t work and will require frequent replacement.”

The company did take one of the first steps this year in recycling initiatives with its first e-chain made from entirely recycled material.

The company has been collecting used energy chains from customers since 2019, so they do not end up in industrial waste. More than 32 tons of material have been collected across 13 countries since the program began.

“The focus should not be only on first use of products, but also the reuse of raw materials,’’ said Jörg Ottersbach, head of igus’ e-chains business unit. “We see a lot of ‘cradle-to-cradle’ potential and strive to reprocess as many raw materials and discarded products as possible so that precious resources are not wasted but used wisely for as long as possible.”

Utilize Predictive Maintenance Technology

Manufacturers can improve efficiency – both in cable performance and plant operation – with recently developed predictive maintenance systems. “Smart Plastics”, as igus calls it, allows customers to predict the lifetime of a product. The benefit is that manufacturers can see when equipment is reaching the end of its useful life. By replacing the component before it breaks, predictive maintenance also eliminates unplanned downtime.

“Smart Plastics isn’t just for our cables, but it also extends to e-chain parts, e-chain assemblies and other aspects as well,’’ Marran said. “I think it will be something more and more manufacturers focus on in the next 10 years.”

The company also provides a lifetime calculator and suggests other cables that might last even longer. “It might save the customer money if they aren’t looking for millions and millions of flex cycles,’’ Marran said.

Understand Environmental Commitments

While phrases such as sustainability, green energy and eco-friendly are now part of everyday conversation, that was not the case as recently as 30 years ago. Slowly, companies have come to realize they need to adapt sustainable practices to help protect the environment. Political discourse and a broadened appetite by consumers have accelerated change.

igus has taken its role seriously. Earlier this year, the company unveiled a bike made from recycled plastic. The company has stated its intentions to have its buildings and production be CO2 neutral by 2025. It reduced its CO2 emissions by 31% in 2021.

Recycled cables might not be on the market yet, but there was a time when bikes and energy chains were beyond recycling, too.

“The world is changing rapidly,’’ said igus CEO Frank Blase at the introduction of the bike made with recycled materials. “We want to shape change with innovative ideas. If, as with the igus bike, plastic becomes a valuable and sustainable resource, then the way we deal with plastic can also change positively in other areas.”

This article was written and contributed by Thomas Renner on behalf of igus. Renner writes on building, construction, engineering, and other trade industry topics for publications throughout the United States.

About the Author

Leaders relevant to this article: