Troubleshooting Challenge: Mill Removal Circuit Doesn’t Move for Large Rolls

This file type includes high-resolution graphics and schematics when applicable.

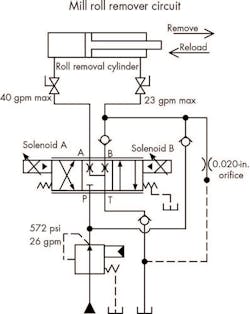

A temper mill had a roll-removal system that operated at the proper speed but had difficulty moving large rolls off the production line. A hydraulic cylinder extended to remove the roll and was controlled by a regenerative circuit to achieve fast, slowdown, and approach speeds. The regen circuit used a pilot-operated proportional valve; its pilot connection was fed by a pressure-reducing valve that limited pilot pressure to 572 psi. The pressure at the connection had been verified.

The system could move rolls weighing up to about half the rated capacity, but struggled with any rolls that were heavier. They checked the cylinder piston for leakage by shutting the cap-end ball valve while the cylinder was about half-way extended. Then they pressurized the rod end of the cylinder to see if it extended, which would indicate leaking piston seals. If it locked up, the seals were good. However, you have to leak all of the supplied flow across the piston for pressure to drop—a fact overlooked by many technicians.

The electrical maintenance technician was asked to examine the feedback signal to make sure the valve spool was responding, and it was according to the technician.

Any idea why the cylinder couldn’t move the heavy loads as intended?

Find the Solution

Think you know the answer to this month’s problem? Submit your solution by emailing Mindy Timmer at [email protected]. All correct solutions submitted by February 26, 2016, will be entered into a random drawing for a $50 gift card. The winner will be notified, and his or her name will be printed in a future issue. Only one gift card will be awarded to any participant within a calendar year.

Solution to last month’s problem:

Post-Hole Hammer Undergoes Pump Failures

The circuit was originally set up as a blocked center mobile type of directional valve with the power-beyond connection plugged. The machine owner was familiar with the power-beyond function and felt the pump did not need to compensate at 2,000 psi when idling. He had modified the power-beyond plug, essentially converting the valve to an open-center configuration. Therefore, the pump unloaded every time the directional valve’s spool centered in neutral position. This also made it easier to start the gas engine that drove the system.

Piston pumps need at least 200 to 250 psi of pressure when idling so oil can leak into the case to lubricate the many tight-fitted moving parts. The high idle speed exacerbated the problem. In my opinion, this design was not a good application for a piston pump.

About the Author

Robert Sheaf

President

Robert J. Sheaf Jr., is the founder and president of CFC Industrial Training, formerly Certified Fluid Consultants, part of CFC-Solar Inc. CFC-Solar provides technical training, consulting, and field services to any industry using fluid power technology.

Leaders relevant to this article: