There's nothing quite like a summer ride in the park, and several students are gearing up for a wild ride at the Cleveland Metroparks in Brecksville, Ohio, for the first-ever Parker Hannifin hydraulic bicycle competition.

Last September, Parker challenged its partner universities to come up with a useful and successful design of a human-and hydraulic-powered bicycle. Below are four of the nine designs student teams have developed.

Regenerative braking

At Cal Poly - San Luis Obispo, regenerative braking is the key technology the team is working on. Rather than applying brakes, this technique will use a break lever to operate a hydraulic motor. In turn, the hydraulic motor will charge an accumulator to provide energy.

The concept includes a pump or hydraulic cylinder that is hooked up to a crank. The cylinder pumps in both directions — when extending and extracting. The students also replaced the normal chain sprocket with a cam follower.

A piston pump will drive the hydraulic motor on the back of the bike, while the gear motor drives an internal 15-speed transmission for speed control.

Different teams, different styles

Students at University of Illinois have created two teams, each working with the same hydraulic technology but with different bike styles — upright and recumbent. These teams are using a simple system that does not include an accumulator. The system will have a geared input to a pump in the front and a direct closed link to a motor in the back. The students created renderings of the bikes on ProEngineer and are using standard frames for the actual bikes.

Sticking to the basics — Students at Murray State University are sticking to the basics with a simple hydraulic motor and pump. This system utilizes a hydraulic circuit, pump, accumulator, and gearing system. The rider will pedal the bike on the downhill, charging the accumulator for traveling uphill. This hydrostatic system will be fitted onto a three-wheel recumbent bike.

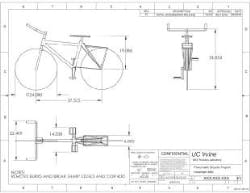

A pneumatic alternative — They're doing things a little differently at University of California, Irvine, where five students have opted to build a pneumatic-powered bike. Two 2-in. bore cylinders connected to the pedals generate pressure, while a 5-liter reinforced accumulator and 2.5 in. bore cylinder on the back turn the rear wheel. Solenoid valves, a microprocessor, and Hall-effect sensors were also included to time the air supply to the rear piston so the bike will move forward. A rear rack holds the bike's pistons, plumbing, and accumulator. The students chose a pneumatic system because it will keep the bike lighter than with a hydraulic systems, and it is environmentally friendly.

About the Author

Leaders relevant to this article: