Digitalization to be a Driving Force for the Future of Motion Control

Motion control components and systems continue to evolve to provide enhanced performance, efficiency and more. Digitalization is playing an important role in this by enabling more data collection and analysis for better condition monitoring as well as implementation of artificial intelligence (AI) to ease system setup.

In this interview with Power & Motion, Craig Nelson, Senior Product Marketing Manager at Siemens, discusses how digitalization and other trends are influencing current and future motion control designs.

Editor’s Note: Questions and responses have been edited for clarity.

Power & Motion (P&M): How does Siemens define motion control?

Craig Nelson (CN): We have a pretty broad definition of motion control [which] includes basically everything that is moving such as a fan, pump, roller, conveyor, [and] crane up to high-performance servo applications, robotics and high-speed production machines. Motion controllers we’re a little more specific when we talk about [those] such as a PLC (programmable logic controller). With these there is going to be some capability in it for positioning and typically doing coordinated motion control between multiple axes such as that required in a kinematic type of application or even a CNC (computer numerical control).

P&M: What new technologies or trends are you seeing impacting current motion control designs?

CN: In motion control, functional safety just continues to grow and be adapted to innovate the production floor on all levels including increasing productivity, efficiency, and, of course, safety. I still see this as the biggest bang for the buck on the motion control side.

Then there’s security; this is kind of the new kid on the block in motion control. Functions that you’re seeing added to our motion control and drives such as UMAC, that’s User Management and Access Control — assigning who has rights to do what — is securing data integrity, system integrity [and] that no unauthorized changes occur in your system. Along with network security for secure communications, these are all becoming topics that everybody’s eyes are open to. Figuring out how we’re going to harden our security defense, layer by layer, and the defense in-depth concept comes all the way down to the sensor-type components such as the drives.

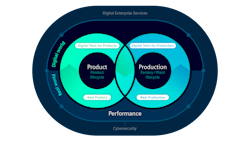

And then if you look at what’s new, rounding out the top three, you can’t leave out digitalization. This in itself is a huge topic for manufacturing with many new areas in it such as the digital drivetrain, real-time simulation, AI (artificial intelligence), condition monitoring systems (CMS) and how we get that information back to the edge and cloud, and all the connectors — that’s becoming a big thing with motion control. And this is going to give motion control a huge fingerprint in the whole digital twin lifecycle that we’re seeing.

P&M: Could you expand more on the digital twin lifecycle?

CN: This digital metaverse, or you may hear digital twin of your production facility or machine, that’s going to be a complete lifecycle starting the digital thread in the design stage and as you make [design] selections you have to ask ‘Is my selection right, can I use simulation now to prove that out before I build it and find out I built something wrong?’; [it will help] being able to right size everything and have flexibility to try new concepts on the fly.

Then the digital thread follows in the commissioning phase where we can simulate and prove out the programming before power up and on to production, being able to take data as its continuing to operate year after year, collecting that whether it be [on] an edge device or the cloud to do data analytics. This is what’s offering up so many new considerations that we’re looking at of how we improve everything — efficiency, productivity, using condition monitoring if something’s not operating as it was in the past [and] we quickly identify it. And we correct it as well, not just wait until 3 or 4 months later and end up in an unscheduled downtime situation. As an example, say a bearing was going bad and left unnoticed; we use a lot more energy and production may need to be scrapped, all effecting the bottom line. Being able to do a better job from concept to decommissioning with all this capability that we haven’t really had up to this point, I think that is going to be a big sea change and how manufacturing is looked at.

P&M: What are some of the challenges Siemens sees customers experiencing when it comes to implementing motion control systems, and how can these be addressed?

CN: The skills gap to adapt some of this new technology is really hampering its adoption in many organizations. To overcome this, we provide many canned solutions. And even inside those canned solutions we’ll have setup wizards that flatten the path to adoption. I’d say we’re on the forefront of using AI to help with everything from selection to programming to servicing of our motion control solutions.

P&M: Are you able to expand on how Siemens is using AI to do that, or is it still in the early stages?

CN: I would say it’s still in its early stages but we’re starting to see a lot of use case examples. The developing capability of AI is a little outside my wheelhouse, but I did see at Automate our keynote showed an example using AI to generate PLC code which everyone [was wondering] ‘Is that really happening, is AI really capable of that today?’ Imagine the resource savings if we could just program by saying add logic to E-stop, the VFD (variable frequency drive) using two fail safe outputs and the code is generated and tested within our program.

READ MORE about Siemens' keynote at Automate 2024 in the article "Standing-Room-Only Turnout at Tuesday’s Automate Keynote" from Machine Design, an Endeavor Business Media partner site.

P&M: How do you see motion control technologies and systems continuing to evolve in the coming years? Or what’s next technologically for these systems?

CN: Performance increases on everything [motion control products], so they’re able to run a lot more axes, they’re able to run a lot faster. But in general, the running of machines and equipment is going to become more autonomous, using AI is going to be a big part of it. You’re seeing a lot of mobile units in production now that we didn’t have even 5 years ago — the AGVs (automated guided vehicles), the AMRs (autonomous mobile robots). I saw an article on a BMW plant, they’re starting to integrate humanoid robots, so I think this is going to be real common within the next 5 years of having a lot more autonomous units that are going to be assisting production with minimum human interaction.

READ MORE: Mobile Robots to Remain Strong Segment of Automation Sector

That’s something we’re really going to have to take into consideration, how the motion control functions with a lot of these mobile units around and using motion control for these mobile units as well.

Collection and use of data to optimize everything; data analytics, increased productivity, [and] preventative downtime is a big thing here for efficiency levels because we’re going to have this looking glass into all these operations and all this data moving forward, this is going to really increase our sustainability as well because we’re going to be a lot more efficient and [have] a lot less waste.

One last topic is the impact software is having. I think that’s something that’s going to be a game changer from simulation to all the data collection — software is going to have a big influence on the production floor going forward and we’re trying to keep on the front end of that.

About the Author

Sara Jensen

Executive Editor, Power & Motion

Sara Jensen is executive editor of Power & Motion, directing expanded coverage into the modern fluid power space, as well as mechatronic and smart technologies. She has over 15 years of publishing experience. Prior to Power & Motion she spent 11 years with a trade publication for engineers of heavy-duty equipment, the last 3 of which were as the editor and brand lead. Over the course of her time in the B2B industry, Sara has gained an extensive knowledge of various heavy-duty equipment industries — including construction, agriculture, mining and on-road trucks —along with the systems and market trends which impact them such as fluid power and electronic motion control technologies.

You can follow Sara and Power & Motion via the following social media handles:

X (formerly Twitter): @TechnlgyEditor and @PowerMotionTech

LinkedIn: @SaraJensen and @Power&Motion

Facebook: @PowerMotionTech

Leaders relevant to this article: