Researchers Develop Color-Changing Sensor to Detect Mechanical Stress

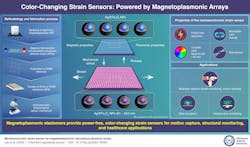

Researchers at Chungnam National University in South Korea have developed a power-free, color-changing strain sensor capable of detecting mechanical stress. The sensor is comprised of magnetic nanoparticles and elastic materials which enable it to detect stretching, bending, or pressure through a reversible color shift.

According to the research team, the strain sensor’s measurement capabilities enable it to be used in a range of applications such as wearable devices, structural monitoring and motion capture.

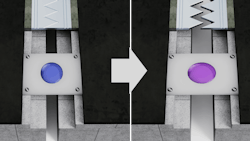

It also has the possibility of being used with hydraulic and pneumatic components. “When pneumatic or hydraulic pressure is applied, the sensor — attached to the surface of variable components — displays strain through distinct color changes corresponding to the degree of mechanical tensile deformation,” Professor Jaebeom Lee explained to Power & Motion. “For example, the sensor may appear blue at 20% strain, purple at 50%, and red at 100%, effectively reflecting the applied pressure or mechanical stress.”

By detecting stress on fluid power and other components or structures, potential performance issues can be addressed early before causing longer term maintenance issues and unplanned downtime.

How Researchers Created a Power-Free, Color-Changing Strain Sensor

The mechanochromic strain sensor developed by Professor Lee and his research team at Chungnam National University integrates flexible polymers with magnetoplasmonic nanoparticles (MagPlas NPs). These nanoparticles have a silver core (60 nm) and an iron oxide (Fe3O4) shell, which help them interact with light and magnetic fields.

A method called solvothermal synthesis is used to produce the nanoparticles. This method controls chemical reactions at high temperatures to create highly uniform particles in large quantities, enabling them to be synthesized with exceptional consistency and scalability according to Professor Lee.

Arrangement of the MagPlas NPs is a critical component of the strain sensor’s design. When a liquid droplet containing these particles is placed on a porous material, such as filter paper or a polyethersulfone (PES) membrane, and exposed to a magnetic field, the particles pack tightly together on the surface rather than seeping into the pores. This forms a uniform layer called an amorphous photonic array (APA), producing bright, consistent colors that remain stable when viewed from different angles.

The APAs are then transferred onto a flexible, stretchable material called polydimethylsiloxane (PDMS), which enables the sensor to change color under mechanical stress. Professor Lee said this substrate is made from silicone-based elastomers “that are chemically inert and thermally stable up to 300 C (572 F), and can withstand harsh environments such as high humidity or vacuum.”

Withstanding these environmental conditions enables the sensor to be used in a range of applications, including hydraulic and pneumatic systems.

Adjusting the nanoparticle size between 91 and 284 nanometers enabled the research team to control how the sensor’s color changed, with the most noticeable shift — from blue to red, occurring when the particles were 176 nanometers in size.

“These measurements are also reversible, meaning they can be repeated through cycles of stretching and shrinking,” said Professor Lee. This helps to create a durable and reliable sensor device.

The strain sensor developed by Professor Lee and his team can produce signals without the need to connect to a power grid, helping to reduce energy requirements — benefiting the desire of many to use ‘green’ and more sustainable technologies.

It also enables the sensor to be used in locations that have limited access to electricity or wiring. Not only does this help provide design flexibility by enabling the sensor to be used where most beneficial but also reduces the number of components required, minimizing design complexity and installation space.

Professor Lee and his team see the sensor benefiting a number of applications and industries due to its ability to detect movements, stress or damage. Results from their research were published in Volume 498 of Chemical Engineering Journal.

About the Author

Sara Jensen

Executive Editor, Power & Motion

Sara Jensen is executive editor of Power & Motion, directing expanded coverage into the modern fluid power space, as well as mechatronic and smart technologies. She has over 15 years of publishing experience. Prior to Power & Motion she spent 11 years with a trade publication for engineers of heavy-duty equipment, the last 3 of which were as the editor and brand lead. Over the course of her time in the B2B industry, Sara has gained an extensive knowledge of various heavy-duty equipment industries — including construction, agriculture, mining and on-road trucks —along with the systems and market trends which impact them such as fluid power and electronic motion control technologies.

You can follow Sara and Power & Motion via the following social media handles:

X (formerly Twitter): @TechnlgyEditor and @PowerMotionTech

LinkedIn: @SaraJensen and @Power&Motion

Facebook: @PowerMotionTech

Leaders relevant to this article: