Advanced Chip Technology Enhances Lidar Sensor Capabilities

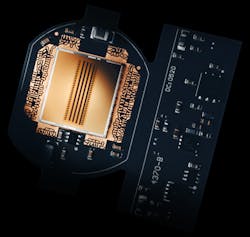

Ouster — a developer of digital lidar technology for use in autonomous vehicle systems, smart infrastructure, and other applications — has introduced a new chip that will be bring performance benefits to its sensor solution. The new L3 system-on-chip makes use of back-side-illumination, a method of arranging imaging elements to increase the amount of light captured to improve low-light performance. Made more widely accessible by the digital camera industry, Ouster is now bringing back-side-illumination to lidar sensors.

The company’s technology combines the various aspects of analog lidar onto a single silicon chip to help improve performance and system costs. This chip is integrated into Ouster’s various lidar sensors to enable visibility and range detection in a variety of use cases.

READ MORE about Ouster’s digital lidar technology in the article “Lidar Enters the Digital Age.”

The L3 brings “a step change capability improvement across our entire customer set,” said Angus Pacala, CEO of Ouster in an interview with Power & Motion. “We're bringing a really remarkable set of new capability to our existing product line, and it really will impact all customers.”

More Processing Power Improves Object Detection

The new L3 chip includes 125 million transistors and a maximum computational power of 21.47 GMACS which provides better digital signal processing and additional performance features for customers. With the chip’s improved on-chip processing capabilities, approximately 10 trillion photons per second can be processed and up to 5.2 million points per second produced.

Pacala said the new L3 chip is a long time coming as Ouster has been working on a new chip to utilize in all of its lidar devices. “This is like a decade jump in a single year for us,” he said regarding the technology advancements made with the chip. “It’s because we've been able to get access to a very advanced digital technology that allows our sensors to be 10 times more capable at collecting photons, collecting light, than ever before. And it’s unlocked some really great capabilities.”

With the improved light collecting capability, a longer detection range is possible said Pacala. “We can actually see two times further out in all directions and cover four times the area.” This is beneficial for an array of applications including surveying, drones, robotics as well as collision avoidance systems.

New Sensing Capabilities Now Possible

He said the new chip is also more precise and accurate due to its higher sensitivity. This enables millimeter precision measurements off objects in all directions. For customers who may have been using Ouster’s lidar technology for collision avoidance or navigation, they can now use the same device for surveying as well.

In an agricultural machine application, this could now allow for development of systems which look at features on plants to understand phenotyping (assessing a plant’s traits) or pick fruit out of a tree. Pacala said in construction applications, customers could use the enhanced sensor technology to create a survey-grade digital twin which is millimeter accurate while the machine onto which it is integrated is operating on the job site.

“It's unlocking new capabilities that our customers didn't expect would be capable with the sensors that they're already buying,” said Pacala. “I love that it’s delighting customers with capabilities they didn’t even know they needed in some cases or they weren’t buying lidar for in the first place.”

The fundamental goal of lidar as a sensing technology is to provide visibility as far away as possible with as much accuracy, precision and sharpness as possible. By now being able to provide a two times increase in those raw metrics is important for Ouster’s customers. “It's kind of like moving from SD video cameras to 4k video cameras and skipping HD in between, said Pacala. “It's a really big improvement in the underlying sensor technology.”

Ouster plans to use the L3 chip in all of its existing lidar sensor devices so customers will get the benefits of this new chip technology in all of the products available from the company.

Enhanced Lidar Sensors Coming to Market

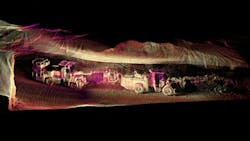

In conjunction with the launch of its new chip technology, Ouster will also be introducing its latest scanning sensor, the REV7. With the L3 chip, Ouster’s new REV7 will provide improved mapping capabilities, more accurate obstacle detection and safer autonomous operation in both indoor and outdoor environments the company said in its press release announcing the launch of the L3 chip and REV7 sensor.

The REV7 is comprised of approximately 95% automotive-grade components which helps to ensure its durability in a range of applications. Upgrades to the sensors improve maximum operating temperature, reduce power draw, and double the sensor’s resistance to shock and vibration without adding weight.

Additional highlights Ouster points out about the new REV7 include:

- 10x increase in photon sensitivity due to L3 chip

- 2x range increase across all sensors, up to 200 m at 10% reflectivity

- maximum range over 450 m, helping track objects beyond a quarter mile in all directions

- high resolution for short-, mid-, and long-range applications

- increase in maximum operating temperature by 10 C

- 1000Base-T1 automotive ethernet now available.

The 10x signal improvement provided by the new L3 chip enables the REV7 to better detect objects not only at a further distance but also those closest to the vehicle into which the sensor is integrated. Ouster said this will enable many customers to better detect challenging objects such as tires, black cars, cables, fencing or forks on a forklift. This capability will also benefit the enhanced mapping capabilities of the new sensor.

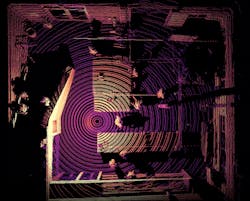

For industrial and smart infrastructure applications, Ouster is introducing its new OSDome sensor as part of the REV7 product family. It also makes use of the L3 chip to provide a hemispheric field-of-view with zero blind spots. The sensor has a small form factor which can be discreetly installed into the body of a vehicle or ceiling of a building.

Features of the new OSDome sensor include:

- hemispherical 180-degree field of view eliminates blind spots for floor-to-ceiling coverage

- 128 channels of vertical resolution

- 20 m range (10% reflectivity) for wide area coverage

- high-precision dual returns for enhanced object detection

- privacy-safe, accurate people tracking.

The sensor’s floor-to-ceiling vertical visibility will benefit use in autonomous mobile robots (AMRs) in warehouses which Ouster said have historically struggled to detect objects directly below or overhead. This will help to improve safety and overall operation of the AMRs.

READ MORE: Autonomous Mobile Robots on an Upward Trajectory

In smart infrastructure applications, the OSDome can augment or replace CCTV and thermal cameras. Its ability to cover a wide area with accurate 3D object classification and tracking will benefit a variety of use cases in this area said Ouster.

The company’s newest sensors and L3 chip are available to order and the first units are expected to ship in the fourth quarter of 2022.

About the Author

Sara Jensen

Executive Editor, Power & Motion

Sara Jensen is executive editor of Power & Motion, directing expanded coverage into the modern fluid power space, as well as mechatronic and smart technologies. She has over 15 years of publishing experience. Prior to Power & Motion she spent 11 years with a trade publication for engineers of heavy-duty equipment, the last 3 of which were as the editor and brand lead. Over the course of her time in the B2B industry, Sara has gained an extensive knowledge of various heavy-duty equipment industries — including construction, agriculture, mining and on-road trucks —along with the systems and market trends which impact them such as fluid power and electronic motion control technologies.

You can follow Sara and Power & Motion via the following social media handles:

X (formerly Twitter): @TechnlgyEditor and @PowerMotionTech

LinkedIn: @SaraJensen and @Power&Motion

Facebook: @PowerMotionTech

Leaders relevant to this article: