Troubleshooting Challenge: Compactor Return-Line Filter Problem

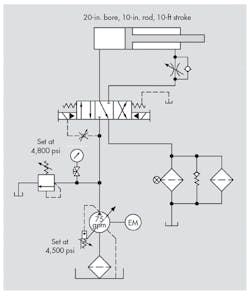

A large cardboard baler at a paper mill started blowing return filter elements off of the filter housing. The baler chamber would start off with little cardboard in it, then the large baler cylinder would extend until cardboard was compressed enough to cause hydraulic pressure to reach 4,500 psi. The piston rod would then retract based on pressure, not stroke position, for the next cycle.

The return-line filter assembly (consisting of two elements) would start leaking around the seal at the top of the element. Then one or both elements would blow off. This was not a new machine and worked well for several years.

Oil samples were failing the ISO cleanliness code required for a 4,500-psi system and were determined to be the cause of several cylinder failures. Consequently, maintenance technicians had recently changed the filter elements to a Beta 10 = 100 from the original design of Beta 10 = 15. This was suggested by a vendor they used for hydraulic systems. The original filter assembly was rated at a maximum flow of 135 gpm and 150 psi with a bypass check set at 50 psi.

Any idea what the problem was and how to fix it?

Find the Solution

Think you know the answer to this month’s problem?

Solution to Last Month's Problem:

Hydrostatic Side Thruster Stops Working

The hydrostatic side thruster pump was not stroking to provide enough flow to the thruster motor. Without charge pressure, the pump control could not stroke the pump.

We removed the charge pressure pump and found the drive shaft tang had sheared off. Replacing the charge pump fixed the lack of charge pressure and the thruster then worked. However, we could not find anything that could have caused the tang to fail. This failure would be caused by over pressurization and the charge pump relief and two check valves seemed to function fine.