Electrohydrostatic Actuation Captures the Best of Hydraulic and Electromechanical

Hydraulic actuation has existed for a long time and continues to provide the power density required of many applications. But in recent years there has been a push toward electromechanical actuation options because they are considered to be more energy efficient and there are no issues with oil leakage – but this technology has its drawbacks as well.

Electrohydrostatic actuation, on the other hand, brings together the best of both technologies said Dave Geiger, Engineering Manager, New Business Capture at Moog Inc. “It offers you all the benefits that electromechanical [provides and] it also offers you all the benefits of hydraulic actuation.”

While more costly than electromechanical options, he said that if you need to capture the best of both worlds, electrohydrostatic is your best choice.

Electrohydrostatic Actuation Ticks all the Design Boxes

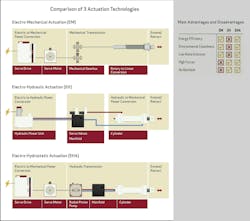

Geiger explained that electrohydrostatic actuation technology works similarly to electromechanical actuation in that a bidirectional motor controls the linear or rotary motion of the output device (i.e., an actuator). The difference is that electrohydrostatic technology uses a hydraulic transmission to transfer motion versus a mechanical transmission.

“So, it's a hydraulic transmission between the output of the actuator and the motor itself,” he said.

Compared to purely hydraulic or electromechanical actuation, Geiger said electrohydrostatic technology ticks all the boxes in the five main categories designers grapple with when developing motion control systems:

- energy efficiency

- environmental cleanliness

- low noise emissions

- high forces and

- zero backlash.

Hydraulics are not known for being particularly energy efficient – though there is a lot of development effort in this area currently – and the potential for oil leaks tends to negate their environmental cleanliness. They are also noisy, but again there are developments in progress to reduce their noise levels. But hydraulics are very good at providing high forces and do not create backlash which is not a good thing to have when trying to create precise motion control, said Geiger.

The shift to electromechanical systems came about because hydraulics are lacking in the first three categories, especially energy efficiency and environmental cleanliness which have become more important factors today than they were in the past. While electromechanical actuation offers the benefits of energy efficiency, low noise emissions and environmental cleanliness, this technology lacks the ability to provide high forces and not have backlash in the system.

Geiger said this is where electrohydrostatic comes in because it performs well in all five categories as it brings the beneficial aspects of electromechanical technology together with those of hydraulics.

READ MORE - Electrohydrostatic Actuation: An Energy-Efficient Option

How to Choose the Right Actuation Method

Understanding your cost parameters and application requirements are key factors to consider when determining which type of actuation technology to use.

Hydraulic vs. Electromechanical Actuation

The goal of hydraulic and electromechanical actuation is the same, but how each occurs is where they differ.

For hydraulic actuation, a proportional valve controls the rotary or linear motion of the output device. The problem with this technology said Geiger is it is not efficient due to the tremendous amount of pressure drops which occur across the valve and thus consumes a lot of energy.

Electromechanical actuation, on the other hand, uses a bidirectional motor to control motion. The motor moves the output device of the actuator forward and back by changing the speed and the direction of that motor, he explained. And typically, a mechanical transmission is used such as a gearbox for rotary motion or a screw for linear motion. However, this technology is limited when it comes to force output and durability.

For those who are cost conscious and are less concerned with energy efficiency and environmental impacts, then hydraulics are the route to go. “It is still the lowest cost [option] on the market…[and] it is the most readily available solution, there is so much product out there you can choose from,” said Geiger.

If cost is still a factor as well as energy efficiency and the environment, then an electromechanical actuation system is likely the best fit.

Electrohydrostatic actuation comes into play when energy efficiency and the environment are important to an application, but an electromechanical device will not meet its high force and durability requirements.

“For electrohydrostatic, when the customer is really concerned about the environment and energy efficiency but can't make it work with an electromechanical solution, that's where the electrohydrostatic [solutions] come in,” said Geiger.

“And typically, the reason [the customer cannot] make it work is because it is in an application that requires extremely high forces, or extremely high durability requirements [because] there's maybe a lot of shock loading on the actuator. And then that's where we would say we need to go into an electrohydrostatic application; that is where it is really best suited.”

Geiger said Moog takes a technology neutral approach when working with customers as it offers all three actuation technologies and believes in recommending the best option for the application.

Market Adoption Continues to Grow for Electrohydrostatics

Electrohydrostatic actuation has been proving itself in various industries for many years, and continues to gain market share in those looking for a combination of high forces, energy efficiency and reduced environmental impact.

Geiger said Moog has been using the technology since the 1980s when the aircraft industry wanted to move to fly-by-wire – essentially running wires from where the actuation is happening – for its flight controls. Historically, hydraulic systems were used but the industry wanted to eliminate all the hydraulic lines involved due to their potential to leak and the efficiency gains possible by having fewer lines through which to transfer energy.

Electromechanical was not an option because while the required forces are low, the industry did not want there to be any risk of primary flight controls failing. He explained they wanted a by-wire (essentially an electric) solution but did not want mechanical devices such as screws or gearboxes to be part of it due to their potential to fail.

This left electrohydrostatic actuation as the option because from a transmission point of view, the technology works the same as a hydraulic system, said Geiger. “We [Moog] ended up moving that industry into electrohydrostatic for primary flight controls.”

Industrial machinery is another sector shifting away from hydraulic actuation technology, due in part to greater environmental pressures to reduce energy consumption and emissions. Geiger said the move from hydraulics to electromechanical or electrohydrostatic – depending on the force needs of the machine – started slowly but has picked up the pace in recent years. “Now there’s fairly quick movement,” he said.

Because of the energy efficiency and high force capabilities possible with electrohydrostatic actuation, he anticipates rapid movement toward the technology over the next 10 years in the industrial machinery sector.

READ MORE - Industrial Hydraulic Concept Offers Best of Both Worlds

Geiger also sees opportunity for the use of electrohydrostatic actuation in the mobile construction equipment market as it transitions to battery-electric power systems. Often considered to be a slow adopter of new technology, the construction machinery sector has increased development of battery-electric options over the past 5 years.

He said these machines require the use of highly efficient actuation to minimize energy drawn from the battery which could otherwise shorten its operating time between charges. There are examples of compact machines using electromechanical actuation, such as the Bobcat T7X all-electric compact track loader developed in collaboration with Moog Construction.

The challenge, however, is the larger size machines with higher force and durability requirements which cannot be met with currently available electromechanical technology. Electrohydrostatic actuation might be the right solution though for these machines because it can provide the high levels of force and efficiency required.

“I think that's the big future right now for electrohydrostatic because it's such a big market and that industry is changing,” said Geiger. “From a volume point of view and from a movement, I think that's going to be where we're going to see a lot of traction.”

He noted that other heavy-duty mobile machinery like agricultural machinery and mining equipment could also benefit from this technology. And if fuel cells become the power source of choice in the future, electrohydrostatic systems will prove beneficial in these applications as well.

As with any technology, cost is always a factor. Geiger said certain industries are very cost sensitive which can cause hesitation when moving to a different actuation technology.

Construction is one of these industries which he said is extremely cost sensitive. “That’s one of the reasons that industry has stuck with classic hydraulics for such a long time because it was so cheap.”

Cost pressures will be a huge challenge to overcome because electrohydrostatic systems are not cheap, said Geiger. But construction is an industry with high-volume potential “and we're hoping that through volume we can get those costs down,” he concluded.

Shifting Industry Knowledge Could Change Technology Needs

The generational shift taking place in many industries is an aspect which could benefit the uptake of electrohydrostatic technology. Geiger said students coming out of school today likely won’t have knowledge of hydraulics, unless in a fluid power program, but they will know how to design servo motor and electromechanical related technologies which will aid development and maintenance of these systems.

In industries such as construction there is a lot of familiarity with hydraulics because of the years of experience workers have had with the technology. That institutional knowledge is leaving though as older generations retire from the workforce which could make room for other technologies to enter the space.

The complexity of hydraulics has been a longstanding issue, as well, which alternatives could overcome. “If you take a look at how many valves and how many manifolds [are in a hydraulic system] it is such a complex circuit; if one thing goes wrong in that circuit, it is hard to figure out what is going wrong,” explained Geiger.

“Hydraulics is absolutely the most difficult to manage and design,” he said.

Electromechanical systems have fewer components and therefore it is easier to determine where an issue is occurring. Electrohydrostatic is similar in that sense, although it has the hydraulic transmission. But that transmission is distributed and simple he said, “because it resides on the actuation whereas in a normal hydraulic system, there's this massive manifold that feeds all these different actuators on the machine.”

Being a distributed system makes it easier to determine the location of a fault because it happens on the actuation instead of a central system controlling many actuation points, he explained. “Whenever you have a distributed system like that, it is a lot easier to troubleshoot.”

Geiger said electrohydrostatic systems may be a little more difficult to troubleshoot than electromechanical, but far easier than hydraulics.

About the Author

Sara Jensen

Executive Editor, Power & Motion

Sara Jensen is executive editor of Power & Motion, directing expanded coverage into the modern fluid power space, as well as mechatronic and smart technologies. She has over 15 years of publishing experience. Prior to Power & Motion she spent 11 years with a trade publication for engineers of heavy-duty equipment, the last 3 of which were as the editor and brand lead. Over the course of her time in the B2B industry, Sara has gained an extensive knowledge of various heavy-duty equipment industries — including construction, agriculture, mining and on-road trucks —along with the systems and market trends which impact them such as fluid power and electronic motion control technologies.

You can follow Sara and Power & Motion via the following social media handles:

X (formerly Twitter): @TechnlgyEditor and @PowerMotionTech

LinkedIn: @SaraJensen and @Power&Motion

Facebook: @PowerMotionTech

Leaders relevant to this article: