Valve building blocks

Spool-type valves are widely used because they can be shifted to two, three, or more positions for routing fluid between different combinations of inlet and outlet ports. They are used extensively for directional control of actuators because a single valve can produce extension, retraction, and neutral of a cylinder or forward, reverse, and neutral of a motor.

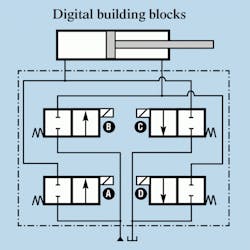

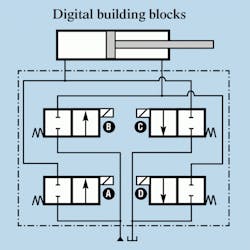

Energizing solenoid A routes pressurized fluid to the cap end of the cylinder, causing the rod to extend. Simultaneously energizing solenoid D routes fluid from the cylinder’s rod end to tank. In similar manner, energizing only solenoids B and C causes the rod to retract and routes fluid from the cylinder’s cap end to tank.

The valves in the figure at right are arranged to function as a 3-position closed-center spool valve. An open-center valve could be achieved simply by making all the digital valves normally open (NO) instead of normally closed. Likewise, tandem- and float-center configurations can be accomplished by using various combinations and placement of NO and NC digital valves.

An advantage of digital valves over spool valves is that digital valves use a poppet or plunger, so no cross-port leakage occurs. A limitation is that they cannot provide the proportional control of spool valves. However, acceleration and deceleration ramps can be achieved by using soft-shift valves.