PMP Industries, Coseano Udine, Italy has developed several technical solutions for hydraulic excavators that integrate a planetary gearbox with hydraulic axial piston motors. For example, the lifespan of a planetary gearbox is highly dependent upon torque spikes. During starting and braking phases, the inertia of the excavator causes pressure spikes — spikes that the single spool counterbalance valve typical of the application is unable to smooth effectively. Consequently, PMP engineers have developed travel drive integrated motors that smooth out pressure peaks, thereby increasing the life span of the vehicle’s transmission.

The key component of this drive is PMP’s Smoothness Valve. In conjunction with the counterbalance valve it acts as a damper, economizing the single spool counterbalance valve while preserving soft control of piloted motion control valves. The effect on the excavator is immediately felt by the operator, with greatly improved crawl stopping comfort. The smooth start-and-stop valve allows the parking brake to be completely released when axial-piston motors start to receive power. This feature increases efficiency and completely eliminates any possible friction disc wear. Used in tandem with PMP’s patented axial guide solution — a static counter plate of friction discs — it ensures a reliable braking torque all along the transmission lifespan.

Application engineers are able to tune the damper valve to specific application parameters, with the selection of the proper metering orifices that controls both speed and flow. The solution studied for the excavator has been successfully adapted to a wide range of different applications (e.g., crusher and drilling machines). On these types of machines the smoothening damper valve has allowed the design of extreme compact integrated transmission with an improved lifespan.

Other advances

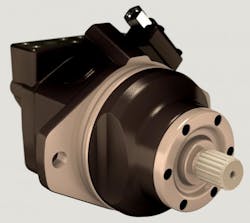

Heavy and slow machines typically sacrifice operator comfort for control of the machines’ high inertia. On faster machines such as excavators, an increase in comfort is strictly linked to increased gearbox lifespan. Experience with travel drive has led to the development of the new MKF series fixed-displacement axial-piston motors designed for use with PMP’s PMC transmission. The MKV series is also offered as a dual-displacement option. These motors are used especially on agricultural and forestry machine equipment, where a closed circuit system for traction is widely used.

The strong duty cycle and intensive use typical of these applications are the basis of the PMP heavy duty axial piston units’ success. The split of planetary gearbox from hydraulic motor allows the parking brake to ensure full braking torque without considering hydraulic braking. The hydraulic unit is compact and allows PMC transmission to withstand the machine and load weight together with high torque output.

Swinging into action

The swing drive is the heart of the excavator, because it must provide continuous operation for the entirety of the working shift. The PMP Swing drive range covers all construction machinery needs, as for travel drive open and closed circuit motors have been developed in order to match the different applications. Despite the circuit layout, swing motors withstand the most demanding duty cycle due to the inertia of the turret. Transitory speed ramps from zero to maximum and from maximum down to stop cover the majority of working time, and are carried out at maximum torque.

Component materials and heat treatments are crucial to allow the gearbox and motor to cover the correct lifespan. Nitrided surface treatment is used for crucial parts subjected to heavy wear, whereas traditional carburizing is used for high fatigue resistance.

Braking valves on open-loop motors are dedicated to turret inertia control. Soft braking is obtained thanks to two different features. One is the progressive increasing of relief setting pressure, which increases during braking and ensures ramped braking torque increase. The other compensates of pressure spikes switch and prevents the bucket vibration around stop position.

Alessandro Lanza is Chief Engineer of Fluid Power at PMP Industries, Coseano Udine, Italy. For more information, visit www.pmp-industries.com.

About the Author

Leaders relevant to this article: