The Old Timer of Royal Oak, Mich., was a regular contributor to H&P years before we ever even heard of the internet. But most of his advice is just as ueful — and interesting — today.

So rather than leave his wisdom printed on pages archived in our storage room, I pulled out issues from the late 1980s and early 1990s and will reproduce relevant entries in this blog. Here is my third entry, which was originally published in the June 1987 issue:

Maintenance tip: spotlights help solve high-low mystery

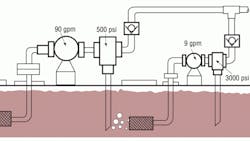

The equipment we received for a complex pressing operation included two reservoir-mounted pumps: a vane pump supplied 90 gpm at 500 psi for traverse, and a piston pump supplied 9 gpm at 3000-psi for squeeze. We quickly learned that the small pump wore out in about eight hours and later found that the larger pump had to be replaced after about six months. Pump replacement was expensive (because of frequency) and difficult (because of location); and because the line operation was critical, management ordered us to drop everything and get on the problem.

We drained the reservoir, steam cleaned it, refilled it with fresh, clear fluid, left the covers off, and brought a couple of spotlights to the tank area so we could observe what happened when we next ran the system. We found that:

• a hairline crack on the inlet to the 90-gpm pump allowed air bleed into the system,

• the unload line from the 90-gpm pump discharged fluid directly at the inlet filter for the 9-gpm pump. We could actually see a stream of bubbles enter the filter to shot-peen the pump, and

• the rigid heavy outlet piping from the 9-gpm pump expanded at 2500-psi to distort and stress the pump housing, making it more susceptible to damage.

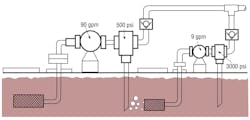

We replaced the cracked fitting, repiped both unload lines to point away from the inlet filters, and substituted a trombone expansion loop at the pump outlet to take the distortion before it stressed the pump housing.

As a result, the high-pressure pump now lasts a year or more and the low-pressure pump runs twice that before it needs to be replaced.

About the Author

Alan Hitchcox Blog

Editor in Chief

Alan joined Hydraulics & Pneumatics in 1987 with experience as a technical magazine editor and in industrial sales. He graduated with a BS in engineering technology from Franklin University and has also worked as a mechanic and service coordinator. He has taken technical courses in fluid power and electronic and digital control at the Milwaukee School of Engineering and the University of Wisconsin and has served on numerous industry committees.