Miniature Magnetic Pump 3D Printed as a Single Part

Content has been updated as of Oct. 13, 2021.

This article appeared in Machine Design and has been published here with permission.

To publicly demonstrate the powerful and as-yet-untapped capabilities of 3D printing, Luis Fernando Velásquez-García, a principal research scientist at MIT, had his team use it to make a miniature valveless pump.

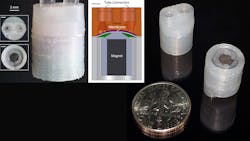

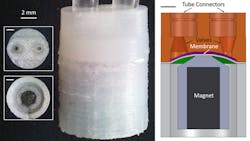

The hollow, cylindrical pumps, each about a cubic centimeter, have a membrane and fluid chamber closing off the top of the cylinder. Two ports on top of the chamber are attached to inlet and outlet tubes.

The team 3D printed the pump out of Nylon 12 in two different ways. In the first pump, it press-fitted a magnet into the cylinder. In the second monolithic pump, which was the first multi-material pump 3D printed monolithically—all in one piece, researchers embedded neodymium magnetic microparticles in the pump’s core. Nylon 12 was used because it is a good structural material that can absorb large amounts of magnetic particles.

It is also strong enough to hold the particles motionless while they are being magnetized, which lets the team create a strong permanent magnet. “In a softer material, the particles would wobble, resulting in no net magnetization of the magnetic composite,” explains Velásquez-García.

A magnet outside the pump rotates around it, causing the internal magnet to move the membrane, propelling the liquid or gas from one port to the other.

The pumps were tested for 14 million cycles; their leak-free performance surpassed that of the best 3D-printed miniature pumps and were as good as today’s commercial miniature vacuum pumps. The pumps can move liquids and gases using less power and with less clogging than conventional pumps of the same size. The pumps are also more portable than pneumatic and hydraulic pumps which must be tethered to an air supply or some source of pressurized fluid. Each pump was made in about 75 min. and used raw materials that cost less than $4.

The efficient pump could be used in applications from fuel cells to power generation to heat exchangers that cool computer chips, says Velásquez-García. He hopes that innovative pump will inspire others to explore computer-aided 3D printing and see the possibilities of moving to a new kind of manufacturing, one that fundamentally differs from the “cleanroom” mass-production style set by the semiconductor industry.

For example, the research team increases the pump’s stroke capacity beyond that of a conventionally made silicon pump by adjusting the printing process to make the membrane more flexible while keeping the body of the pump rigid, all using the same Nylon 12.

“The new magnetic pump is a clever implementation of the principle that ‘complexity is free’ in 3D printing,” says Albert Folch, a bioengineering professor at the University of Washington. “Because these pumps are made of several components of different materials and complex shapes, traditional manufacturing and assembly would be expensive.”

About the Author

Stephen Mraz

Steve serves as Senior Editor of Machine Design. He has 23 years of service and has a B.S. Biomedical Engineering from Steve was a Flight officer in the U.S. Navy. He is currently responsible for areas such as aerospace and medical.

Leaders relevant to this article: