Vegetable seed oils belong to a chemical family called “natural esters.” These are simply oils that are extracted from vegetable seeds. Nearly all types of seeds contain oil. However only some types are present in sufficient quantities or possess characteristics needed to be commercially viable lubricant oils.

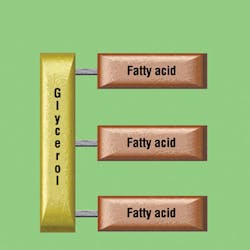

Chemically, natural esters are called triglycerides. These are made up of a glycerol molecule plus three molecules of fatty acids. Many different fatty acids occur naturally, which are simply chains of hydrogen and carbon atoms, attached by either single chemical bonds or double chemical bonds. Most naturally occurring fatty acids have chains with four to 28 carbon atoms. A simplified molecular structure of a triglyceride is shown in the illustration, on the next page.

The types of fatty acids in the natural ester molecule will determine the ester’s physical and chemical characteristics, such as viscosity, pour point, and especially, its resistance to oxidation. If the fatty acid portion of the molecule has many double bonds between the different carbon atoms, then the resulting natural ester will have poor oxidation stability because oxidation reaction occurs at the double bond.

Oleic acid is a fatty acid that is particularly stable with respect to oxidation. For this reason, natural esters with a high oleic acid concentration are generally more stable against oxidation or polymerization than natural esters containing less oleic acid. Oleic acid has only one double bond, which gives it higher resistance to oxidation, cross linking, or polymerization than other fatty acids.

But, again, only a few vegetable seed oils have the characteristics necessary to be commercially viable hydraulic fluids. Oils extracted from soy, sunflower, and rape (Canola) seeds have been the most widely used.

Applicable industry standards

The physical and performance characteristics of vegetable-based hydraulic oils vary with the type of base oil chosen and the additives that are used. Vegetable-based hydraulic oils from several different bases have been manufactured that meet key industry standardized tests, such as the Denison Vane Pump Test, the Eaton-Vickers 35VQ Vane Pump test, and the Sundstrand Piston Pump Test.

Vegetable oil advantages

Vegetable seed oils hold several advantages over standard mineral oil when used as a hydraulic fluid:

Higher flash and fire points — The ASTM D92 Open Cup Flash point of vegetable oils exceeds 320° C. This adds a significant margin of safety against fires in hydraulic systems, compared to an equivalent mineral oil based fluid, which typically has a flash point of about 130° C.

Biodegradable and non-toxic — Mineral-based hydraulic fluid is about 25 to 35% biodegradable in standard 28-day tests. Vegetable based fluids are 90 to 98% biodegradable in these same tests. Vegetable oils have also been determined to be non-toxic to fish. Depending on local environmental codes, this may allow hydraulic systems filled with vegetable-based fluids to be installed in environmentally sensitive areas where mineral oil would be perceived as a hazard. Also, spill cleanup regulations may give preference to natural ester fluids over petroleum-based fluids. (Again, local environmental codes should be consulted.)

Higher lubricity — Many natural ester base oils have very high natural lubricity, which protects hydraulic pumps from wear and premature failure. With proper additives, the lubricity of these fluids often surpasses that of mineral or even synthetic fluids.

Vegetable oil limitations

Of course, several disadvantages exist in using vegetable-based fluids instead of mineral oil in hydraulic systems. Most of these, fortunately, can be minimized through design changes.

Poorer oxidation resistance — Natural esters react with oxygen in a different way than mineral oils do. Instead of forming acids and then sludge, like mineral oils, natural esters will polymerize, or form a gel when they are at the end stage of their oxidation reaction. There is considerable debate in the industry regarding the suitability of applying standard mineral oil oxidation tests to natural esters, and there are task forces working in industry standards groups to answer this question and to find the most appropriate oxidation test standards for natural ester fluids.

Inferior low-temperature behavior — Vegetable oils have a pour point (the lowest temperature at which they will freely flow, under prescribed conditions) of about –21° C. For comparison, mineral hydraulic fluids have a pour point of –30 to 45° C., depending on the viscosity grade being tested. The higher pour point of natural esters will limit their application in hydraulic systems in low temperature environments.

Higher cost — Depending on the location and number of suppliers, natural esters cost 212 to 312 times the price of standard hydraulic oils.

Use and handling

In general, vegetable-based hydraulic fluids are used in the same way as standard mineral oil fluids.

Filling equipment — Vegetable-based hydraulic fluid is normally shipped from its manufacturer in 5-gal pails, 55-gal drums, or “tote” containers of 275 or 330 gal. Vegetable-based fluids should be segregated from other fluids and their identity clearly marked. Although natural ester fluids are miscible and physically compatible with some other fluids, it is not advisable to mix natural esters with mineral oil or synthetic fluids. Dedicated handling equipment should be used.

Most manufacturers of vegetable-based hydraulic fluids recommend minimizing contact between the fluid and air. This means keeping fluid containers sealed and maintaining a nitrogen atmosphere in previously opened containers (drums, totes, and bulk storage tanks) and in hydraulic systems filled with the fluids. Consult the fluid manufacturer for specific handling instructions.

Post-installation maintenance — Vegetable-based hydraulic fluids are maintained in much the same way as with mineral oils. The characteristics of used natural ester fluids are somewhat different than those of standard mineral oils because of the different oxidation reactions and aging processes that they undergo. For example, acceptable acid values and moisture content for used natural ester fluids will be much higher than those that are considered normal for mineral oils. Fluid manufacturers are the best source of information on characteristics of used oils that are considered acceptable for continued use.

What the future holds

Natural esters are expected to grow in popularity for several reasons:

• Lower fluid prices — As their use becomes more widespread, the price of natural esters will fall.

• Maturing Technology — Many hydraulic system owners or manufacturers have adopted a wait-and-see approach to natural ester fluids. As more guidance becomes available from industry standards groups, a greater user base will be developed, and natural esters will be seen as a more mainstream choice of hydraulic fluids.

• Greater environmental and fire safety awareness — In time, government regulating bodies will incorporate the fire and environmental safety advantages of vegetable seed fluids into fire and environmental codes. Industry experts predict that preference will be given in oil spill situations to fluids that are highly biodegradable, resulting in lower spill cleanup requirements and costs for users.

Although mineral oils will continue to be used in the majority of hydraulic systems for the foreseeable future, most experts believe that vegetable seed oil fluids will gain and hold an appreciable part of the market for themselves. The exact size of this share of the market is difficult to predict and will depend on such things as the number of manufacturers of these fluids, continued availability of inexpensive mineral oil and adoption of industry standard guidelines, and specifications. At this time, the future of natural ester hydraulic oils looks very good.

Conclusion

Vegetable-based, natural ester fluids offer several advantages in hydraulic system applications compared to other types of hydraulic fluids. Natural ester fluids have been successfully used in a wide variety of power transfer hardware, at both low and high pressures. Handling and maintenance procedures for natural esters are not significantly different from practices that are used for mineral hydraulic oils.

Natural esters are expected to grow in popularity and market share in coming years as environmental and fire safety regulations become stricter. Basic knowledge of the characteristics and application of natural esters will be a requirement of hydraulic power engineers and asset managers worldwide.

Dr. David Sundin is owner of SVB Environmental Lubricants, Sao Paulo, Brazil. Contact him at (903) 257-1036 or [email protected]. For more information, visit svbchemicals.com.

About the Author

David Sundin

Ph. D.

Leaders relevant to this article: