Can Zinc-Based Hydraulic Fluids Improve System Performance?

Engineers and designers often opt for zinc-based hydraulic oils based on their ability to resist wear and oxidation, along with their efficient performance. Still, some equipment manufacturers believe hydraulic oils with zinc increase sludge and varnish formation, which can raise maintenance costs due to plugged filters and a shorter oil life.

These manufacturers frequently rely on specific tests to identify oils that let sludge form. Some of the major tests used for this purpose include:

- The Bosch Rexroth A2F10 piston pump test (JCMAS P 045).

- The high-temperature Indiana stirring oxidation test (ISOT).

- The 1,000-hr turbine-oil oxidation stability test (TOST ASTM D4310).

- The dry-in-the-absence-of-added-water turbine-oil oxidation stability test (TOST ASTM D7873).

- The thermal stability test (ASTM D2070).

Until now, many zinc-based hydraulic oils have not performed well in these tests, especially the Bosch Rexroth A2F10 test. But engineers at Shell recently used this arsenal of tests to confirm that their new offering, a zinc-based hydraulic fluid, would reduce sludge formation and protect against wear and oxidation.

The new fluid is made using gas-to-liquids (GTL) technology. It converts natural gas, the cleanest-burning fossil fuel, into high-quality liquids that would otherwise be made from crude oil. GTL products are colorless and odorless, and have almost none of the impurities found in crude oil such as sulfur, aromatics and nitrogen.

GTL products include transport fuels, motor and hydraulic oils, and the ingredients for everyday necessities such as plastics, detergents, and cosmetics.

Here’s a look at the testing regime the new oil had to successfully pass to prove it can reduce sludge and varnish formation and have a longer operational life. The tests focused on the new synthetic oil’s performance in environments where zinc-based fluids have been traditionally expected to underperform their zinc-free counterparts.

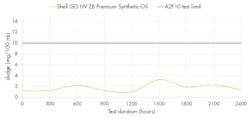

A2F10 Pump Test

This Bosch Rexroth piston pump test (JCMAS P 045) evaluates the oxidation stability of hydraulic fluids under operational conditions. The operational life for mobile equipment is based on this test and it is one of the few pump tests that calculates an oil’s ability to resist sludge formation. If the zinc-based fluid performed well in this test, it would mean the fuel’s overall formula affects sludge formation more than just the fact the formula includes zinc.

In the test, a Bosch Rexroth A2F10 pump sends a fluid pressurized at up to 350 bar (5000 psi) through a relief valve. A tank holds 13 liters of lubricating fluid at 80°C, and a copper specimen placed in the tank accelerates fluid oxidation. Air flowing at 1 L/hr sent into the inlet pipe also speeds oxidation.

Fluid samples taken at regular intervals are analyzed. Measured parameters including viscosity, viscosity change, increase in the acid number and foaming, and sludge levels. The total fluid volume decreases over time, thereby artificially increasing the oxidative stress on the fluid.

The oil-drain interval is then estimated as four times the number of successful hours in the test. (Actual oil-drain intervals can vary depending on the equipment used, operating temperature and maintenance practices.)

Shell’s new zinc-based fluid met and exceeded the A2F10 test limits even after 2,400 hr, which could indicate the oil’s operational life exceeds 9,600 hr.

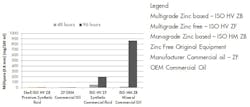

ASTM D4310

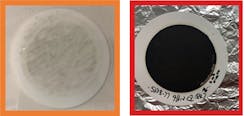

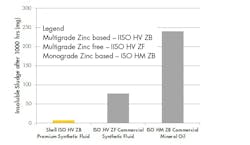

The ASTM D4310 TOST 1000-hr test determines a hydraulic fluid’s tendency to oxidize and its contribution to sludge formation and corrosion in the presence of heat, water and catalysts (copper and steel, materials commonly used in pumps). Sludge is filtered and reported at the end of test.

The reservoir holds the fluid at around 60 to 70°C, but it can get hotter when the pump operates, especially if the oil does not spend enough time (residence time) in the reservoir.

Typically, if a hydraulic fluid’s additives or base oil are thermally unstable, filter pads in the test would be significantly discolored and coated with sludge at the end of the 2,000-hr test.

Quantifying the sludge helps highlight the performance difference between the fluids.

The DIN sludge limit for this test is 200 mg at end of test. Pump OEMs requirements are even more stringent, requiring 100 mg or less at end of test.

The test found that then zinc-based fluid has significantly less sludge than the DIN standards, OEM limits, a commercial monograde (ISO HM) zinc-based mineral hydraulic oil and even a commercial multi-grade (ISO HV) zinc-free (ZF) synthetic hydraulic fluid.

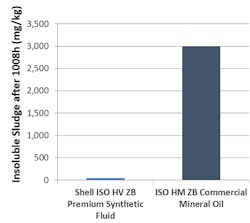

ASTM D7873

A third test for sludge, the ASTM D7873 Dry TOST test, is typically used for turbine oils rather than a hydraulic fluid. It indicates a lubricating fluids sludge and varnish forming tendencies by measuring its oxidative and thermal stability when heated to 120°C (about 250°C) with catalysts, but in the absence of water. 120°C might seem high, and typical hydraulic systems do not get this hot, but subjecting hydraulic lubricant to this test can help uncover any potential thermal stability issues. Technicians measured the sludge level according to ASTM D7873 after 1,008 hr into the test.

Quantifying the results, the sludge measured for the new synthetic zinc-based lubricant was statistically less than that formed by the commercial mineral oil. This data underscores the fact that if formulated carefully, zinc containing fluids can reduce or prevent sludge formation properties.

High-Temperature Test

The high-temperature Indiana stirring oxidation test, done according to JIS K2514, also checks the oil’s oxidation and sludge formation characteristics and it does so under conditions that promotes oxidation: blowing dry, hot (165°C) air and including oxidation catalysts. Fluid samples are forced through paper filters to calculate sludge build-up.

Fluids that do well in this test likely have excellent thermal stability.

This test is typically used to test compressor lubricants. Lubricants formulated with zinc-free chemistries have less sludge formation in this test. Thus, this test is considered “favorable” to zinc-free lubricants.

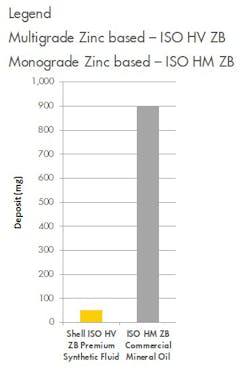

ASTM D2070 Test

This thermal stability test evaluates a lubricant’s ability to resist breakdown under high temperatures. In the test, a fluid sample with catalysts added is heated to 135oC for 168 hr. No air or oxygen is added to promote oxidation—just heat—and the sample is not agitated. After the test, sludge deposits are weighed. as are the weight losses of the catalysts.

This test simulates environments in which wear and corrosion might arise from copper surfaces rubbing against steel surfaces. This test is considered particularly important in assessing a lubricant’s ability to resist sludge formation on phosphor, which is used in the bronze slipper pads commonly found in axial piston pumps.

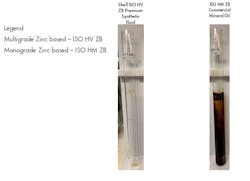

The Varnish Test

This test, a proprietary Shell in-house test, accelerates varnish formation on aluminum rods using temperature cycling. The company developed what it considered a much-needed test for varnish formation. The aluminum rods are weighed before and after being put in different fluids, and then the mass of varnish on each rod is measured.

Varnish is a tough, adherent oxide or carbonaceous material that coats the internal surfaces of machines such as pumps. Hot surfaces, as well as long-term operations, turn varnish into a hard, shiny, brittle coating. In contrast, sludge, which is sometimes a precursor to varnish, is soft and sticky and can move through the system until it finally comes to rest—usually at sump bottoms, troughs, strainers, filters, and narrow fluid passages. Varnish can prematurely wear important hydraulic components and cause pump failures. It can also make the system overheat, plug filters, and make valves stick, leading to costly unplanned maintenance.

Key characteristics for a good hydraulic fluid are that it protects against wear and minimize sludge and varnish formation. Zinc-based fluids do all of this, but not all zinc-based fluids are the same. After undergoing all these tests, however, researchers concluded that Shell’s gas-to-liquid technology can be used to make effective zinc-based fluids.

Sravani Gullapalli is an associate technology manager and Sameer Sathaye is a project leader for industrial lubricants at Shell Global Solutions (U.S.) Inc.