The Right Seal Reduces Contamination in Hydraulic Systems

Contamination is estimated by hydraulic experts to cause 65% to 90% of all hydraulic system failures, making it a major cause for concern for fluid power engineers. And although filters have improved, oil can still become contaminated and cut short the life of hydraulic equipment.

Causes of Contamination

There are four main causes of contamination in hydraulic systems: particles left in the system during manufacturing; oil that is not properly filtered before it enters the system; particles and condensing water that get into the hydraulics through an opening or by bypassing the seals; and particles created by wear on one or more components.

Component wear, in turn, is caused by:

- Abrasion when lubricated surfaces contact one another, or clearance-sized particles damage a lubricated surface.

- Adhesive wear (or friction welding) that removes material from one surface through erosion.

- Fatigue, or point loading, that elastically deforms a component’s surface.

- Erosion caused when silt-sized particles in a fluid form an abrasive slurry that erodes surfaces.

- Cavitation caused by vapor or air bubbles collapsing under pressure, which erodes metal parts.

- Corrosion caused by chemical byproducts, such as acids, that attack some metals when hydraulic oil is degraded by water or heat.

Regardless of how wear occurs, contamination by particles inside the system (internal) or that mange to get inside (ingress) can be mitigated or prevented with the appropriate seals.

Seals to the Rescue

Seals can be separated into four categories: hydraulic, wiper and static seals, along with wear rings.

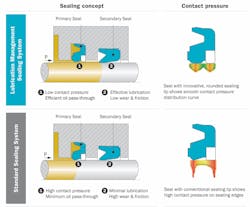

Hydraulic seals primarily prevent leaks. They can also help limit internal contamination through Lubrication Management, an approach that uses specially engineered seals to regulate lubrication between primary and secondary seals. This reduces heat generation and minimizes wear, increasing the components’ service lives. Less heat also lets hydraulic fluid last longer and not degrade, while reduced wear lowers the amount of particulates generated from the seals and their counter surfaces.

Wiper seals feature an outer scraping lip designed to prevent ingress of contamination. They are placed facing the external environment on dynamic surfaces where they are exposed to a variety of debris—such as water, dust and mud—common in hydraulic applications.

Wipers must exert the right amount of scraping force to ensure contaminants stuck to external portions of a rod are dislodged on each stroke. In many cases, a bi-directional wiper is used for additional oil film control.

Poorly regulated oil films can appear to be leaks and may let debris stick to the rod. Ensuring the wiper is correctly specified avoids this and lowers the likelihood of contamination.

Wear rings are parts of most hydraulic sealing configurations. They absorb transverse forces and prevent metal-to-metal contact, a common source of internal contamination.

Misaligned parts rubbing together can create and release metal particles into a hydraulic system. These particles become caught in the hydraulic fluid and carried throughout the system, causing wear on components and clogging fluid passages. Proper wear ring arrangements based on expected loads can prevent this.

Static seals are used throughout hydraulic systems and are often the last line of defense against internal leaks and outside debris getting into the hydraulics. They are typically located near threaded components. Therefore, it’s critical to avoid damaging them during installation. In higher pressure applications, hardware can sometimes balloon, increasing the space between metal components. In these situations, it’s important to specify the proper squeeze to ensure the seal retains enough sealing force to function.

Considering Materials

Selecting materials for the seal components is important and often complex. The first and most obvious consideration is chemical compatibility with the hydraulic fluid and other media. For example, components made of ethylene propylene (EPM) and ethylene propylene diene monomer (EPDM)-based materials resist acids, ketones and alcohols, but are not recommended for petroleum oils or mineral oils. Similarly, nitrile rubber (NBR) is recommended for hydraulic fluids, but not for systems containing chlorinated hydrocarbons or ketones.

Temperature is also a factor. To get the longest optimized seal life, sealing materials must be matched to the hydraulics’ maximum and minimum operating temperatures. For dynamic seals, frictional heat must also be considered because it can cause the temperature at the seal interface to be higher than the bulk fluid temperature.

System pressure is also important as high pressures can lead to the seal’s material flowing into gaps in the hardware and potentially breaking off. This can be prevented if the hardware is designed with tighter gaps.

If heavy internal contamination or ingress is a risk, a durable, abrasion-resistant seal material can limit damage and extend system life. Working with a knowledgeable seal supplier at the beginning of a project can help ensure all elements within the seal are properly selected based on specific working conditions.

Storing Seals

Some seals stored for extended periods or that are improperly stored can harden, soften or crack. Sealing suppliers can provide recommendations for storing elastomers and the shelf-life limits for specific materials so they can be used before they degrade. Seals should not be used after they pass their shelf-life date.

In general, elastomer seals should be stored in individual sealed envelopes or corrugated boxes at temperatures below 77°F with relative humidity less than 70%. The sealed envelope helps protect them from light and ozone-generating equipment, both of which can breakdown seal materials. The envelope also keeps seals away from contact with liquids, metals and dusting powders that can weaken them.

Installation

Seal suppliers typically provide instructions for installing standard seals. For custom seals, they prescribe application-specific installation methods. At the same time seals are designed, engineers should consider the installation process that will prevent damage to the seals. For instance, sharp edges should be avoided.

Generally, to prevent seal damage during installation, technicians should:

- Maintain a clean, tidy and well-lit assembly area.

- Make sure all necessary installation tools, fixtures and materials are readily available.

- Remove machining residues, such as chips, dirt and other foreign particles.

- Deburr and chamfer sharp edges.

- Cover the tips of screw threads.

- Ensure installation tools do not have sharp edges.

- Make sure cylinder bores and rods have correct lead-in chamfers or use a calibration sleeve.

Because hydraulic systems rely on fluids to transfer and amplify power, as well as lubricate vital components, it’s best to understand and counteract potential contamination and wear issues during the design of seals for hydraulics systems.

Understanding the four causes of contamination in hydraulic systems—as well as chemical compatibility, temperature, system pressure, and proper storage and installation—can help engineers choose the right seal, prevent contamination, avoid costly hydraulic failures and extend system life.

Beth Figliulo is a manager in the fluid power segment manager and Michael Cook, is a fluid power technical specialist at Trelleborg Sealing Solutions.

About the Author

Beth Figliulo

Fluid Power Segment Manager

Michael Cook

Fluid Power Technical Specialist, Trelleborg Sealing Solutions

Leaders relevant to this article: