Download this article as a .PDF

Equipment designers and users love what the power and control of hydraulics can do for productivity. Yet, when a machine requires a human operator to achieve that, productivity and safety must go hand in hand. Whether dealing with the uneven terrain of construction sites and agricultural fields, or keeping a forklift and its load upright on a relatively level warehouse floor, the safety of workers depends on loaded forklifts staying stable and upright in all types of environments. Toyota’s System of Active Stability (SAS) was designed to directly improve vehicle stability by automatically stabilizing loads during high lifting and reducing the possibility of the forklift and its load tipping over as it turns.

How It Works: A Triangle Becomes a Rectangle

Four-wheeled forklifts are generally designed with a three-point load distribution: the two front wheels and a rear pivot point at the center of the truck’s rear axle. The stability of the forklift depends on where their center of gravity is, so they are designed to pivot at this central point. However, an uneven load or radial force from turning can cause the vehicle to tilt to one side. As long as the center of gravity stays within the triangle formed by the three distribution points, the vehicle remains stable. However, if the vehicle’s center of gravity falls out of this triangle, the wheels could leave the ground, and the vehicle may tip over.

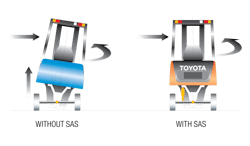

To prevent this, an SAS-equipped forklift contains a lateral acceleration/yaw sensor that detects radial forces while turning. A signal is routed to the vehicle’s electronic control unit (ECU), and if the signal approaches a value of potential instability, the ECU activates the SAS system. The SAS system uses a single-rod hydraulic cylinder with self-contained fluid mounted on one side of the forklift between the axle and forklift body. Fluid can flow freely between two chambers on each end of the cylinder through a normally open solenoid valve. However, if the radial force exceeds the threshold value, the acceleration/yaw sensor signals the vehicle’s ECU to energize the solenoid valve, thereby closing the passage of fluid between the chambers. This locks the cylinder’s piston rod in place.

This locking and unlocking happens so rapidly that most of the time the operator is not aware of it. The resulting increase in stability reduces the likelihood of a lateral overturn. The rear axle now has two load distribution points instead of one. Consequently, the travel area of the center of gravity within these four points is larger than that in a triangle, thus contributing to lateral stability.

High Expectations for Safety

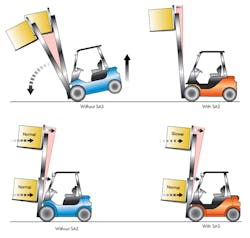

It’s not unusual for today’s warehouses to require placing and retrieving loads to heights of 20 ft. or more. An improper move by an operator could cause a load to fall off the forks. The challenge is allowing the forklift to operate quickly for high productivity, yet remain safe when working at high elevations. Toyota’s SAS feature achieves both by limiting mast tilt and tilt speed once the forks are higher than a pre-determined height established by placement of a limit switch and a load sensor.

When the operator raises the mast higher than the limit switch, it signals the ECU and the ECU looks at the load sensor. The ECU determines the weight, and then energizes a flow-control system that limits tilt speed to a preset value based upon those values. The ECU also limits stroke of the tilt cylinders to keep the operator from tilting the mast too far forward, thus preventing load spills or tipping the forklift forward.

The tilt can be limited up to one degree of forward tilt depending on the weight of the load and the height. For applications that might require the mast to have a different tilt starting point other than vertical, the setup of the forklift can be changed to allow for this. This allows attachments like paper roll clamps to work with the system effectively.

Operator Must Stay Mentally Active

All that said, Toyota advises customers that systems like SAS are no substitute for proper operator training on any riding equipment. In fact, training must be partnered with advancements of this type. Training can prevent those situations where no amount of hydraulic or electronic assistance could prevent an incident. Systems like SAS are there to help guide operators or provide confidence to help increase productivity, not to replace operator smarts.

Looking toward the future, the use of advanced electronics in the automotive world is enabling improvements in industrial forklifts as well. Automotive features such as lane departure control, brake assist, and the development of self-driving vehicles are being looked at to see how they can be adapted to the unique environment of the forklift.

ECU improvements being driven by these technologies will make it easier to adopt items like wireless self-guidance and auto braking systems using radar or laser sensors, and productivity enhancements like auto shelf-level fork location based on the pick location. These items will continue to need a blend of hydraulic and electrical components to meet the performance required.

As long as end users continue demanding more productive and efficient industrial vehicles, technological advancements in all forms of power transmission will continue.

Mark Faiman is product manager for engine powered forklift and aerial work platforms at Toyota Material Handling USA.