Bobcat Triples Productivity with New Bore-Finishing System

Tightening the Process

Previously, Bobcat finished the control valves on its skid-steer hydraulic pump bodies by using a multipass honing system that required operator manipulation with each part. The honing machine would make a pass to finish three 15.877‑mm (0.6251-in.) diameter bores on the G2 steel casting. Then, an operator would move the part 180° on the die so the machine could make a second pass through the valves on an off-set bore.

“We had to take extra measures to make sure the valves wouldn’t leak,” said Dean Cota, Bobcat Sr. Manufacturing Engineer. “We had to run the honing system through multiple times because each spindle had only one stone on it. Each head would go through the bore three times to perform the roughing, semifinish, and finish steps. Then we would manually reposition the part and run it through again.”

The finishing process was slow and required extra operator care to guarantee tight bore tolerances. While researching other honing options that would improve productivity, Cota discovered Engis’ single-pass bore finishing, which provides a multispindle head that hones with three/four tools in close proximity to each other. This unique arrangement allows the roughing, semifinish, and finishing operations to be performed simultaneously on all of the valve bores in a part.

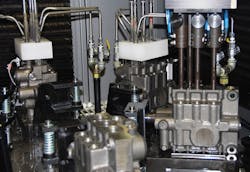

Engis custom designed the single-pass bore finishing system to Bobcat’s specifications. The machine has six stations for which the part is transferred through by a rotary index table.

- Station #1 is the load/unload position.

- In station #2, a vision system is used to verify that the part is loaded correctly and that the proper part is present for the current program being run.

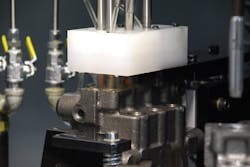

- Stations #3, #4, and #5, each have independent servo controlled columns, with four spindle multiheads for holding the diamond honing tools.

- Station #6 utilizes an independent servo controlled column with a head holding four multijet gage probes. This gauge unit allows every land of every bore to be inspected in the X and Y planes for size. The gauge also has advanced features which allow it to measure the bore sizes of the rough and semifinish operations on command.

The Engis system achieves tolerances to 0.5 μm (0.000020 in.) ensuring bores are consistently straight and cylindrical, which are critical for the spool and valve bore to fit properly in the hydraulic system. When hydraulic valves perform optimally, they can withstand a higher pressure, which improves overall performance of the skid-steer loaders.

The single-pass boring process is achieved through a series of progressively finer, high-precision electroplated diamond tools. The diamond size grit on the tools are to 100/120, 200/230, and 325/400. The free-floating nature of the tooling results in superior bore consistency and a faster cycle time.

The old multipass honing system took 253 sec/part, which included two boring passes, resetup of the machine and flipping parts. The new single-pass boring system takes 89 sec, improving throughput by nearly 300%.

Reducing Errors

By automating the bore finishing system and reducing operator contact with the parts, Bobcat has reduced the chance for mistakes.

Operator transition to the new single-pass bore finishing system was simple due to built-in CNC programming. The machine’s vision system identifies that the right parts are loaded before the program runs, which further prevents errors.

The advanced gauging system 100% inspects and measures the bores for geometric precision so that every part coming off the line is exactly to spec.

Because the single-pass process spreads the workload over a series of high-precision electroplated diamond tools, Bobcat requires very few tooling changes, which saves on consumable costs.

“We ran the machine for six months, six days a week for 20 hr a day before we had to change the tooling. At an average run of 165 parts/day, we produced nearly 24,000 parts before we needed to change out the tooling,” noted Cota.

The new Engis bore finishing system has decreased cycle times to the point that the plant can take on additional honing production without requiring any additional capital investments.

____________________

JOHN SMALLSHAW, vice president of sales and marketing, Engis Corp., Wheeling, Ill. For more information, visit www.engis.com or visit them at IMTS Booth N-6751.