EXAIR 1/2 NPT HollowStream Spray Nozzle Creates Cone Spray Pattern for Pressurized Liquids

EXAIR developed the 1/2 NPT HollowStream liquid atomizing spray nozzle to provide users with a device capable of creating a hollow cone spray pattern suited for use with pressurized liquids. The nozzle can be used for cooling, cleaning, rinsing and dust suppression in industrial applications.

Features of the 1/2 NPT HollowStream nozzle include:

- right angle design fits small spaces

- liquid operating pressure up to 250 psi

- uniform liquid distribution

- available in various flow rates.

Designed for Uniform Liquid Distribution

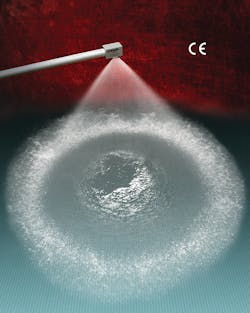

The EXAIR 1/2 NPT HollowStream liquid atomizing spray nozzle is able to produce a hollow cone spray pattern due to the inclusion of a vortex chamber in the nozzle. A swirling action is created when liquid enters the body of the nozzle. As it exists the nozzle's orifice and liquid surface tension is broken, the spray pattern is created in a controlled manner.

Liquid emitted from the nozzle is distributed in a uniform manner, in a ring pattern with medium to large droplets explains EXAIR in its press release announcing the launch of the spray nozzle.

READ MORE: Clearing (and quieting) the air

The nozzle is capable of working with liquid pressures up to 250 psi and features an adjustable flow rate which the company says benefits use for dust mitigation, pollution scrubbers, foam breaking and other similar applications.

A vaneless, tangential flow design combined with wide open internal features help to prevent the nozzle from clogging. This enables the nozzle to still emit liquid even if it contains particulate.

The liquid atomizing nozzle is made of type 303 stainless-steel, ensuring durability and corrosion resistance. It is CE compliant as well, assuring performance and safety in various use cases.

About the Author

Sara Jensen

Executive Editor, Power & Motion

Sara Jensen is executive editor of Power & Motion, directing expanded coverage into the modern fluid power space, as well as mechatronic and smart technologies. She has over 15 years of publishing experience. Prior to Power & Motion she spent 11 years with a trade publication for engineers of heavy-duty equipment, the last 3 of which were as the editor and brand lead. Over the course of her time in the B2B industry, Sara has gained an extensive knowledge of various heavy-duty equipment industries — including construction, agriculture, mining and on-road trucks —along with the systems and market trends which impact them such as fluid power and electronic motion control technologies.

You can follow Sara and Power & Motion via the following social media handles:

X (formerly Twitter): @TechnlgyEditor and @PowerMotionTech

LinkedIn: @SaraJensen and @Power&Motion

Facebook: @PowerMotionTech

Leaders relevant to this article: