Air Motor Selection and Sizing

Air motors are used to produce continuous rotary power from a compressed air system. They boast a number of advantages over electric motors:

- Because they do not require electrical power, air motors can be used in volatile atmospheres.

- They generally have a higher power density, so a smaller air motor can deliver the same power as its electric counterpart.

- Unlike electric motors, many air motors can operate without the need for auxiliary speed reducers.

- Overloads that exceed stall torque generally cause no harm to air motors. With electric motors, overloads can trip circuit breakers, so an operator must reset them before restarting equipment.

- Air motor speed can be regulated through simple flow-control valves instead of expensive and complicated electronic speed controls.

- Air motor torque can be varied simply by regulating pressure.

- Air motors do not need magnetic starters, overload protection, or the host of other support components required by electric motors.

- Air motors generate much less heat than electric motors.

As one would expect, electric motors do possess some advantages over air motors:

- If no convenient source of compressed air exists for an application, the cost of an air motor and its associated support equipment (motor-driven compressor, controls, filters, valves, etc.) will exceed that of an electric motor and its support equipment.

- Air motors consume relatively expensive compressed air, so the cost of operating them will probably be greater than that of operating electric motors.

- Even though electronic speed controls escalate the cost of electric motor drives, they control speed more accurately (within ±1% of desired speed) than air motor controls do.

- Air motors operated directly from a plant air system are susceptible to speed and torque variations if system flow and pressure fluctuate.

Common designs of air motors include rotary vane, axial piston, radial piston, gerotor, turbine, V-type, and diaphragm. Rotary vane, axial- and radial-piston, and gerotor air motors are most commonly used for industrial applications. These designs operate with highest efficiency and longevity from lubricated air. Of course, specific designs are available for applications where lubricated air proves undesirable. Turbine motors are used where very high speed but low starting torque are required. V-type and diaphragm air motors are used primarily for special applications and will not be covered here.

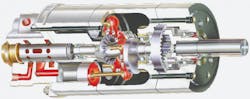

Piston motors

Piston air motors are used in applications requiring high power, high starting torque, and accurate speed control at low speeds. They have either two, three, four, five, or six cylinders arranged either axially or radially within a housing. Output torque is developed by pressure acting on pistons that reciprocate within the cylinders.

Motors with four or more cylinders provide relatively smooth torque at a given operating speed because power pulses overlap: two or more pistons undergo a power stroke at any time within a revolution. Motors designed with overlapping power strokes and accurate balancing are vibration-free at all speeds.

Power developed by a piston motor depends on the inlet pressure, the number of pistons, and piston area, stroke, and speed. At any given inlet pressure, more power can be obtained from a motor that runs at a higher speed, has a larger piston diameter, more pistons, or longer stroke. Speed-limiting factors are the inertia of the moving parts (which has a greater effect in radial- than in axial-piston motors) and the design of the valve that controls inlet and exhaust to the pistons.

Radial- and axial-piston motors have one significant limitation: they are internally lubricated, so oil and grease supplies must be checked periodically and replenished. They must be mounted in a horizontal position to provide proper lubrication to bearing areas. However, at least one manufacturer offers a radial-piston motor with the shaft vertically-down as a standard configuration. Other mounting positions from any manufacturer require special lubrication configurations.

Radial-piston motors feature robust, oil-lubricated construction and are well-suited to continuous operation. They have the highest starting torque of any air motor and are particularly beneficial for applications involving high starting loads. Overlapping power impulses provide smooth torque in both forward and reverse directions. Sizes range to about 35 hp for speeds to 4,500 rpm.

Rotary vane motors normally are used in applications requiring low- to medium-power outputs. Simple and compact vane motors most often drive portable power tools, but certainly are used in a host of mixing, driving, turning, and pulling applications as well.

Vane motors have axial vanes fitted into radial slots running the length of a rotor, which is mounted eccentric with the bore of the motor's body housing, Figure 2. The vanes are biased to seal against the housing interior wall by springs, cam action, or air pressure, depending on design. The centrifugal force that develops when the rotor turns aids this sealing action. Torque develops from pressure acting on one side of the vanes. Torque at the output shaft is proportional to the exposed vane area, the pressure, and the moment arm (radius from the rotor centerline to the center of the exposed vane) through which the pressure acts.

In a multi-vane motor, torque can be increased at a given speed by increasing the air pressure at the motor inlet to increase the pressure imbalance across the motor vanes. However, there are tradeoffs: increasing inlet air pressure increases air supply costs and generally leads to faster wear and shorter vane life.

Output power at a given speed determines air consumption. A small motor producing 1 hp and operating at 2,000 rpm using 80-psi air consumes the same volume of compressed air as a larger air motor producing 1 hp at 2,000 rpm using air at a lower, more economical pressure.

Rotary vane air motors are available with three to ten vanes. Increasing the number of vanes reduces internal leakage or blow-by and makes torque output more uniform and reliable at lower speeds. However, more vanes increase friction, cost of the motor, and decrease efficiency.

If, in a 3-vane design, one vane sticks in a retracted position, it can prevent the air motor from starting under load. Spring-biasing the vanes against the housing wall, porting pressure air to the base of the vanes, or camming the base of the vane prevents this problem, as does using a motor with four or more vanes.

Vane motors operate at speeds from 100 to 25,000 rpm at the rotor - depending on housing diameter - and deliver more power per pound than piston air motors. Because the vanes slide against the housing wall, many vane motors require lubricated air, particularly if short duty cycles are followed by long inactive periods. However, more and more motors continue to be designed to operate on non-lubricated air to serve critical applications and environmental concerns.

Operation of ungoverned vane air motors with no load at high speed should be avoided. When a multi-vane motor operates ungoverned under no load, its high speed can heat and char the vane tips as they rub against the cylinder wall. Abnormal wear and damage to other motor parts should also be expected.

Vane-type air motors are available in four basic mounting configurations: base, face, hub, and NEMA-flange. Base-mount models simply bolt onto a sub-base, and the load is belt-driven or directly coupled. Face and hub mounts are used when the motor must be mounted through a bulkhead or as an integral part of a driven device. NEMA-flange mounts enable air motors to directly replace NEMA-frame electric motors.

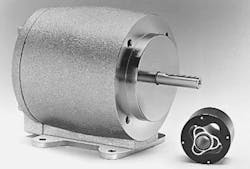

Gerotor air motors

Gerotor air motors, Figure 3, deliver high torque at low speed without additional gearing. When coupled with a 2-stage orbital planetary gear train, gerotor power elements provide torque at speeds down to 20 rpm. These motors are well suited to hazardous-environment applications where relatively high torque is needed in limited space.

Low-speed/high-torque gerotor air motors can deliver torque exceeding 250 lb-in. within a speed range of 20 to nearly 100 rpm from a 90-psi supply of compressed air. They are rated for continuous operation at supply pressures to 150 psi. Low rotating inertia of the gerotor design produces instant starting, stopping, or change in direction when the valve supplying the motor is shifted. Furthermore, the design prevents the motor from coasting or being backdriven, which can eliminate the need for external brakes. Like vane motors, they are much less sensitive to mounting orientation than piston motors are.

Turbine motors

Efficiency of an air motor is defined as the ratio of the actual power output to the theoretical power available from the compressed air for the expansion ratio at which the machine is operating. Turbines convert pneumatic power to mechanical power at about 65% to 75% efficiency. Turbine efficiency is higher than other air motors because sliding contact of parts does not occur to cause internal friction. As a result, there is no need for extensive lubrication. The absence of lubricating oil dramatically improves cold-weather performance.

Until recently, turbine air motors typically were used for applications requiring very high speed and very low starting torque - dental drills and jet aircraft engine starters being most typical. Now, however, turbine technology is being applied to starting small, medium, and large reciprocating engines. Turbine technology offers simple, highly efficient pneumatic starters that require no lubrication of their supply air, tolerate contaminants in the supply air, and need little maintenance. Turbine starters include a planetary gear reduction to bring the turbine's high rotor speed down to normal engine cranking speeds.

Turbine motors are relatively compact and light for their power-delivery capability. Higher gear ratios - from 9:1 through 20:1 - provide high stall torque and versatility for a variety of engines. Turbine horsepower is easily changed by limiting air flow through the motor.

Operation of a turbine air motor involves a nozzle that directs and meters air to a turbine wheel or rotor. It changes high-pressure, low-velocity air flow to low-pressure, high-velocity. The mass-flow rate of air passing through a turbine determines its horsepower. Changing the number of nozzles or nozzle passages changes power output proportionally. If a 16-nozzle starter is reduced to 8 nozzles, the altered starter will produce half the power of the original. Therefore, within the same basic starter configuration, many models can be designed that have a wide range of inlet pressures, cranking speeds, and cranking or stall torques. This capability, combined with various gearboxes, allows production of low-cost starters for a wide variety of applications. For example: turbine starters are available to crank engines with displacements from 305 to 23,800 in.3 at pressures from 40 through 435 psig.

Performance characteristics

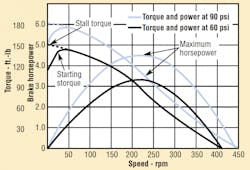

Power characteristics of air motors are similar to those of series-wound DC motors. With a constant inlet pressure, the brake horsepower of an air motor is zero at zero speed. Power increases with increasing speed until it peaks at around 50% of free speed (maximum speed under no-load conditions), Figure 4.

At the peak point, torque decrease balances speed increase. Power decreases to zero when torque is zero, because all the inlet air power is used to force the volume of air required to maintain this speed through the motor.

Torque output for an air motor of given displacement theoretically is a function of the differential pressure and a constant that depends on the physical parameters of the motor. Therefore, regardless of speed, torque should be constant for a given operating pressure. Actually, this is not the case, because as air flow increases through the motor, pressure losses in the inlet and outlet lines consume a greater portion of the supply. In practice, torque reaches its greatest value shortly beyond zero speed, Figure 4, and falls off rapidly until it reaches zero at free speed.

Starting torque is the maximum torque the motor can produce under load. It is about 75% of stall torque. It takes more torque to start an air motor than to keep it running. Do not confuse stall and starting torques. If the air motor load exceeds its starting torque, the motor will not start.

Stall torque, the maximum torque of an air motor, is about twice the torque at rated horsepower, and can be determined from information on power and speed given in manufacturers' literature. The relationship between torque and rated power is:

T = 5250 P / n

T is torque in lb-ft

P is power in hp, and

n is speed in rpm.

Because stall torque is about twice torque at rated power, if n is 525 rpm, and P is 0.03 hp, then T is 3 ft-lb, and starting torque is 2.25 ft-lb.

Rated power generally refers to maximum horsepower at 90 psi. Although air motors typically can operate at pressures from 20 to 150 psi at the intake, usual practice limits operating pressure to between 30 and 100 psi.

To compare motors rated at different inlet pressures, use this rule of thumb: reduce horsepower 14% for each 10-psi reduction in air pressure. Conversely, a 10-psi reduction in air pressure will cut motor efficiency by 14%. Obviously, this relationship directly affects productivity. Again, this is only a rule of thumb and does not apply exactly to any particular motor model.

Be sure to measure supply pressure at the motor inlet. It is not enough to determine that there is 90-psi supply pressure at the compressor - line losses usually reduce that pressure before it reaches the air motor. There must be 90 psi at the motor inlet for the motor to perform at rated torque and horsepower.

Controlling air pressure supplied to the motor is the simplest and most efficient method of changing the motor's operating characteristics. Conversely, not maintaining the required supply pressure at the motor inlet certainly degrades operating characteristics.

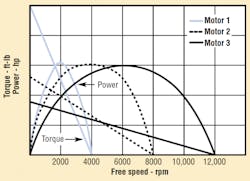

There is no direct relationship between power and speed; that is, the lowest horsepower does not indicate the highest speed or vice versa, Figure 4.

Free speed is the maximum speed of the motor under no-load conditions. For a governed motor, the term free speed actually means free governed speed, or the maximum speed at which the motor will run while the governor is operating.

Design speed is that speed at which rated horsepower is reached. It is about half the free speed of a non-governed motor, and 80% of free governed speed of a governed motor. An air motor operates most efficiently at design speed.

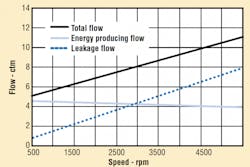

Because air motors are constant-displacement devices, their speed, theoretically, is directly proportional to air flow rate. This is true if there is no leakage, but leakage certainly affects motor speed. Leakage increases with pressure, and is nearly constant at any given pressure. Thus, at fixed speed, air consumption increases as supply pressure increases; at low speeds, a much higher proportion of total flow is lost through leakage.

A typical air motor performance curve, Figure 5, shows that the additional increment of flow per rpm is nearly constant. Notice, though, that total flow per revolution decreases as speed increases. Leakage also decreases slightly as speed increases, because less time is available for leakage.

When the load on an air motor increases, speed decreases until motor torque meets that load requirement. Opening the throttle to the motor to increase inlet air pressure may bring the motor up to rated speed.

For applications involving varying loads, the major consideration is whether the motor can provide enough power for all operating conditions. Motors producing the same maximum horsepower but with different torque characteristics can exhibit substantial differences in speed, depending on load, Figure 6. On the other hand, if you wish to reduce change in speed with varying load, select a motor with a steep torque curve, Figure 7. This is because the steeper the torque curve, the less speed changes with load.

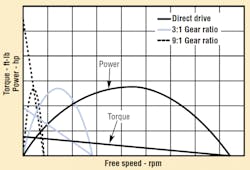

The influence of the load can be reduced by installing speed-reduction gearing between the motor and the load. This decreases output speed while retaining the same power to increase the slope of the torque curve. Remember, maximum power usually occurs at 50% of free speed, so reducing free speed also reduces design speed, Figure 6. Gearing also reduces efficiency.

Another good rule of thumb is to choose an air motor that provides the required horsepower and torque at about 2/3 of available air supply pressure. Full line pressure then can be used for starting and overloads.