Unlocking the Canal's potential

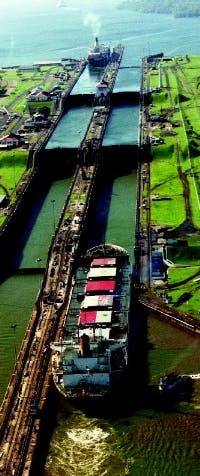

Ships from all over the world travel through the Panama Canal every day. In an average year, more than 14,000 vessels on international voyages (representing approximately 4% of world trade) pass through this famous waterway. In 1998, the Panama Canal Authority decided to accelerate its mission to upgrade the Canal to meet projected demand increases. The goal was to modernize cumbersome mechanical systems and streamline operation and maintenance.

One key area identified for upgrade in the $700 million project was the waterway's trademark lock operating system. The system's antiquated mechanical design was in need of a complete overhaul. As part of the modernization effort, Bosch Rexroth Corp.'s Industrial Hydraulics technology group was awarded a multi-year contract to manufacture new hydraulic systems for the Panama Canal locks' miter gates.Hydraulic drives for lock operation

The Panama Canal is 50 miles long, connecting the Atlantic and Pacific Oceans. Winding through one of the narrowest and lowest areas of the isthmus' long mountainous terrain, the canal crosses the Continental Divide at an elevation of 85 ft above sea level. Travel through the canal by an average ship requires about ten hours.

As each ship is raised or lowered in the 110 1000 ft lock chambers, they are sealed in the lock on either end by miter gates. Rising stem valves and cylindrical valves allow water to be transferred from chambers with higher elevations to chambers with lower elevations. Each has mechanical linkages that connect to small gate-like structures that can block the passage of water through culverts at the bottom of the chambers.

Previously, all of the miter gates, rising stem valves, and cylindrical valves had been driven mechanically. However, over the last six years, Bosch Rexroth has systematically replaced the antiquated mechanical drives of all 80 miter gates with hydraulic drive systems — improving lock efficiency, functionality, and streamlining daily operations and maintenance.

A custom system

Each new system includes custom hydraulic power units using variable-displacement, axial-piston pumps, custom manifolds, stainless steel reservoirs, hydraulic cylinders with customized base mounting attachments, piping, plus safety and instrumentation systems.

A component of the hydraulic solution, an AA4VSO axial-piston pump with 125 cc/sec maximum flow capability, supplies stepless motion control via a proportional valve with electrical feedback. The pump is a swashplate design for open circuit operation. The pump's output is infinitely variable, via adjustment of its swashplate angle. Although the pump is rated to 5100 psi, the actual system operates at less than 3000 psi.

The pump control also includes a pressure compensator. As long as the system pressure is below the pressure compensator setting, the pump output flow is governed by the proportional valve. If the system pressure goes above the compensator setting, then the output flow is minimized. The speed of the miter gate is determined by the output flow of the pump. The output flow is set by means of an electronically operated proportional directional valve. This valve is integral to the pump control. The pump's swashplate angle is fed back via an inductive position transducer.

Smart cylinders

Cylinders are directly attached to the miter gates. As a cylinder extends, water level is adjusted when the miter gates close. This seals the lock chamber from the adjacent one. Once the water levels are equal, the cylinders retract to open the miter gates so ships can pass.

Each cylinder has a bore of 15.7 in., rod diameter of 9.5 in., and stroke of approximately 18 ft. The system is such that the gates open or close in 2 minutes. However, there is a 27-sec acceleration ramp at the beginning of each cycle and a 15-sec deceleration ramp at the close of each cycle to protect the gate. Therefore, the maximum speed is about 2.2 in./sec.

Special features of the cylinders employed by each gate system are their Ceramax and CIMS (Ceramax Integrated Measuring System) technologies. Ceramax is a proprietary ceramic coating applied by a plasma spray process to each cylinder's rod to improve its corrosion resistance. CIMS consists of a sensor located in the head of the cylinder that detects grooves embedded in the base material of the piston rod. Evenly spaced grooves are machined in the carbon steel piston rod prior to the application of the Ceramax piston rod coating.

A magnetic field is created between a magnet contained in the sensor head and these grooves. Two half-bridged magnetoresistive elements located in this magnetic field produce sine and cosine signals, which are the input for a tracking phase resolver. The outputs of this resolver are quadrature incremental counting pulses that are converted to RS422A differential output pulses.

Advantages of CIMS include unlimited stroke length, accuracy, ease of interfacing, and the ability to replace or service while the cylinder is installed.

One condition for replacement of the old mechanical drives was that the new hydraulic cylinder assemblies had to conform to the original mounting pads on the miter gates and construction footprint on the concrete floor.

In control

On another application at the canal, hydraulics were supplied for several locomotive winch drives, which are used to safely guide ships through the locks by providing stable positioning to avoid accidental damage to the ships and the locks.

The specially designed and manufactured control system, including PLC, Ethernet, and fiber optics, has become the backbone of the complete lock operating machinery. The PLC-based control system communicates via fiber optic technology with a backup Ethernet link, all part of the central data system.

Previously, the control sequence used handles for each lock station. This required an operator to reach and manually turn handles until the lock was at the appropriate position. Now, with the hydraulic upgrade, the operator controls the lock from one station, eliminating the need to manually turn the control handles. As a result, less manpower is required in the control room. Operators can also monitor performance, allowing for maximum operating efficiency and streamlining data acquisition for preventive maintenance.

"The hydraulic technology has generally reduced the maintenance requirements, spare parts inventory, and operations downtime," said Carlos G. Patterson, Panama Canal project engineer program coordinator for the Locks Division. "It has also increased the level of technical knowledge among engineers and technicians."

Today, canal personnel can schedule maintenance, such as changing filter elements, during a regularly planned outage. This was not the case with the earlier, mechanical system. Furthermore, the hydraulic cylinders require virtually no regular maintenance.

To date, all 80 of the Panama Canal's miter gates are working well. Patterson adds, "Since the conversion to hydraulic technology, the canal has consistently improved its throughput. Although this is a result of a combination of several changes or improvements, the hydraulics technology has been an important contribution."

The Authority is currently working to upgrade vehicular gates by converting the old mechanical drives to hydraulic drives similar to those for the miter gates.

Janine Krempa is an applications engineer and Louis Prieto is a systems engineer with Bosch Rexroth's Hydraulics Div., Lehigh Valley, Pa. Email them at Janine.krempa@ boschrexroth-us.com or louis. [email protected]