Variety is their specialty

Hydraulic cylinders may be the workhorses of powerful mobile-and industrial hydraulic systems, but air cylinders come in a much wider array of specialty designs and configurations. This makes it a cinch to specify these unconventional cylinders into applications where even custom-made conventional cylinders don't fit the bill.

Like all cylinders, specialty cylinders use pressurized fluid (air, in this case) to produce linear motion-and force to move, position, or compress a load. They depart from convention in their configuration, design, construction, or even mode of operation.

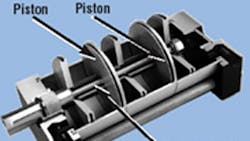

For example, a tandem cylinder uses two or more pistons connected to a single piston rod to multiply force produced by a cylinder without increasing bore size. This makes tandem cylinders ideal for applications where high force must be generated from a slender profile.

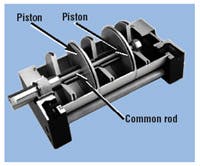

A duplex cylinder, however, contains two pistons connected to a separate, coaxial piston rod. This configuration can produce motion with two different stroke lengths. With both pistons retracted, one stroke is accomplished by energizing the cylinder chamber opposite the rod end. A second stroke occurs by energizing the chamber closed to the rod end. The net result is a cylinder that produces three distinct positions with having to use complicated switching or external stops.

Spare the rod

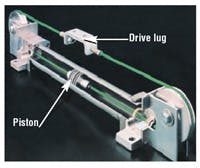

Probably the widest variety of designs occurs with rodless cylinders. As their name implies, these do away with the piston rod that normally protrudes from a cylinder's end cap. Because of this, they can produce the same stroke of a conventional design, but in roughly half the retracted length.

This brief overview introduces only a few of the variations of specialty pneumatic cylinders. For more comprehensive technical coverage, refer to the Fluid Power Basics section of our website at www.hydraulicspnematics.com. For a more complete sampling of the variety of specialty air cylinders available, associate editor Mary Gannon presents capsule descriptions in our Product Spotlight, beginning on page 54.