Huge cylinders help “thread a needle” 10,000 ft under water

Select for full image

Imagine yourself on a floating platform in the middle of the ocean. Your challenge is to thread a needle located almost two miles below you on the sea floor, only instead of thread you have to do it with a string of heavy steel pipe suspended under your platform.

That’s exactly the challenge faced every day by the people involved in finding and producing oil from subsea reservoirs in the Gulf of Mexico, the North Sea, off Nigeria, Brazil, and many other locations around the world. With the offshore frontier rapidly moving into depths of 10,000 ft and more, the challenge of designing and building equipment to support these operations becomes increasingly difficult and demanding.

Take, for example, the basic task of guiding the drill string from a platform to the “eye of the needle” at a wellhead 10,000 ft below. One answer is to run steel cables, or risers, between the two points and use them to guide the pipe — or anything else — that goes from the platform to the wellhead.

A tense situation

Making that work requires a relatively constant tension on the cables as the ocean’s waves move the platform up and down relative to the sea floor. Too high a tension, and the guidelines will snap. Too low, and the drill string will buckle from its own weight.

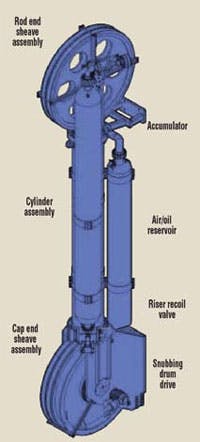

The popular solution is a device called a wire line riser-tensioner (WLRT), which uses a large hydraulic cylinder to adjust the distance between a pair of sheaves attached to the cylinder and rod and through which the guidelines are wound. By extending or retracting the rod to increase or decrease the distance between the sheaves, the cylinder can compensate for vertical platform movements of 50 ft or more while maintaining relatively constant loading on the guidelines. Double sheaves typically are used on each end to quadruple the amount of force imparted to the wire line by cylinder movement.

It’s all about the cylinder

Building cylinders with the required capacity and stroke that will operate reliably in the unforgiving environment of an offshore platform, meet the stringent requirements of various government maritime agencies, and conform to American Petroleum Institute standards is anything but simple. To add to the challenge, the cylinder systems must be as light and compact as possible to conserve valuable deck space and cargo capacity on the platform.

Eaton’s hydraulics plant at Eindhoven, Netherlands, has been a supplier of specialized cylinder/accumulator assemblies for WLRT cylinders for more than 12 years. More recently, Eaton’s Decatur, Ala. plant emerged as an additional manufacturing site for WLRT cylinder/accumulator assemblies for offshore platforms.

Eaton produces several sizes of WLRT cylinders, capable of providing between 200 kips (200,000 lbf) to 250 kips (250,000 lbf) of force each. The cylinders range in size from 18.5 in. (470 mm) bore with a 15.75 in. (400 mm) diameter rod, to 21.26 in. (540 mm) bore with an 18.9 in. (480 mm) diameter rod. Most WLRT designs have a stroke of around 150 in. (3.8 m), and weigh between 24,000 lb (10,886 kg), including 240 gal (909 l) of hydraulic fluid, to 28,000 lb (12,700 kg) with 305 gal (1155 l) of fluid.

The high-pressure portion of the cylinder system operates at 3000 psi. The low-pressure end is used only to provide fluid for lubrication and to keep the seals conditioned. “This is essentially a ‘push’ application,” says Eaton’s senior cylinder engineer Sudarshan Sharma, “so the relatively large rod size in relation to the cylinder bore is beneficial and does not adversely affect the cylinder performance.”

The cylinders are of welded construction with a welded-on cap on the high-pressure end. A welding system is designed to accommodate the large diameter, thick-walled tubes that become the cylinder barrel. “Once a weld procedure is qualified,” Sharma continues, “the system reproduces the weld with a high degree of repeatability. The critical operating parameters such as voltage, current, and heat input are keyed in before starting the weld. The operator monitors the weld and makes sure that there is enough wire and flux in the feeders, but unless some problem is encountered, the weld itself is done entirely by the machine.”

Sealing water-glycol

A non-flammable water-glycol fluid is used in most offshore platform applications. Therefore, seal materials must be chosen for compatibility as well as performance. Custom-designed seals made from advanced materials are used exclusively for both seals and guide rings.

Sharma explained, “The cylinders have to be highly responsive. Even if the commonly used urethane seals didn’t swell in contact with the water/glycol fluid, we would not use them because of their higher friction and propensity for generating stick-slip shock and increased system response time.”

The cylinder systems are equipped with anti-recoil valves to control rod acceleration in case of a cable break. The rod end also has a built-in cushion to aid in emergency deceleration. In use, the cylinders are never intended to traverse their full stroke. They are designed to handle the wave height of a 100-year storm, plus a safety factor.

Each assembly is also equipped with a safety relief valve on each end of the cylinder, plus drain and fluid addition valves for maintenance purposes. Because the cylinder-accumulator assemblies require no external fluid supply, the rod-end accumulator is nitrogen charged to provide pressurized fluid for lubrication, seal conditioning, and corrosion prevention.

Because they are deck-mounted, the cylinder-accumulator assemblies are not subject to intensive salt-water corrosion. Cylinders are protected with a three-part epoxy paint specified by the customer. Rods have a hard chrome-over-nickel plating.

“We are dealing with airborne salt spray only in this application,” Sharma explained. “For more difficult corrosive environments — such as those faced by direct-acting tensioners, which are mounted below the deck where the cylinder rods are constantly splashed by sea water — we also can provide more sophisticated coatings for both rods and cylinders, but they are not really justified for the wire line-tensioning assemblies.”

Since ramping up production, the Decatur plant has shipped cylinder-accumulator assemblies to shipyards in South Korea and Singapore. All of these will be installed on platforms now under construction and due to be launched in 2008.

For more information, visit www.eaton.com or e-mail sudarshan [email protected]