The Case for Electro-Hydraulic Actuators

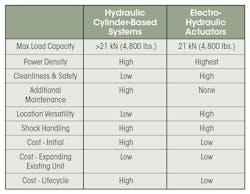

Hydraulic cylinders have long been engineers’ first choice for handling loads higher than 3,000 lb. But if space is tight, hydraulic cylinders and all their ancillary equipment can be difficult to shoehorn into a design, despite their power advantages. A more compact alternative are electro-hydraulic actuators. They can handle loads up to 4,800 lb and move them at up to 4 ips (inches per second). They are clean, versatile and have relatively low lifecycle costs. They also match hydraulic actuators in terms of handling loads and shocks. Electro-hydraulics are now used in a range of heavy load-handling applications in outdoor equipment, marine, military, aerospace and many other fields.

Hydraulic cylinders that convert electrical energy into motion require an assembly of oil reservoirs, electric motors, pumps, oil filters, relief valves and directional valves. The size of the pump and all the other components are determined by the target speed and cylinder size. So as speed requirements increase, the cost of whole set-up and its footprint also increase.

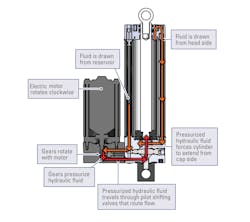

In an electro-hydraulic actuator an electric motor rotates clockwise, turning gears that pressurize the hydraulic fluid. Valves open to draw fluid from the reservoir and head side and also control delivery to extend the rod. For retraction, the motor runs counterclockwise, reversing the operation and returning fluid to the reservoir and the opposite side of the piston.

Although electro-hydraulic actuators and hydraulic cylinders may be similar in size, hydraulic cylinders require significantly more components. This gives electro-hydraulic designs a distinct advantage in power density.

Electro-hydraulic actuators also hold an advantage in cleanliness and safety. Hydraulic cylinders and their components can develop leaks at pipe and hose fittings due to vibration and other factors, pushing oil and fumes into the plant with every stroke. This pollutes the air and possibly creates slip hazards. Meanwhile leaks in the pump, pressure controls, directional valves and cylinder convert pressure and flow to heat or wasted energy, which reduces actuator speed.

Self-contained electro-hydraulic actuators require no maintenance. Hydraulic cylinders, on the other hand, require constant fluid servicing. And as they age, they begin to wear and leak around the piston. Pumps and other components also wear over time and develop internal leaks and pressure losses.

Engineers have more design flexibility when positioning electro-hydraulic actuators. They do not need elaborate support systems, so they can be more easily placed so that control is closer to the point of application and accessibility is also improved.

For example, it’s easier to run electrical wire than hydraulic lines up the boom of a cherry picker or run an electric cable from a tractor to a towed planter to control seed depth instead of hydraulic lines. In both cases, overall system size is reduced along with the risk of leaks.

Hydraulic cylinders are adept at handling sudden shocks, such as when a cylinder-guided plow hits a snow-covered barrier or a mower deck runs into a large rock. They absorb sudden energy spikes instantly by redistributing fluids throughout their internal valves and pump housing. Electro-hydraulic actuator shock resistance is on par with that of hydraulic cylinders.

Conventional hydraulic systems can be most cost effective when adding extra cylinders to a design that already contains other hydraulic elements. Otherwise, the cost of incorporating the necessary support system must be considered. Electro-hydraulic actuators eliminate fluid handling and storage, leak and spill management, and the additional maintenance costs of identifying and repairing leaks, which reduces lifecycle costs for end-users and provide benefits that OEMs can market to their customers.

Travis Gilmer is a product line specialist-for Thomson Industries, Inc.’s linear actuators.

About the Author

Travis Gilmer

Product line specialist, Thomson Industries, Inc.

Leaders relevant to this article: