Think First, Then Troubleshoot — Chapter 3: Use Your Senses to Begin Troubleshooting

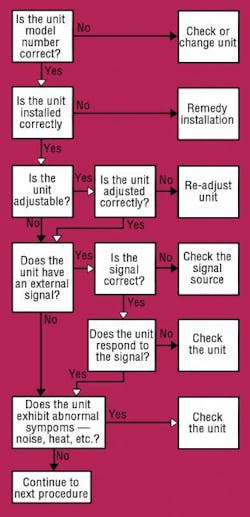

Unfortunately, many companies neglect or ignore the internal recordkeeping that is necessary to perform a logical troubleshooting sequence. It may seem foolish to review machine basics on equipment that has run for years, but in many cases, personal observation is the only way to determine operating parameters that can lead you to where problems originate. The Preliminary Checklist, Figure 2, can help you find problem sources that have nothing to do with the machine’s hydraulic system.

On the other hand, hydraulic systems may show signs of leakage or excessive heat, noise, or vibration without any adverse effect on machine performance — at least not at first. But these early signals should not be ignored. Continue your preliminary check by using the human senses of sight, touch, and hearing to identify and pinpoint the problem area.

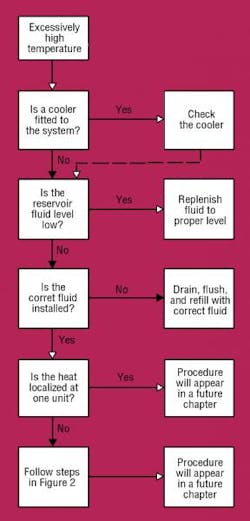

It is important to remember that a machine may exhibit abnormal symptoms because of a problem that might actually be present elsewhere in the system. For instance, pump cavitation or aeration might be taking place in a remotely located hydraulic power station. In such a case, the Fault Cause Remedy Checklist, Figure 3, should be followed to identify the problem source.

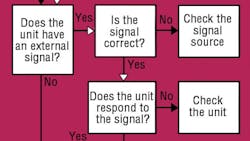

If a preliminary check does not find the problem, a more exhaustive examination, similar to the procedure suggested in the Machine Fault Checklist (Figure 1, from Chapter 2) must be conducted.

About the Author

Alan Hitchcox Blog

Editor in Chief

Alan joined Hydraulics & Pneumatics in 1987 with experience as a technical magazine editor and in industrial sales. He graduated with a BS in engineering technology from Franklin University and has also worked as a mechanic and service coordinator. He has taken technical courses in fluid power and electronic and digital control at the Milwaukee School of Engineering and the University of Wisconsin and has served on numerous industry committees.