Think First, Then Troubleshoot — Chapter 10: Sequence Valves

Chapter 10: Sequence Valves

In hydraulic systems, sequence valves control fluid flow to the primary and secondary circuits. A sequence valve performs two functions. First, it programs the order or sequence in which certain events take place. Second, it maintains a minimum predetermined pressure in the system’s primary line while preset events occur in the secondary circuit. The sequence valve’s maximum primary pressure setting should never be less than 200 psi below the setting of the system relief valve.

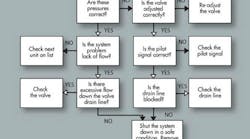

To troubleshoot a sequence valve, you will need to install pressure gauges in the valve’s primary and secondary ports at TP1 and TP2, Figure 13. Most valve manufacturers provide gauge ports in their sequence valve bodies. The pressure gauge readings provide the troubleshooter with the clues needed to understand what is happening within the sequence valve.

Contaminants in the hydraulic fluid can affect a sequence valve in two ways: by plugging internal pilot passages in the valves and by accelerating wear of all moving parts.

A sequence valve can malfunction in a variety of ways:

Premature valve shifting (low pressure readings on page at TP1). If oil flows from the primary to the secondary port at pressures below the original valve setting, check the sequence valve to determine whether:

- The drain hole through the main spool is plugged. This would allow pressure to build in the low end of the spool cavity, causing the spool to shift at the wrong time.

- The main spool is stuck open because the spool and/or bore are scored or bound with contaminants.

Delayed valve action (high pressure readings on gauge at TP1). If pressure in the primary port rises above the original valve setting, check the sequence valve to determine whether:

- The pilot control piston is binding. If so, is it due to scoring or contaminants that keep the main spool from shifting to direct fluid flow from the primary to the secondary port.

- The pilot fluid passage in the valve body is plugged with contaminants thus lowering the pilot pressure required to shift the spool.

Pressure fluctuations (gauges at TP1 and TP2 show erratic pressure changes) could be caused by:

- Changing contamination levels in the valve as contaminants periodically wash through.

- Or varying pressures in the valve drain line to tank. If this drain line is sized improperly, backpressures may fluctuate as other control functions cut in and out of the system.

No fluid flow from secondary port (no pressure at TP2). If the valve drain line is not connected to reservoir, but instead is open to atmosphere, backpressure will rise in the top cavity over the main spool – because of internal leakage – to a level where the main spool cannot shift.