Sensor monitors energy contained in accumulators

Hybrid hydraulic drives use accumulators to store kinetic energy from braking as hydraulic energy instead of braking a vehicle with friction. The hydraulic energy can then be used to accelerate the vehicle, which can substantially increase fuel economy. The greatest potential for energy savings lies with heavy vehicles that make frequent stops — delivery trucks, buses, garbage trucks, etc.

Optimizing hydraulic hybrid drives will require precise control of key elements, especially the system’s pumpmotor and accumulator. Because the accumulator acts as a storage device for the hydraulic energy, determining the amount of energy (charge) available in the accumulator at any given instant is essential for an optimized system.Pressure is not enough

For example, accumulator charge state data will allow the control software to “look ahead” to vary the contribution by the engine in order to maintain the proper power reserves during operation. Accurate charge data will also allow for full utilization of the accumulator charging range. Finally, having the ability to monitor accumulator charge state allows the system to quickly detect hydraulic fluid leaks that may occur.

Pressure transducers are commonly used to obtain approximate charge state data in accumulators. However, a major drawback to using pressure transducers is that for a given volume, the pressure of a gas varies significantly with changes in temperature. In addition, simply using pressure to determine charge state assumes that no leakage or changes in the gas charge occur.

The most direct method for determining the charge state of an accumulator is to measure the position of the piston inside the accumulator. Piston position is directly proportional to the available energy in the accumulator. Although this sounds simple, it can be difficult to find a position sensor that can be used inside an accumulator. Internal pressures in excess of 6000 psi; oil, either in the fluid state (on the oil side), or as entrained vapor (on the gas side); and various mechanical constraints combine to rule out most position sensors.

Accurate and reliable LVDTs

Any sensing technology being considered for use in hydraulic systems must be easily integrated, while simultaneously addressing the challenges outlined above. One such technology is the linear variable displacement transducer, or LVDT. The LVDT is an inductive (non-contacting) sensor that has a long history of success in specialized hydraulic and aerospace systems, including in servovalves and as spool position sensors. The LVDT is immune to pressure and fluid immersion, and its differential sensing method provides a good degree of rejection of common-mode disturbances, such as temperature shifts.

However, an important drawback of LVDTs is their relatively short measurement range. It’s not practical to directly measure a long linear translation with an LVDT. A solution to this problem is to use a coupling mechanism suitable for use in a hydraulic environment that extends the range of the LVDT. A sensor that embodies this approach is the SL720 linear position sensor, from Control Products Inc., East Hanover, N. J.

A long-stroke LVDT

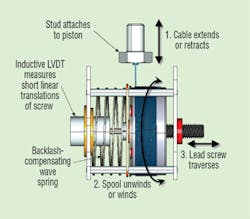

The SL720 uses a fine lead screw to couple an LVDT to a recoil spool. The recoil spool has a cable that is capable of extending up to 6 ft (1.8 m). When the spool rotates, it causes the screw thread to turn and produce a small linear translation that is read by the LVDT. In this way, the LVDT is coupled to the long translations of an object such as a piston in an accumulator, producing accurate absolute measurement of piston motion and position.

The SL720 can be used in either the gas side or the oil side of an accumulator. This key point fulfills the requirement for minimal design impact. The SL720 also has a high-pressure electronics connector with integral signal conditioning that solves the problem of conducting electrical signals into and out of the pressure environment. The recoil spool approach provides some other advantages. For example, the sensor’s range does not need to be matched to the specific travel requirement of a particular application. The SL720 covers any stroke up to 72 in. and the cable coupling tolerates some misalignment. This presents some new opportunities, such as integrating a linear sensor with a bladder-type accumulator or a telescoping cylinder.

For more information on the SL720 accumulator charge sensor, visit www.cpi-nj.com/accumulators.htm, call (973) 887-9400, or e-mail: [email protected].