In their mission of keeping the lights on for businesses and consumers alike, utilities have to contend with extreme, unpredictable weather events and natural disasters, while also keeping up with run-of-the-mill maintenance and vegetation management. Historically much of the infrastructure on the electric grid was allowed to run until failure. But today, with the risk of wildfire and the impact communities face when going without power during winter-storm events, utilities have shifted to preventative maintenance. Their goal is to inspect their entire systems more frequently, even when highly trained and experienced employees are harder to find and keep.

As utilities strive for greater reliability and resilience, they turn to robots to transform how they monitor and manage certain facilities. In fact, robots equipped with advanced sensors and cameras are becoming vital tools in electrical substations, enabling utilities to inspect their facilities more frequently, respond quickly to problems, access information during critical events and identify changing conditions that may be a precursor to catastrophic events failures.

Introducing Robots to the Substation

Utilities face unique and ever-changing challenges managing and maintaining the grid. Equipment is exposed to all types of environmental conditions. And it's located in diverse geography–from dense urban sites to remote locations that can be hours apart.

Electrical substations are a key component of the grid. These switching stations maintain the connections between transmission and distribution infrastructure, stepping down the transmission voltages, which can be hundreds of thousands of volts, to typically less than 10,000 volts for distribution to homes and businesses.

Substations contain a variety of highly engineered components—such as power lines, switches, transformers and circuit breakers—many of which may have been installed decades ago and are continually exposed to the elements. Since they are often situated in remote locations, it's not practical or possible to have employees on-site to monitor conditions or performance constantly. Many times problems are not discovered until it's too late.

That's where robots come in. Robotic platforms can be equipped with various sensors and cameras and be programmed to move around the substation or driven on-demand. On its rounds, the robot can monitor components' conditions and temperatures; identify anything out of the ordinary, like a broken tree limb that has landed on equipment, vegetation overgrowth or damaged security fencing; and alert managers to changes that may require attention. If an alert is received, operators can immediately have eyes on the situation rather than drive several hours to the substation to gather critical intelligence.

Putting Robots to Work

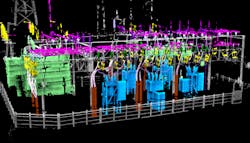

Select utilities implement programs that rely on mobile robotic platforms equipped with custom sensor stacks. These sensors can include a lidar scanner, near-infrared (NIR) and thermal cameras, and real-time kinematic positioning (RTK) GPS antennas. But, before these robots can be put into action, some preparation is necessary.

The robotic system needs to stand up to the harsh conditions of life in a substation. Dust and rain have the potential to shorten the lifespan of axles, pan-and-tilt camera units, or other sensor systems, so IP rating is critical. Even if IP rated, the system should not be exposed to the elements 24/7, so some sort of locking enclosure is necessary. Enclosures not only provide protection, but are where the system can recharge its battery and upload data from the day's inspection.

Most importantly, utility personnel need to be trained and available to utilize the system. Substation robots provide little value if they are left in the tool belt like any tool. But by adding a layer of automation to the data-collection aspect of substation inspection or having less experienced staff take on this sometimes tedious aspect of the work, experienced engineers and substation managers can focus their skills on correcting identified problems. This helps utilities scale their operations, inspecting equipment more frequently and quickly than ever before.

Once these elements are in place, the robot can be launched and gather data about substation and equipment conditions, minute-by-minute or on a daily, weekly or less frequent basis. The sensors and cameras onboard enable it to acquire 2D and 3D views of the station, note any measurable changes, and make observations similar to a human inspector's. The robot can also detect and identify physical and spectral changes, leaks of liquid or gas, or objects, such as animals or people. that should not be in the facility, and monitor for thermal changes and corrosion.

Improving Operational Insights

Substation robots generate operational information at previously unattainable levels, enhancing regular inspection activities, improving proactive maintenance and enabling faster response to unexpected events. A few of the ways they're transforming substation management include:

- Thermal monitoring in aging distribution stations can capture equipment degradation, allowing replacements to be made before failure.

- Events like hurricanes, winter storms and wildfires can generate outage conditions without warning. The robot can traverse the substation to see what equipment has been impacted, eliminating the need for an in-person inspection and shortening repair response time.

- Roving cameras in the robot can improve security and change detection, combating intrusion by animals and people in an automated way that conventional security cameras cannot capture. Two-way communication allows security personnel to engage with would-be trespassers.

Increased use of robots, combined with sophisticated analytics, artificial intelligence and machine learning, have the power to create a new connection between data and operations. This could include informing the lineman about the exact location and damage caused by hurricane-force winds and falling branches. Linemen then could have the correct replacement equipment and quickly respond to restore power. Use of robotics also could give utility managers a deeper understanding of signs of imminent equipment failure, allowing them to repair components to avert outages proactively. Or it could result in other new insights that ensure utility can leverage the best information to achieve greater reliability and resilience.

This article was written and contributed by Ian Berdie, vice president of Innovation, NV5 Geospatial

About the author

Ian Berdie is the vice president of Innovation for NV5 Geospatial. He earned a B.A. from Carleton College and an M.A. in Geography and Remote Sensing from the University of Miami. Prior to his time at NV5, he worked as a wildlife biologist for various state agencies and nonprofits.

About the Author

Ian Berdie

Vice President of Innovation, NV5 Geospatial

Ian Berdie is the vice president of Innovation for NV5 Geospatial. He earned a B.A. from Carleton College and an M.A. in Geography and Remote Sensing from the University of Miami. Prior to his time at NV5, he worked as a wildlife biologist for various state agencies and nonprofits.

Leaders relevant to this article: