Pneumatic Conveying Systems to be Driven by Innovative Designs

Pneumatic conveying systems have continually emerged as a cost-effective and practical way to convey bulk materials. Substantial development had expanded the technology to where even high-density materials can be conveniently conveyed using these systems. With numerous benefits over the conventional conveying system, these systems stand in a position where they can be an efficient substitute for chain belt and chain conveying systems in several applications. Plus, rapid industrialization and availability of energy-efficient products also plays a key role in driving the growth of the global pneumatic conveying system market.

Top Trends in Pneumatic Conveying Systems

Our research indicates that the global pneumatic conveying system market size is expected to reach in excess of $36.4 million by 2025, growing at a compound annual growth rate of more than 5% from 2018 to 2025. Development of application-specific and customized products, advancements in more-compact pressure vessels, and incorporation of smart controls some of the key factors expected to drive the global demand over the forecast period.

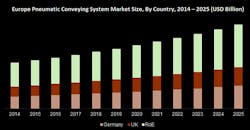

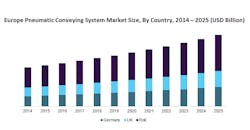

The figure below depicts the pneumatic conveying system market estimates and forecasts in Europe. The region is expected to emerge as the dominant one, accounting for more than 30% of the total market share over the forecast period. This may be attributed to increasing government regulations to use better sanitary operations. Additionally, the presence of various regulatory bodies in the region providing mandates for the use of pneumatic equipment may also contribute significantly to regional growth.

1. European pneumatic conveying system market size by country, 2014 to 2025, in billions USD. (Source: Grand View Research)

Asia Pacific is expected to exhibit high growth over the coming years from rapid industrialization and development in the region. Growing health and safety concerns have also spurred manufacturers to use pneumatic equipment due to its better hygiene and lower susceptibility to end-product contamination.

Adoption of higher-pressure systems has significantly improved the air quantity used for conveying products or materials over the long distance. The use of constant mass air flow with positive pressure conveying system prevents plugging while minimizing abrasion, power consumption, and maintenance costs.

The emergence of positive-pressure systems has reduced sensitivity to pneumatic material flow characteristics, which allows the system to convey large and dense particles. Pressure systems can also convey material when the conveying pipeline is curved or bent, which can reduce the surface area of the system’s conduit. Thus, these systems are widely used in the material handling and conveying market.

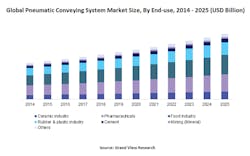

2. Global pneumatic conveying system market size by end use, 2014 to 2025, in billions USD. (Source: Grand View Research)

Rising Adoption Across End-Use Industries

Pneumatic conveyors offer many benefits over conventional systems, such as lower production downtime, higher productivity, better retention of product quality, and lower cost. These benefits drive growth across such end-use industries as food processing, pharmaceutical, ceramic, and rubber and plastics. As a result, companies are investing considerably to step up their production capacities to meet increasing demand. In addition, these companies are working toward installing advanced process handlers and equipment, such as pneumatic conveyor systems, to reach the optimal process efficiency.

Product contamination and dust-free products are the major critical issues for these industries. Conventional conveyors allow many dust particles and foreign particles to enter the system and damage the material quality, resulting in huge losses and wasted raw material. Many companies are installing pneumatic conveyors to avoid these losses, to keep foreign particles or dust from entering the system, and to ensure high product quality and safety throughout the entire conveying process.

- Growth across the construction industry is projected to spur the pneumatic conveying systems demand in the ceramic industry. The construction sector is the chief employer of inorganic and non-metallic ceramic materials, thereby driving the ceramic demand and, in turn, fueling growth for pneumatic conveying systems.

- Several benefits over conventional conveyors are offered by pneumatic conveying systems in the food processing industry, such as higher reliability, smaller system footprint, lower operational costs, greater productivity, lower risk of material spillage, lower maintenance costs, and greater versatility in system design. These benefits are all expected to drive market demand upward.

- The rubber and plastics industry is expected to exhibit high growth over the forecast period. This may be attributed to more widespread use of pneumatic conveying systems for reducing dust generation and streamers, along with decreasing investment.

- The ceramics industry is also estimated to undergo substantial growth from increasing use of pneumatic conveying systems for automating all types of powder and granular material processes.

- Increasing demand for powder transfer via vacuum in the pharmaceuticals industry is estimated to propel industry growth significantly over the forecast period. The inherent ability of pneumatic equipment to keep powder contained within the system is expected to elevate product demand. In addition, increasing use of specially designed pneumatic equipment for refill operations for continuous pharmaceutical processes—such as continuous granulation, blending, mixing, and extrusion—may also boost demand.

Greater Automation in Material Handling

Material-handling equipment encompasses a huge assortment of products used for the storage and transportation of raw materials and other goods. Equipment such as storage-and-retrieval systems and lift trucks streamline the supply chain distribution channel and enhance the operational efficiency and workflow in production processes. Their use also improves utilization resources.

Manufacturing industries continue a strong trend toward automation, resulting in greater demand for industrial robots’ technical enhancements of them. Robotic systems help prevent injury to personnel, reduce labor cost, and offer a high return on investment. A shift toward automation offers producers a host of benefits, such as greater speed and accuracy of production, more-consistent quality, and reallocation of skilled workers to other zones of the production processes. The advent of new equipment, technologies, and systems has fundamentally changed the way several manufacturing industries function.

Automated material-handling equipment, such as automated guided vehicles, automated conveyors, and robotic systems, combine to increase the throughput of suppliers and manufacturers. They also aid in the computerized control of received assembled parts, just-in-time delivery of raw materials, and tracking of materials within a facility.

The growing automation and technological advancements have made manufacturing units in developed countries fully automated. The automated material handling market is driven by improved wireless technology, predominantly in automated guided vehicles. For instance, Seegrid's vision-guided AGV uses navigation sensors to create a 3D map of the production facility, enabling the vehicle to follow a pre-computerized route without any human intervention.

Technological Developments

Technological advancements and development of several feeding technologies—such as suction nozzles and hoppers, vibrating dosing screws, and rotary valves—present opportunities for high market growth. Further, development of new production technologies has given led to the use of blow-through valves, drop-through valves, and high pressure air-locks with improved precision, with the aim to reduce any air leakage.

The introduction of compact pressure vessel conveying systems integrated with intelligent control technologies provides another avenue for growth. Incorporating new materials in manufacturing pneumatic conveyors enables products to be conveyed more reliably than ever. New filter materials and designs allow continuous conveying of powders without compromising the filter capacity, which is further anticipated to drive demand over the forecast period.

Current Challenges and Future Opportunities

Despite the many advantages offered by pneumatic conveying systems, many companies still use conventional material-handling technology. This is due primarily to huge initial investments required for replacing conventional conveyors with pneumatic ones. Pneumatic conveying systems are expensive because of the high cost of a compressor or blower, pressure-tested and larger-diameter pipelines, and large dust collection systems. The development of more-innovative products—such as suction hoppers, suction nozzles, vibrating dosing screws, and rotary valves—should lead the industry to considerable growth over the next few years.

According to the report by Grand View Research the global market size will witness a growth at a CAGR exceeding 5% from 2018 to 2025. In terms of regional growth, Asia Pacific will grow at the highest CAGR, exceeding 6% over the forecast period. Europe accounted for the highest market share in 2017, owing to growing demand for hygienic methods in the product transfer and production. The regional growth will be led by increased demand across the food industry, owing to several regulations that govern the sector.

Shruti Palod is a research analyst at Grand View Research, San Francisco. She has published multiple research studies under the ICT domain.

About the Author

Shruti Palod

Research Analyst

Leaders relevant to this article: