This file type includes high resolution graphics and schematics when applicable.

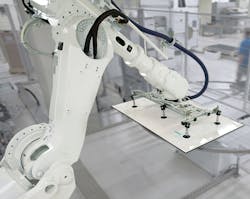

Industry 4.0, often referred to as the Internet of Things (IoT), is being called the fourth Industrial Revolution. It predicts a world where countless “smart” machines and devices embedded with electronics, software, sensors, and communication capabilities are networked to each other, creating the so-called intelligent factory.

Such devices will acquire data and share it with manufacturers, users, machines, and other connected devices. And harnessing that data will let OEMs run equipment and processes faster and more efficiently, respond quicker to changing product demands, maximize reliability via predictive maintenance, use resources more efficiently, and permit real-time optimization of overall manufacturing operations.

Vacuum and Industry 4.0

Vacuum specialist J. Schmalz GmbH, based in Glatten, Germany, is embracing the transition to Industry 4.0. The company manufactures a wide range of vacuum components and systems that make handling, clamping, and gripping processes more productive, efficient, and flexible—and increasingly suited for the intelligent factory.

In fact, Schmalz launched a vacuum generator with an IO-Link interface back in 2008, long before the subject of Industry 4.0 became widely known. The company is also said to be the first vacuum-products manufacturer to combine sensor and actuator functions in Industry 4.0-compatible devices.

According to Managing Directors Kurt and Wolfgang Schmalz, companies competing at an international level can’t afford to ignore Industry 4.0. Manufacturers need to prepare for networked production so people, machines, and systems can seamlessly interact.

Among the potential benefits for OEMs, they say, is equipment that can quickly adapt to product or process changes, yet is highly productive and efficient. It permits both high-volume production and product individualization—resulting, for instance, in cost-effective batch sizes as small as a single product. Networking will ensure these increasingly complex production processes become more manageable.

As an example, Schmalz produces an intelligent vacuum generator called the X-Pump compact ejector that facilitates real-time communication and networking. The X-Pump gathers and stores process data, making it available to other devices and systems on the network; in return, it receives configuration and optimization commands. Its diagnostic and prediction functions monitor system conditions—such as wear or contamination—and detect gradual changes, as well as imminent malfunctions. This lets manufacturers avoid unplanned machine downtime and increases system availability.

This kind of automation networking moves beyond traditional, rigid, hierarchical information structures. In today’s conventional plants, field-level sensors and actuators typically transmit data to control-level devices such as programmable logic controllers. The PLCs, in turn, send information on to process-management level devices such as human-machine interfaces (HMIs), plant-level manufacturing-execution systems (MES) and, ultimately, enterprise-level enterprise resource planning (ERP) systems.

With Industry 4.0, in contrast, an automation “cloud” lets intelligent devices interact seamlessly with one another. Via IO-Link, it is possible to track information such as vacuum level, whether the workpiece is gripped, and cycle times of intelligent field devices. HMIs handle parameter entries such as time and speed, and measure outputs like energy consumption; MES tracks productivity and quality data and notes maintenance requirements; and ERP monitors overall capacity and availability for operation planning.

IO-Link Explained |

|

“Smart” field devices from Schmalz, such as the X-pump, use IO-Link as the interface for communication in all standard fieldbus systems. IO-Link is a powerful, standard (IEC 61131), point-to-point serial communication protocol used to transfer information—process data, service data, and events—between sensors or actuators and other devices. It provides significantly more information and control capacity than that from simple devices like digital or analog sensors. Two bytes of process data can be transmitted per cycle between an IO-Link master and device at 400 μsec speeds and 230 kBaud. More process data can be sent at correspondingly slower speeds. Standard cables and connectors reduce wiring complexity. Connection is via a three-wire cable, usually with M12 connectors. IO-Link’s parameterization capabilities simplify device configuration through standard network interfaces. For example, process operation profiles or instructions can be remotely downloaded to compact ejectors to adjust vacuum gripping action on the fly. In theory, different profiles can be called up for each individual cycle. At the same time, the gripper communicates with the higher-level controller and provides complete condition data. This not only allows continuous monitoring but also comprehensive process control, which in turn means ongoing process optimization. Thus, remote configuration via IO-Link minimizes set-up times and downtime. In contrast, processes that rely on more-conventional devices can face long changeover times. Machines must be stopped, components changed or manually reset, and operations tested and tweaked before the machine is again up and working. Downtime can be significant and costly. |

Smart Field Devices

Schmalz offers a number of IO-Link devices capable of communicating with other components, controllers, and systems. These smart field devices represent the “i” series and include vacuum generators as well as SNGi-AE needle grippers. They gather, interpret, and transmit process data using IO-Link. All of the i-series products perform higher-level “intelligent” functions such as energy monitoring, condition monitoring, and predictive maintenance.

SCPSi compact ejectors are suited for applications that need space-saving and energy-efficient vacuum generation in quick pick-and-place applications. They’re typically used for fully automated small-parts handling. They have high-efficiency nozzles and produce suction rates up to 69 l/min.

SCPi/SMPi compact ejectors are suited for handling suction-tight and slightly porous workpieces. They’re used for pick-and-place applications with extremely short cycle times, have suction rates up to 185 l/min, and offer optional power blow-off for quicker release of the workpiece.

SXPi-PC/SXMPi-PC compact ejectors, featuring an integrated pressure sensor, are for handling air-tight workpieces under extreme conditions. The devices are typically installed in press lines for sheet-metal production. The ejectors are extremely robust and offer suction rates to 220 l/min. Optional power blow-off is also available.

In addition to these pneumatic products, the company also offers the SNGi-AE electric needle grippers for handling textiles and other non-rigid and highly porous materials. Needle stroke can be changed for each cycle, with definable process profiles. A pneumatic-powered, manually adjustable version (SNG-AP) also is available.

System Benefits

These networked field devices offer comprehensive energy and process-control benefits, such as:

Energy monitoring. The ejectors help optimize energy consumption in vacuum systems. In addition to capturing current energy consumption values, they set up vacuum-system parameters to maximize energy efficiency during operations. They have the ability to help provide trend analysis data per component, per production cycle, and per shift. And they can instantly identify excessive or unusual energy-consumption patterns. Data can be displayed via the system controller.

Condition monitoring. Diagnostic and condition-monitoring functions help maximize system availability. Continual monitoring of process parameters – such as operating pressure and leaks and for ejectors, or stroke and cycle times for needle grippers – provides a detailed analysis of system conditions and quickly detects errors. Fast and efficient troubleshooting of individual components or the overall system minimizes downtime and cuts costs.

Predictive maintenance. Predictive-maintenance capabilities improve gripper performance and increase the overall quality of gripping systems. For instance, the system can measure flow resistance and leak tightness in grippers, evaluate overall performance, and permit quick and straightforward circuit optimization. It also can identify and prevent faulty configurations. Finally, it can monitor performance-relevant process data and quickly recognize changes in system conditions due to issues like leaks or contamination.

Sizable Savings

As one example of the possible savings from using smart vacuum devices, consider an automotive press line that makes car body parts. The automated handling equipment is designed to efficiently transfer components between presses with minimal cycle times.

This potential application uses X-Pump SXMPi-PC compact ejectors with integrated energy- and process-control capabilities. It helps monitor and analyze all critical process parameters, including energy consumption and system conditions, and offers predictive-maintenance functions. IO-Link provides the interface for bidirectional communication with higher-level systems.

The X-Pump permits simple and fast system set-up, identifies and prevents incorrect tooling configurations, significantly reduces energy consumption, and helps optimize overall process performance.

Most significantly, the compact ejectors increase up-time for automated sheet-metal parts handling operations. They constantly monitor tooling condition, detect subtle changes or impending failures, and report them to the system controller. Early error detection lets users establish a planned, preventive maintenance program before a machine fails and the line shuts down. Cost savings would depend on the failure cost in a specific automotive plant. But in a typical plant, just reducing downtime by one minute per day can generate annual savings of up to 300,000 Euro.

Justin Katz is an Application Engineer at Schmalz Inc., Raleigh, N.C. For more information, call (919) 713-0880, or visit us.schmalz.com.

Near-Field Communcations

In another step toward the intelligent factory, Schmalz introduced its new SCTMi Compact Terminal at the Hannover Fair 2015. Its integrated near-field communication (NFC) permits data exchange between devices over short distances. For example, a user can hold an NFC-enabled smartphone directly at the terminal’s NFC icon and immediately receive important data in the phone’s browser. It transfers a range of information, including terminal identification, parameterization (basic and process settings, such as switching points), error messages and diagnostics, and the device’s operating manual. Time-consuming visualization at the controller is, therefore, unnecessary.

The terminal holds up to 16 block-mounted, intelligent compact ejectors (vacuum generators). That means up to 16 different vacuum circuits can be individually actuated and monitored, which significantly expands the range of possible applications. The new compact terminal is instrumental in meeting the ever-increasing demand for more flexibility—particularly from the automotive industry—and helping engineers address the challenge of developing universal grippers for handling different types of goods.

Each ejector has energy and process control capabilities and provides important data to higher-level devices for handling-system configuration, optimization, and maintenance. For example, users can quickly detect error messages and initiate maintenance activities before a machine or tooling suffers expensive damage.

A single line supplies compressed air to the ejectors, and the terminal connects to a fieldbus system via the Ethernet or IO-link using a single electrical cable. In the near future, Schmalz plans to introduce additional NFC-equipped products.

This file type includes high resolution graphics and schematics when applicable.

About the Author

Leaders relevant to this article: