What’s the Difference Between Single-Stage and Multi-Stage Vacuum Pumps?

Single-stage and multi-stage vacuum pumps have been around for quite some time, but some designers and engineers remain unsure about when to use one versus the other. For example, which pump is best for pick-and-place applications with large objects? Is one a better option for end-of-arm tooling? What about for evacuating tanks, bottles or drums? Or processes such as box-carton folding and handling? How about clamping and holding during bottle-filling operations?

The best choices depend on variables such as dirt tolerance; costs to reduce clogging; actions needed to regain lost suction; and vacuum level, flow and speed requirements. They are also affected by the size, shape and material of the object being lifted, as well as by the application for which the vacuum pump is being used. For example, semiconductor applications, medical industries, material handling in manufacturing processes, manufacturing lines and vacuum pumps used on robots may all have different vacuum pump requirements.

Which pump type is better? Under what circumstances? Let’s take a deeper dive into vacuum and see:

Venturi Vacuum

Vacuum is used to hold things in place or move them from one place to another. When air is removed from an enclosure, the pump creates a pressure differential between the enclosure and the surroundings. This pressure change at the surface of a vacuum cup and workpiece forces the two pieces together. That force is determined by the interface area between the cup, workpiece and vacuum level. In other words, vacuum technology uses the surrounding atmosphere to create force and pull on a workpiece. The vacuum itself exerts no force; the air outside of the container exerts the force.

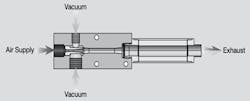

Venturi vacuum pumps use compressed air to draw the gasses—along with any debris, dirt or dust—out of the chamber. The gas and its particulates are all pulled into the pump.

In the venturi, compressed air passes through a nozzle that accelerates the air. As the air leaves the nozzle, it expands and increases velocity before it diffuses. This movement creates vacuum at the vacuum inlet port between the nozzle and diffuser, letting the nozzle and diffuser combine into a venturi vacuum cartridge.

Single-Stage vs. Multi-Stage

Single-stage venturi vacuum pumps with cartridges:

- Have “straight-through” designs that let dirt, dust and debris pass through without clogging the pump.

- Have no moving parts, so they better resist contamination associated with dirt and debris, thus ensuring a longer operational life.

- Generate higher flow rates and vacuum levels (above 18 in. of Hg), which translate into fewer missed picks for pick-and-place applications.

- Work best for operations that require a larger vacuum flow at higher vacuum levels (above 12 in. of Hg).

The downside of single-stage venturi vacuum pumps is that they require greater financial investments upfront and consume more air when matching evacuation times or flow levels at lower vacuums. Single-stage pumps are therefore recommended for operations where dust and dirt are present as in bakeries or to handle cardboard boxes.

Multi-stage venturi vacuum pumps feature:

- Filters to prevent the pump from clogging.

- Lower upfront costs.

- Greater flow rates with less air consumption at lower vacuum levels less 12 in. of Hg, making them ideal for applications where speed is critical.

- Higher initial flow rates that let pick-and-place machines move faster to save time.

The downside to multi-stage vacuum pumps is that they are not as effective as single-stage pumps for picking up heavier, porous objects. They are also prone to clogging in contaminated surroundings, so there’s more filter- and screen-related maintenance, and this downtime increases as the pump size increases. So, while upfront costs are lower, lifetime costs are higher than those for single-stage pumps due to the extra expenses associated with filters and screens.

Multi-stage vacuum pumps are recommended in clean environments or in applications where speed is critical from the outset, such as medical processes and in making silicon.

Choosing the right pump requires judgment, best practices and knowledge of the application factors such as costs, efficiencies, how much dirt can be tolerated, potential downtime that is acceptable, and the speed and vacuum flow needed.

After reviewing the differences between single-stage and multi-stage vacuum pumps, designers should also take into consideration the following which might narrow the choices:

- Multi-stage vacuum pumps offer performance advantages over single-stage pumps. At zero to 12 in. of mercury, multi-stage pumps remove air more quickly. With greater vacuum flow rates when matching air consumption, parts can be picked up and moved more quickly. However, this advantage goes away once the pump goes above 12 in. of mercury.

- At this level, single-stage pumps typically provide higher flow rates compared to similarly sized multi-stage pumps.

- If speed is critical and the application only needs lower vacuum because parts are light, a multi-stage pump can handle the job. Similar to flow rates, higher vacuum levels reduce the advantage of multi-stage pumps. As the vacuum level increases, single-stage pumps will surpass multi-stage pumps when it comes to efficiency.

- The weight of the object that must be moved should also be considered. Lightweight robots such as SCARA and Delta styles are designed to be operated with quick cycle times. Lower vacuum levels can handle these applications, so multi-stage pumps are the best choice. If the goal is to move heavy or porous objects, single-stage pumps are the better option.

Jeremy King is product manager for vacuum and sensing at Bimba, part of IMI Precision Engineering.

Vacuum Pumps Can Be Used For:

Industrial and scientific processes such as:

- Composite plastic molding

- Making electric lamps, vacuum tubes and cathode ray tubes

- Semiconductor processing

- Medical processes that call for suction or uranium enrichment

- Medical applications such as radiotherapy or radiosurgery

- Analytical instruments

- Mass spectrometers

- Milking machines

- Sewage systems

Mechanical devices including:

- Hybrid and diesel engines

- Gasoline engines

- Hydraulic brakes

- Ventilation systems

- Flight instruments

Industrial and scientific processes such as:

- Composite plastic molding

- Making electric lamps, vacuum tubes and cathode ray tubes

- Semiconductor processing

- Medical processes that call for suction or uranium enrichment

- Medical applications such as radiotherapy or radiosurgery

- Analytical instruments

- Mass spectrometers

- Milking machines

- Sewage systems

About the Author

Jeremy King

Product Manager, Vacuum and Sensing, Bimba

Leaders relevant to this article: