Troubleshooting Challenge: Press Mold Moving When It Shouldn’t

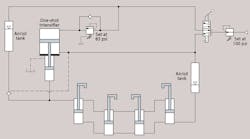

A company that molds nonmetallic airplane propellers loads both halves of a mold in a vertical press. It shifts an air valve that retracts 4-clamp down cylinders to hold the bottom half of the mold to the base plate and attach the top half to a large hydraulic ram that opens and closes the top of the mold. Both mold halves are heated, and the cure time runs 1 to 2 hours per part.

Every so often, when operators started to open the mold, the bottom half would move a little as if it was not being held down with enough force. Each time this happened they could not find any problem on the next several cycles. The maintenance crew decided to increase pressure on the inlet regulator. The intent was to increase the force on the hold-down clamps to fix the problem, but it didn’t. They replaced the pilot-operated check valve, thinking it must be leaking. However, the occasional problem persisted, resulting in scrapped parts.

Any idea why the hold-down clamps didn’t always do their job?

Find the Solution

Think you know the answer to this month’s problem? Submit your solution by emailing [email protected]. All correct answers submitted by Oct. 16, 2019 will be entered into a random drawing for a $50 gift card. The winner will be notified, and his or her name will be printed in a future issue. Only one gift card will be awarded to any participant within a calendar year.

Congratulations to Richard Throop, of Fenton, Mich., whose name was chosen from those who correctly answered last month’s challenge. A $50 gift card was mailed to him.

Solution to Last Month’s Challenge:

Multi-tonnage Pressure Problem

When inspecting the directional valve, the service technician found that a valve with a closed transition position had been installed instead of an open type. When the operator manually shifted the valve, the machine did did not fully shift to the next position. The transition position blocked all three of the relief tank’s drains for the pilot, which disabled the main relief function and caused the pump to explode. He also found a steel chip partially blocking the feed orifice in the main relief spool causing the low-pressure problem.

About the Author

Robert Sheaf

President

Robert J. Sheaf Jr., is the founder and president of CFC Industrial Training, formerly Certified Fluid Consultants, part of CFC-Solar Inc. CFC-Solar provides technical training, consulting, and field services to any industry using fluid power technology.

Leaders relevant to this article: