Long before people started talking about going green, sugar cane processing stood out as an industry that produces more energy than it consumes. The process involves running raw stalks of cane through a mill, where juice is squeezed out. The juice is heated to a temperature to drive out moisture and crystallize the sugar, and the spent stalks are burned to produce energy. Lots of energy — so much so that sugar cane mills generally produce more electricity than they use, so it’s not uncommon for electricity to be sold back to the local power company.

So you might think that using energy-efficient drives is not a priority at sugar cane mills. Not so. The less energy expended in producing sugar, the more energy that can be sold back to the power company. Therefore, when officials at India’s Mawana Sugars Ltd. looked a into new production line, they wanted it to not only yield more juice from the cane, but use less energy in the process.

Hydraulics satisfies demands

The drive that squeezes the juice out of the cane consumes more energy than any other portion of the mill. High torque and automatic speed control are essential to operate the drive at a speed slow enough to extract the most juice from the cane, but fast enough to avoid slowing production.

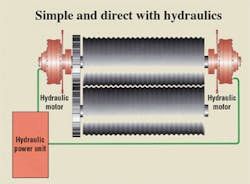

Many existing sugar mills — especially older ones — use a dc motor or steam turbine driving a multi-stage gear box to power the mill. This is where officials looked for improvement. They discovered that a direct-drive hydraulic system could achieve the tight speed control they needed while also using less energy than the gearbox and dc motor or turbine combination. The hydraulic drive is also more compact and has much fewer components. Not surprisingly, hydraulic mill drives have become increasingly common in sugar mills around the world.

Norland Suzor, of Hägglunds India, introduced Mawana Sugars officials to the concept of a driving system without gearboxes and combined with automated process control. Officials also stipulated that a single supplier assume full responsibility for both process control and driving systems. After meticulous investigation and examination of reference installations, company officials decided on a drive system from Hägglunds Drives, Mellansel, Sweden. The plant’s former director remarked, “Given the stated requirements, Hägglunds Drives presented a fully automated, hydraulic driving system without gears, which when compared to a conventional system proved to have even more benefits than we anticipated.”

Capacity and Investment Flexibility

The maximum design capacity of the milling plant was 7500 tons of cane per day, but the drive system conservatively designed for 5000 ton/day. However, capacity can be increased simply by installing additional hydraulic motors as required.

“The driving system’s flexibility makes it possible to invest at an acceptable pace, without scrapping or replacing older equipment, while at the same time retaining high performance,” the director remarked.

Control and efficiency

Despite the well-known fact that slower milling speeds result in high sugar juice yield, it was common practice at sugar plants in India, and most other sugar-producing countries, to set mill speed manually. Consequently, the mills run most of the time at fixed speeds with the resulting loss of productivity. Therefore, one of the requirements was that the speed of each mill could be independently regulated so that at any given moment the speed was as low as possible to prevent stoppages from overloading or jamming. Hägglunds Drives fulfilled this requirement with a programmable system that monitors milling loads and instantly adjusts the speed.

Several factors contribute to the lower energy consumption compared to geared systems. The hydraulic drive is connected directly to roller shafts, thereby eliminating the energy loss through gear drives. Furthermore, electrohydraulic controls automatically set the drive to the lowest appropriate speed. Because power required of the drive is almost directly proportional to the speed, a conventional turbine drive wastes energy by running at a virtually constant speed. Additional energy savings is realized when the mill operates at reduced capacity by shutting down one of the two hydraulic pumps powering the system.

Other benefits

The absence of bulky gears means the mill house can be just 20-m wide, as opposed to the traditional 24-m width. In addition, the gear drives require much larger foundations, so the smaller, lighter hydraulic motor drives also reduce installation cost.

The need for employees to continuously monitor and maintain conventional drive systems is virtually eliminated. Sudden gear tooth breakdowns are a thing of the past and the risk of shaft failure has been eliminated. Plus, there are no gear bearings to overheat, thanks to the hydraulic drive system’s low inertia and overload protection. Off-season maintenance is limited to routine inspections, oil checking, and changing filters.

Just the beginning

Following a full season of operation at the Mawana plant, company officials decided to implement a similar drive system at a second plant. As with the Mawana Plant, the mill rolls are 78-in. long, with a 36-in. diameter.

This second plant was originally commissioned with a capacity of 3000 ton/day, and driven by dc motors through gear boxes. It was also decided to upgrade the mill’s capacity to 5000 ton/day and incorporate an auxiliary feeder drive (powered by an independent Hägglunds system) to ensure that the mill always operates at full torque and lowest speed in order to maximize extraction. This mill also runs at speeds to 5.5 rpm, and the feeder drive at 6.8. Respective power capacities are 750 W and 250 W. All four motors are Hgglunds Model MB1600.

The higher capacity would have required larger foundations with a conventional drive. But the hydraulic drive increased capacity without the need for any major reconstruction.

For more information on Hägglunds Drives, visit www.hagglunds.com, call (614) 527 7400, or e-mail [email protected].