Pneumatics Will Remain a Relevant Power Transmission Technology

Pneumatic systems continue to be the technology of choice in many applications as they offer a clean, efficient and cost-effective means of transmitting power.

The lower cost and longevity of pneumatic components help make them a more desirable option over hydraulic or electric actuators in many applications, said Jon Jensen (no relation to author), CFPPS, CFPECS & CFPAI, Industry Projects Manager – Energy at SMC Corporation of America in an interview with Power & Motion.

Pneumatic systems operate at lower pressures than hydraulics which reduces their manufacturing costs. They also require fewer components to install and maintain, helping to minimize their total cost of ownership. In addition, pneumatics can achieve the high speeds desired of many applications which further benefits their continued value in many system designs.

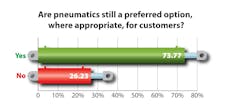

According to a survey of Power & Motion’s audience, 73% said pneumatics is still a preferred option for customers where appropriate.

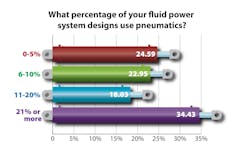

In conjunction, 34% indicated that 21% or more of their fluid power system designs use pneumatics. Almost 25% said 0-5% of their designs use pneumatics while close to 23% said 6-10% of their systems use it, demonstrating the continued value of pneumatic components and systems.

How Technology is Impacting Pneumatic Systems

Advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI) and machine learning (ML) are growing in use within many of the industries served by pneumatics, particularly the manufacturing sector. With them comes the ability to collect and analyze data, helping to better monitor machine performance and more.

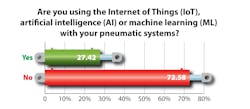

However, their direct impact on pneumatic systems appears to be limited at the moment. Just 27% of survey respondents said they were using IoT, AI or ML with their pneumatic systems while most, 72%, indicated they were not using them.

Those who are using these technologies noted benefits of doing so include the ability to provide predictive analytics, more precise control and connectivity of sensors and valves for position feedback. One respondent also mentioned there being more precise and better communication between components when these technologies are used with their pneumatic systems.

Although use of IoT, AI or ML may be limited currently, their use is likely to grow in the coming years as customers look to have more intelligence, analytics and monitoring integrated into their systems said Rex Bateman, Director of Engineering at SMC Corp. in an interview with Power & Motion. As the Industrial Internet of Things (IIoT) has become more ubiquitous, he said customers are looking for systems which are easier to maintain and remotely monitored to help prevent downtime.

In a webinar with Power & Motion, Frank Latino, Global Product Manager, Electric Automation at Festo Americas, said there are many benefits to deploying AI in fluid power applications such as improving maintenance and lowering energy consumption. Achieving these benefits is possible when AI is paired with IoT, edge computing and other technologies, he said.

The National Fluid Power Association (NFPA), which represents the hydraulics and pneumatics industry, finds the impact of technologies such as the IoT on fluid power designs significant enough at this point to expand its membership categories. In March 2024, it announced the creation of the new Controls, IoT and Data (CID) membership category.

NFPA recognizes the impact these technologies are having on fluid power systems and the need to engage with companies developing them to ensure the industry continues to meet the evolving needs of its various customer markets.

Integration of Electronics with Pneumatics is Increasing

The integration of electronics within pneumatic systems is increasing to help provide better performance and monitoring capabilities. Melissa Childers, Business Development Manager, Motion Systems Group, Pneumatic Division at Parker Hannifin, told Power & Motion that more customers are seeking feedback from their automation systems – many of which utilize pneumatics. This helps them to achieve higher levels of productivity.

She said monitoring, detecting and maintaining pneumatic systems through the inclusion of various electronic technologies, such as sensors, can help to decrease operating costs while increasing uptime.

SMC’s Bateman noted the integration of electronics with pneumatic systems has been a growing trend over the last few decades, and it continues to become easier to do so as technology advances. Today, more components are more of a hybrid than strictly electronic or pneumatic he said.

By integrating electronics, he said it is possible to get better control and feedback while maintaining the force, speed and cost benefits of pneumatics.

While there are many advantages to pairing electronics and pneumatics, there is a growing trend toward electric alternatives. Their use is of course dependent upon application needs; those requiring more controllability and precision are where electronic solutions may be the better option, said Bateman.

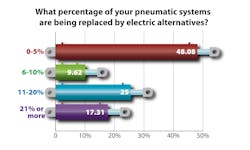

Power & Motion readers were almost evenly split between those who see their pneumatic system designs being replaced by electric alternatives and those who are not experiencing this. Forty eight percent said 0-5% of their pneumatic systems are being replaced and just 17% said 21% or more of their systems are being replaced with electric alternatives, indicating the transition away from pneumatics may not be as fast paced as some might think.

For those who do see a move toward electric alternatives, some of the industry drivers noted by respondents include the additional features available with electric options and their costs coming down. Others indicated the ease of control and precision possible with electric as well as the ability to use clean energy.

A Bright Future Remains for Pneumatic Systems

While there are many benefits to utilizing pneumatics, challenges remain for users of the technology as well. Chief among them, according to 29% of survey respondents, is knowing how best to maintain these systems.

One survey respondent noted the miniaturization of pneumatic system components has made them too small for people to work on while another said there is a lack of support for servo and proportional pneumatics.

Properly maintaining pneumatic systems is vital to ensuring overall machine performance. Greater incorporation of sensors, IoT and other technologies may help to overcome the challenges associated with maintaining pneumatics in the coming years. They enable the collection and analysis of performance data to make it easier to detect issues and address them before costly downtime occurs.

This will be increasingly important to enable as the number of skilled maintenance staff continues to decline.

Another 19% of respondents indicated it can be a challenge understanding when to use pneumatics. Determining whether to use hydraulics, pneumatics or electronics is dependent upon the application requirements – How much force is required? Are repeatability and precision important? Is safety a concern? These and many other factors should be taken into consideration to help determine technology choice.

Given the changing skill levels in fluid power and its related customer markets due to people retiring and a new generation of engineers entering the sector, the industry may need to consider increasing the amount of education it does on pneumatics and the applications for which they are a fit.

READ MORE: Sorting Out Linear Actuators

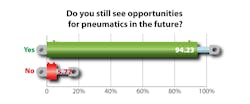

Despite the challenges, an overwhelming majority of survey respondents, 94%, said they still see opportunities for pneumatics in the future. Applications where respondents see pneumatics continuing to provide value include robotics, explosive environments, and brake systems.

One respondent noted pneumatics is still the simplest, least expensive way to control an actuator for two positions with high force. Another said applications where electric is not cost effective or appropriate due to the environmental conditions, such as those which are wet, are best suited to pneumatics.

Additional benefits noted by respondents which are aiding the continued use of pneumatics include their lightweight design and ability to provide rapid motion. As one respondent put it, pneumatic systems are “still the best option when intermittent bursts of power and speed are part of the requirement. A 1/4 in. poly hose can charge a receiver that can deliver multi-kilowatts of power to an inexpensive cylinder.”

These and other benefits noted by respondents indicate there is still a long life ahead for pneumatics and continued technological advancements for these systems will help to ensure their longevity.

About the Author

Sara Jensen

Executive Editor, Power & Motion

Sara Jensen is executive editor of Power & Motion, directing expanded coverage into the modern fluid power space, as well as mechatronic and smart technologies. She has over 15 years of publishing experience. Prior to Power & Motion she spent 11 years with a trade publication for engineers of heavy-duty equipment, the last 3 of which were as the editor and brand lead. Over the course of her time in the B2B industry, Sara has gained an extensive knowledge of various heavy-duty equipment industries — including construction, agriculture, mining and on-road trucks —along with the systems and market trends which impact them such as fluid power and electronic motion control technologies.

You can follow Sara and Power & Motion via the following social media handles:

X (formerly Twitter): @TechnlgyEditor and @PowerMotionTech

LinkedIn: @SaraJensen and @Power&Motion

Facebook: @PowerMotionTech

Leaders relevant to this article: